Abstract

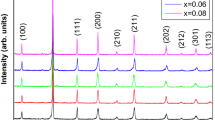

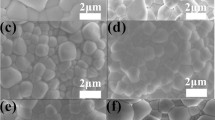

The present research study analyzes the consequences of the incorporation of rare earth ions on the pyroelectric, ferroelectric and piezoelectric, and luminescence properties of Ba0.85Ca0.12RE0.03Ti0.90Zr0.04Nb0.042O3 (BCRETZN) (where RE = Ce or Pr) ceramic composites synthesized by means of a solid-state process. Rietveld refinement of X-ray diffraction data and Raman spectra analysis confirmed the presence of tetragonal symmetry (P4mm) at room temperature. Two different exciting laser wavelengths have been employed to illuminate the RE3+ emission phenomenon. The involvement of the luminescence behavior in the “abnormal” Raman spectra was registered at 785 nm. The measurements as a function of the temperature of pyroelectric properties, ferroelectric cycles, strain-field cycles, and dielectric properties confirmed the occurrence the tetragonal-to-cubic (T–C) and orthorhombic-to-tetragonal (O–T) phase transition sequence. Compared to pure BaTiO3, the incorporation of RE-ions lowers the phase transition temperatures. The BCPrTZN compound leads to a larger decrease in O–T and T–C phase transition temperatures than the BCCeTZN compound. The presence of Ce3+ and Pr3+ ions inside these perovskite ceramics is likely to have significant technological applications in future multifunctional devices.

Similar content being viewed by others

Data availability

Data will be made available on request.

References

E. Hollenstein, M. Davis, D. Damjanovic, N. Setter, Appl. Phys. Lett. 87, 182905 (2005). https://doi.org/10.1063/1.2123387

P. Kantha, K. Pengpat, P. Jarupoom, U. Intatha, G. Rujijanagul, T. Tunkasiri, Curr. Appl. Phys. 9, 460–466 (2009). https://doi.org/10.1016/j.cap.2008.04.004

I. Nomel, J. Lelievre, L. Boyer, O.D. Panteix, P. Marchet, Ceram. Int. 48, 14697–14707 (2022). https://doi.org/10.1016/j.ceramint.2022.02.005

Z. Raddaoui, R. Brahem, A. Bajahzar, H.M. Albetran, J. Dhahri, H. Belmabrouk, J. Mater. Sci.: Mater. Electron. 32, 23333–23348 (2021). https://doi.org/10.1007/s10854-021-06818-1

Z. Raddaoui, R. Lahouli, S. El Kossi, J. Dhahri, H. Belmabrouk, A. Bajahzar, J. Mater. Sci.: Mater. Electron. 31, 4836–4849 (2020). https://doi.org/10.1007/s10854-020-03046-x

Z. Raddaoui, S. El Kossi, A.V. Trukhanov, A.L. Kozlovskiy, M.V. Zdorovets, J. Dhahri, J. Mater. Sci.: Mater. Electron. 32, 7366–7376 (2021). https://doi.org/10.1007/s10854-021-05446-z

A.S. Mischenko, Q. Zhang, J.F. Scott, R.W. Whatmore, N.D. Mathur, Science 311, 1270–1271 (2006). https://doi.org/10.1126/science.1123811

G.H. Haertling, J. Am. Ceram. Soc. 82, 797–818 (1999). https://doi.org/10.1111/j.1151-2916.1999.tb01840.x

G. Dai, S. Wang, G. Huang, G. Chen, B. Lu, D. Li, T. Tao, Y. Yao, B. Liang, S. Lu, Int. J. Appl. Ceram. Technol. 17, 1354–1361 (2020)

J. Buscaglia, C. Randall, J. Eur. Ceram. Soc. 40, 3744–3758 (2020). https://doi.org/10.1016/j.jeurceramsoc.2020.01.021

Z. Raddaoui, S. El Kossi, J. Dhahri, N. Abdelmoula, K. Taibi, RSC Adv. 9, 2412 (2019). https://doi.org/10.1039/c8ra08910h

H. Abdmouleha, I. Kriaaa, N. Abdelmoulaa, Z. Sassib, H. Khemakhema, J. Alloys Compd 878, 160355 (2021). https://doi.org/10.1016/j.jallcom.2021.160355

G. Singh, V.S. Tiwari, P.K. Gupta, Appl. Phys. Lett. 103, 202903 (2013)

W. Li, Z. Xu, R. Chu, P. Fu, G. Zang, J. Am. Ceram. Soc. 93, 2942–2944 (2010). https://doi.org/10.1111/j.1551-2916.2010.03907.x

W. Li, Z. Xu, R. Chu, P. Fu, G. Zang, Mater. Lett. 64, 2325–2327 (2010). https://doi.org/10.1016/j.matlet.2010.07.042

Y. Zhang, J. Glaum, C. Groh, M.C. Ehmke, J.E. Blendell, K.J. Bowman, M.J. Hoffman, J. Am. Ceram. Soc. 97, 2885–2891 (2014). https://doi.org/10.1111/jace.13047

Z. Wang, W. Li, R. Chu, J. Hao, Z. Xu, G. Li, J. Mater. Sci.: Mater. Electron. 17, 7569 (2017). https://doi.org/10.1007/s10854-017-7569-z

R. Hayati, M.A. Bahrevar, Y. Ganjkhanlou, V. Rojas, J. Koryza, J. Adv. Ceram. 8, 186–195 (2019). https://doi.org/10.1007/s40145-018-0304-2

I. Zouari, Z. Sassi, L. Seveyrat, N. Abdelmoula, L. Lebrun, H. Khemakhem, Ceram. Int. 44, 8018–8025 (2018). https://doi.org/10.1016/j.ceramint.2018.01.242

M. Bourguiba, Z. Raddaoui, W. Dimassi, M. Chafra, J. Dhahri, P. Marchet, M.A. Garcia, RSC Adv. 12, 10598 (2022). https://doi.org/10.1039/d2ra01068b

Z. Raddaoui, R. Lahouli, S.E.L. Kossi, J. Dhahri, K. Khirouni, K. Taibi, J. Alloys Compd. 771, 67–78 (2019). https://doi.org/10.1016/j.jallcom.2018.08.242

Y. El Hassan, A. Bendahhou, K. Chourti, F. Chaou, I. Jalafi, S. El Barkany, Z. Bahari, M.A. Salama, RSC Adv. 12, 33124 (2022). https://doi.org/10.1039/d2ra06758g

X.S. Patel, P. Sharma, R. Vaish, Phase Transit. 89, 1062–1073 (2016). https://doi.org/10.1080/01411594.2016.1144752

H. Kaddoussi, A. Lahmar, Y. Gagou, J.-L. Dellis, H. Khemakhem, M. El Marssi, Ceram. Int. 41, 15103–15110 (2015). https://doi.org/10.1016/j.ceramint.2015.08.080

I. Zouari, Z. Sassi, L. Seveyrat, N. Abdelmoula, L. Lebrun, H. Khemakhem, J. Alloys Compd. 825, 153859 (2020). https://doi.org/10.1016/j.jallcom.2020.153859

A.P.A. Moraes, A.G. Souza Filho, P.T.C. Freire, J. Mendes Filho, J.C. M’Peko, A.C. Hernandes, E. Antonelli, M.W. Blair, R.E. Muenchausen, L.G. Jacobsohn, W. Paraguassu, J. Appl. Phys. 109, 124102 (2011). https://doi.org/10.1063/1.3594710

Z. Raddaoui, S. El Kossi, B. Smiri, T. Al-shahrani, J. Dhahri, H. Belmabrouk, RSC Adv. 10, 23615 (2020). https://doi.org/10.1039/d0ra04033a

Z. Raddaoui, N. Kokanyan, M.D. Fontana, S.E. Kossi, J. Dhahri, J. Mol. Struct. 1230, 129939 (2021). https://doi.org/10.1016/j.molstruc.2021.129939

I. BejaouiOuni, D. Chapron, H. Aroui, M.D. Fontana, J. Appl. Phys. 121, 114102 (2017). https://doi.org/10.1063/1.4978507

F. Lawar, J. Belhadi, B. Asbani, B. Manoun, H. Kaddoussi, M. Courty, C. Boudaya, M. El Marssi, H. Khemakhem, A. Lahmar, J. Mater. Sci. Mater. Electron. 29, 18640–18649 (2018). https://doi.org/10.1007/s10854-018-9983-2

J. Hao, Y. Zhang, X. Wei, Angew. Chem. Int. Ed. 50, 6876–6880 (2011)

T. Mazon, A.C. Hernandes, A.G. Souza Filho, A.P.A. Moraes, A.P. Ayala, P.T.C. Freire, J.M. Filho, J. Appl. Phys. 97, 104113 (2005). https://doi.org/10.1063/1.1901834

Z. Abdelkafi, G. Khasskhoussi, N. Abdelmoula, H. Khemakhem, Ferroelectric Ceram. Int 41, 14839–14844 (2015). https://doi.org/10.1016/j.ceramint.2015.08.011

J. Pokorny, U.M. Pasha, L. Ben, O.P. Thakur, D.C. Sinclair, I.M. Reaney, J. Appl. Phys. 109, 114110 (2011). https://doi.org/10.1063/1.3592192

Q. Liu, J. Liu, D. Lu, W. Zheng, C. Hu, J. Alloys Compd 760, 31–41 (2018). https://doi.org/10.1016/j.jallcom.2018.05.089

H. Kaddoussi, N. Abdelmoulaa, Y. Gagou, D. Mezzane, H. Khemakhem, M. Elmarssi, Ceram. Int 40, 10255–10261 (2014). https://doi.org/10.1016/j.ceramint.2014.02.115

M. Runowskia, P. Woźnya, I.R. Martínb, V. Lavínb, S. Lisa, J. Lumin. 214, 116571 (2019). https://doi.org/10.1016/j.jlumin.2019.116571

J. Zhou, Y. Teng, X. Liu, Z. Ma, J. Qiu, J. Mater. Res. 26, 689–692 (2011). https://doi.org/10.1557/jmr.2010.84

M. Pereira, A.G. Peixoto, M.J.M. Gomes, J. Eur. Ceram. Soc. 21, 1353–1356 (2001). https://doi.org/10.1016/S0955-2219(01)00017-6

Q. Zhang, H. Sun, X. Wang, Y. Zhang, X. Li, J. Eur. Ceram. Soc. 34, 1439–1444 (2014). https://doi.org/10.1016/j.jeurceramsoc.2013.11.028

E. Siegel, K.A. Müller, Phys. Rev. B 20, 3587 (1979). https://doi.org/10.1103/PhysRevB.20.3587

M. Ganguly, S.K. Rout, T.P. Sinha, S.K. Sharma, H.Y. Park, C.W. Ahn, I.W. Kim, J. Alloys Compd. 579, 473–484 (2013). https://doi.org/10.1016/j.jallcom.2013.06.104

A. Lahmar, N. Pfeiffer, S. Habouti, M. Es-Souni, Ceram. Int. 41, 443–449 (2015). https://doi.org/10.1016/j.ceramint.2014.08.089

J. Yamauchi, M. Tsukada, S. Watanabe, O. Sugino, Phys. Rev. B 54, 5586 (1996). https://doi.org/10.1103/PhysRevB.54.5586

Acknowledgements

This work was supported by the Institute of Research on Ceramics (University of Limoges, France). The author would like to thank the Deanship of Scientific Research at Princess Nourah bint Abdulrahman University through the fast-track research funding program funded this research.

Author information

Authors and Affiliations

Contributions

ZR: conception, design of study. PM: data curation and writing—review and editing. MB: investigation, software. JL: data curation and writing. TA: data curation. HB: data curation and writing.

Corresponding authors

Ethics declarations

Competing interests

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Research involving human participants or animals

Not applicable. The study does not involve humans or animals.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Raddaoui, Z., Marchet, P., Bourguiba, M. et al. Effect of rare earth substitution on pyroelectric, ferroelectric, and piezoelectric properties lead-free Ba0.85Ca0.12RE0.03Ti0.90Zr0.04Nb0.042O3 (RE = Ce or Pr) ceramics. J Mater Sci: Mater Electron 34, 1736 (2023). https://doi.org/10.1007/s10854-023-11051-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10854-023-11051-z