Abstract

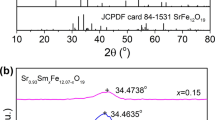

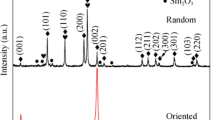

Sm2Fe17−xSixNy magnetic powder was synthesized through reduction–diffusion and mechanical milling processes. The influence of Si addition on the microstructure and magnetic properties of Sm2Fe17−xSixNy powder was discussed. Results showed that the formation of impurity α-Fe phase in Sm2Fe17−xSixNy powder during nitriding process was suppressed as x increased from 0 to 0.6. This phase transformation affected the nitrogen concentrations and mean particle size of Sm2Fe17−xSixNy powder and consequently improved the magnetic properties. In this study, Sm2Fe17−xSixNy magnetic powder with the highest maximum energy product of 38.37 MGOe was synthesized when x = 0.6. This powder has a relatively high coercivity of 14.92 kOe and a relatively large particle size of 2.49 μm.

Similar content being viewed by others

Data availability

All relevant data are within the paper.

References

H. Nakamura, Scripta Mater. 154, 273–276 (2018)

M.A. Oliver Gutfleisch, H. Willard, Ekkes Brück, Christina, S.G. Chen, Sankar, J. Ping, Liu, Adv. Mater. 23, 821–842 (2011)

H. Sepehri-Amin, Y. Une, T. Ohkubo, K. Hono, and M. Sagawa. Scripta Mater. 65, 396–399 (2011)

K. Hono, H. Sepehri-Amin, Scripta Mater. 67, 530–535 (2012)

T.G. Woodcock, Y. Zhang, G. Hrkac, G. Ciuta, N.M. Dempsey, T. Schrefl, O. Gutfleisch, D. Givord, Scr. Mater. 67, 536–541 (2012)

M. Katter, J. Wecker, C. Kuhrt, L. Schultz, J. Magn. Magn. Mater. 117, 419–427 (1992)

H.-L. Li, K. Takahashi, Y. Ujihira, M. Ishiwatari, K. Kobayashi, T. Iriyama, T. Konishi, Nuclear Instrum. Methods Phys. Res. B 76, 360–362 (1993)

H. Sun, T. Tomida, K. Makita, Y. Maehara, J. Alloys Compd. 237, 108–112 (1996)

D. Prabhu, H. Sepehri-Amin, C.L. Mendis, T. Ohkubo, K. Hono, S. Sugimoto, Scripta Mater. 67, 153–156 (2012)

N. Chris, N. Christodoulou, Komada, J. Alloys Compd. 222, 92–95 (1995)

J.M.D. Coey, H. Sun, J. Magn. Magn. Mater. 87, L251–L254 (1990)

J.M.D. Coey, J.F. Lawler, H. Sun, J.E.M. Allan, J. Appl. Phys. 69, 3007–3010 (1991)

T. Iriyama, K. Kobayashi, N. Imaoka, T. Fukuda, H. Kato, Y. Nakagawa, IEEE Trans. Magn. 28, 2326–2331 (1992)

B.P. Hu, X.L. Rao, J.M. Xu, G.C. Liu, Y.Z. Wang, X.L. Dong, D.X. Zhang, M. Cai, J. Appl. Phys. 74, 489–494 (1993)

M. Komuro, S. Kawamata, F. Tajima, H. Koharagi, J. Appl. Phys. 97, 10Q513 (2005)

J.M.D. Coey, J. Magn. Magn. Mater. (1995). https://doi.org/10.1016/0304-8853(94)00876-0

C.N. Christodoulou, T. Takeshita, J. Alloys Compd. 202, 173–182 (1993)

H. Kenta Takagi, K. Nakayama, Ozaki, J. Magn. Magn. Mater. 324, 2336–2341 (2012)

D.T. Zhang, M. Yue, J.X. Zhang, Powder Metall. 50, 215 (2007)

K. Takagi, R. Soda, M. jinno, W. Yamaguchi, J. Magn. Magn. Mater. 506, 166811 (2020)

H. Oda, K. Kondo, H. Uchida, Y. Matsumura, J. Appl. Phys. 34, L35 (1995)

M. Leonowicz, W. Kaszuwara, E. Januszewski, G. Mendoza, H.A. Davies, J. Paszula, J. Appl. Phys. 83, 6634 (1998)

T. Mashimo, X. Huang, S. Hirosawa, K. Makita, Y. Kato, S. Mitsudo, M. Motokawa, J. Magn. Magn. Mater. 210, 109 (2000)

T. Saito, M. Fukui, H. Takeishi, Scripta Mater. 53, 1117 (2005)

T. Maki, S. Sugimoto, T. Kagotani, K. Inomata, J. Akedo, Mater. Trans. 45, 369 (2004)

J. Ye, Y. Liu, G. Zhu, M. Chen, S. Gao, M. Tu, J. Alloys Compd. 428, 350 (2007)

H. Kenta Takagi, K. Nakayama, K. Ozaki, Kobayashi, J. Magn. Magn. Mater. 324, 1137–1341 (2012)

S. Yoshizawa, T. Ishikawa, I. Kaneko, S. Hayashi, A. Kawamoto, K. Ohmori, IEEE Trans. Magn. 35, 3340–3342 (1999)

T. Yamashita, S. Tsutsumi, T. Fukunaga, IEEE Trans. Magn. 40, 2059–2061 (2004)

K. Ohmori, S. Hayashi, T. Satoh, IEEE Trans. Magn. 41, 3850–3852 (2005)

K. Ohmori, S. Hayashi, S. Ypshizawa, J. Alloys Compd. 408–412, 1359–1362 (2007)

T. Kenji Ohmori, Ishikawa, J. Iron Steel Res. 1, 221–230 (2006)

K. Makita, S. Hirosawa, J. Alloys Compd. 260, 236–241 (1997)

S. Okada, E. Node, K. Takagi, Y. Fujikawa, Y. Enokido, C. Moriyoshi, Y. Kuroiwa, J. Alloys Compd. 804, 237–242 (2019)

S. Okada, K. Suzuki, E. Node, K. Takagi, K. Ozaki, Y. Enokido, J. Alloys Compd. 695, 1617–1632 (2017)

N. Imaoka, T. Iriyama, S. Itoh, A. Okamoto, T. Katsumata, J. Alloys Compd. 222, 73–77 (1995)

M. Matsuura, K. Yarimizu, Y. Osawa, N. Tezuka, S. Sugimoto, T. Ishikawa, Y. Yoneyama, J. Magn. Magn. Mater. 471, 310–314 (2019)

M. Endoh, M. Iwata, M. Tokunaga., J. Appl. Phys. 70, 6030–6032 (1991)

W.F. Li, X.C. Hu, B.Z. Cui, J.B. Yang, J.Z. Han, G.C. Hadjipanayis, J. Magn. Magn. Mater. 339, 71–74 (2013)

K. Peng, Y. Wu, G. Fang, G. Xu, C. Liu, J. Alloys Compd. 947, 169368 (2023)

S. Zheng, T. Jiang, X. Wei, Q. Cai, C. Chen, G. Fang, C. Liu, J. Phys. Chem. C 127, 1704–1711 (2023)

Acknowledgements

This research is supported by the ten thousand talents project of Zhejiang Province (2019R52056).

Funding

This work was supported by Ten Thousand Talents project of Zhejiang Province [2019R52056].

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation, data collection, and analysis were performed by LY, ZY, SY, ZY, HJ, HJ and JY. The first draft of the manuscript was written by LY, and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interest

The authors declare no conflicts of interest.

Research involving human and animal participants

This article does not contain any studies with human participants or animals performed by any of the authors.

Additional information

Publisher’s Note

Springer nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Yuping, L., Yujing, Z., Yongyang, S. et al. Synthesis of Sm2Fe17−xSixNy magnetic powder with high coercivity through reduction–diffusion and mechanical milling process. J Mater Sci: Mater Electron 34, 1594 (2023). https://doi.org/10.1007/s10854-023-11011-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10854-023-11011-7