Abstract

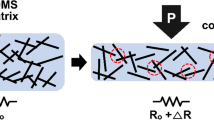

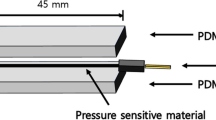

Polydimethylsiloxane (PDMS) is widely used as an elastic substrate for flexible pressure sensors. Functional materials integrated into the network of PDMS are usually able to enhance sensing performance. In this work, carbon nanotubes (CNTs) mixed with nano-zinc oxide (nano-ZnO) were used as conductive filler to prepare nano-ZnO/CNTs/PDMS active layer to assemble a flexible pressure sensor. At 0 ~ 10 kPa, nano-ZnO/CNTs/PDMS pressure sensor exhibits a sensitivity of 0.18 kPa−1 and a response time of 45.5 ms. The results confirm that the combination of CNTs and nano-ZnO provides the PDMS substrate with improved pressure sensing properties. Moreover, the nano-ZnO/CNTs/PDMS sensor maintains a good stability after 6000 cycles. After assembly, the nano-ZnO/CNTs/PDMS sensor could be used to monitor the movement of various body parts.

Similar content being viewed by others

Data availability

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

Z. Chen, R. Chen, C. Zhao et al., A novel medically imageable intelligent cellulose nanofibril-based injectable hydrogel for the chemo-photothermal therapy of tumors. Chem. Eng. J. 431(3), 133255 (2022)

B. Kuzubasoglu, E. Sayar, C. Cochrane et al., Wearable temperature sensor for human body temperature detection. J. Mater. Sci.: Mater. Electron. 32(4), 4784–4797 (2021)

K. Shen, K. Xu, M. Zhang et al., Multiple hydrogen bonds reinforced conductive hydrogels with robust elasticity and ultra-durability as multifunctional ionic skins. Chem. Eng. J. 451, 138525 (2023)

Z. Liu, J. Liu, J. Zhang et al., Highly compressible hydrogel sensors with synergistic long-lasting moisture, extreme temperature tolerance and strain-sensitivity properties. Mater. Chem. Front. 4(11), 3319–3327 (2020)

B. Ying, R. Chen, R. Zuo et al., An anti-freezing, ambient-stable and highly stretchable ionic skin with strong surface adhesion for wearable sensing and soft robotics. Adv. Func. Mater. 31(42), 2104665 (2021)

D. Choi, J. Bae, S. Lee et al., Emotion-interactive empathetic transparent skin cushion with tailored frequency-dependent hydrogel-plasticized nonionic polyvinyl chloride interconnections. Chem. Eng. J. 442, 136142 (2022)

G. Schwartz, B. Tee, J. Mei et al., Flexible polymer transistors with high pressure sensitivity for application in electronic skin and health monitoring. Nat. Commun. 4, 1859 (2013)

W. Xue, G. Yang, X. Zuo et al., Silk-molded flexible, ultrasensitive, and highly stable electronic skin for monitoring human physiological signals. Adv. Mater. 26(9), 1336–1342 (2014)

Y. Xiao, Research on flexible tactile sensors based on conductive composites (University of Electronic Science and Technology of China, Chengdu, 2021), pp.18–21

K. Takei, T. Takahashi, J. Ho et al., Nanowire active-matrix circuitry for low-voltage macroscale artificial skin. Nat. Mater. 9(10), 821–826 (2010)

B. Zhu, Z. Niu, H. Wang et al., Microstructured graphene arrays for highly sensitive flexible tactile sensors. Small 10(18), 3625–3631 (2014)

C. Sheng, S. Yi, X. Feng, Flexible and highly sensitive resistive pressure sensor based on carbonized crepe paper with corrugated structure. ACS Appl. Mater. Interfaces. 10(40), 34646–34654 (2018)

M. Jian, K. Xia, Q. Wang, et al., Flexible and highly sensitive pressure sensors based on bionic hierarchical structures. Adv. Funct. Mater. 27(9), 1606066 (2017)

C. Deng, L. Pan, R. Cui et al., Wearable strain sensor made of carbonized cotton cloth. J. Mater. Sci.: Mater. Electron. 28(4), 3535–3541 (2017)

C. Liu, J. Choi, Analyzing resistance response of embedded PDMS and carbon nanotubes composite under tensile strain. Microelectron. Eng. 117, 1–7 (2014)

D. Kumar, P. Jha, A. Chouksey et al., Flexible single walled nanotube based chemical sensor for 2,4-dinitrotoluene sensing. J. Mater. Sci.: Mater. Electron. 29(8), 6200–6205 (2018)

C. Jin, D. Liu, M. Li et al., Application of highly stretchy PDMS-based sensing fibers for sensitive weavable strain sensors. J. Mater. Sci.: Mater. Electron. 31(6), 4788–4796 (2020)

H. Zhang, X. Sun, M. Hubbe et al., Flexible and pressure-responsive sensors from cellulose fibers coated with multiwalled carbon nanotubes. ACS Appl. Electron. Mater. 1(7), 1179–1188 (2019)

X. Zhang, D. Xiang, W. Zhu et al., Flexible and high-performance piezoresistive strain sensors based on carbon nanoparticles@polyurethane sponges. Compos. Sci. Technol. 200, 108437 (2020)

Q. Huang, Y. Jiang, Z. Duan et al., Protrusion microstructure-induced sensitivity enhancement for zinc oxide-carbon nanotube flexible pressure sensors. ACS Appl. Electron. Mater. 3(12), 5506–5513 (2021)

A. Ahmed, Y. Jia, Y. Huang et al., Preparation of PVDF-TrFE based electrospun nanofibers decorated with PEDOT-CNT/rGO composites for piezo-electric pressure sensor. J. Mater. Sci.: Mater. Electron. 30(37), 14007–14021 (2019)

A. Ahmed, Y. Jia, H. Deb et al., Ultra-sensitive all organic PVDF-TrFE E-spun nanofibers with enhanced β-phase for piezoelectric response. J. Mater. Sci.: Mater. Electron. 33(7), 3965–3981 (2022)

K. Zhang, Z. Lin, Highly sensitive ethanol sensor based on zinc oxide-based nanomaterials with low power consumption. J. Mater. Sci.: Mater. Electron. 32(13), 17395–17405 (2021)

S. Chen, J. Luo, X. Wang et al., Fabrication and piezoresistive/piezoelectric sensing characteristics of carbon nanotube/pva/nano-zno flexible composite. Sci. Rep. 10(1), 8895 (2020)

H. Sadiq, H. Hui, S. Huang et al., A flexible pressure sensor based on PDMS-CNTs film for multiple applications. IEEE Sens. J. 22(4), 3033–3039 (2022)

J. Wang, C. Zhang, D. Chen et al., Fabrication of a sensitive strain and pressure sensor from gold nanoparticle-assembled 3D-interconnected graphene microchannel-embedded PDMS. ACS Appl. Mater. Interfaces. 12(46), 51853–51854 (2020)

Y. Zhao, J. Liu, H. Li et al. An ultra-sensitive gas pressure sensor based on tapered fiber coated with PDMS film working at TAP. Opt. and Laser Technol. 151, 107998 (2022)

J. Li, G. Zhou, Y. Hong et al., Highly sensitive, flexible and wearable piezoelectric motion sensor based on PT promoted β-phase PVDF. Sens. Actuators A Phys. 337, 113415 (2022)

N. Serra, T. Maeder, P. Ryser, Piezoresistive effect in epoxy-graphite composites. Sens. Actuators A 186, 198–202 (2012)

N. Hu, Y. Karube, C. Yan et al., Tunneling effect in a polymer/carbon nanotube nanocomposite strain sensor. Acta Mater. 56(13), 2929–2936 (2008)

J. Daniel, M. Debkishore, P. Kevin et al., A highly elastic, capacitive strain gauge based on percolating nanotube networks. Nano Lett. 12(4), 1821–1825 (2012)

F. Azhari, N. Banthia, Cement-based sensors with carbon fibers and carbon nanotubes for piezoresistive sensing. Cement Concr. Compos. 34(7), 866–873 (2012)

V. Borjanovic, L. Bistricic, I. Vlasov et al., Influence of proton irradiation on the structure and stability of poly(dimethylsiloxane) and poly(dimethylsiloxane)-nanodiamond composite. J. Vac. Sci. Technol., B 27(6), 2396–2403 (2009)

M. Odziemkowski, J. Koziel, D. Irish et al., Sampling and raman confocal microspectroscopic analysis of airborne particulate matter using poly(dimethylsiloxane) solid-phase microextraction fibers. Anal. Chem. 73(13), 3131–3139 (2001)

L. Jayes, A. Hard, C. Séné et al., Vibrational spectroscopic analysis of silicones: a fourier transform-Raman and inelastic neutron scattering investigation. Anal. Chem. 75(4), 742 (2003)

V. Borjanović, L. Bistričić, L. Mikac et al., Polymer nanocomposites with improved resistance to ionizing radiation. J. Vacuum Sci. Technol. B. 30(4), 041803 (2012)

M. Dresselhaus, G. Dresselhaus, R. Saito et al., Raman spectroscopy of carbon nanotubes. Phys. Rep. 409(2), 47–99 (2005)

LM. Johnson, L. Gao, CW. Shields IV et al., Elastomeric microparticles for acoustic mediated bioseparations. J. Nanobiotechnol. 11, 22 (2013)

S. Hamouni, O. Arous, D. Abdessemed et al., Alcohol and alkane organic extraction using pervaporation process. Macromol. Symp. 386(1), 1800247 (2019)

Y. Ma, Y. Yue, H. Zhang et al., 3D synergistical MXene/reduced graphene oxide aerogel for a piezoresistive sensor. ACS Nano 12, 3209–3216 (2018)

Acknowledgements

The authors gratefully acknowledge the support of the projects of Innovation Team Project of Zhuhai City (No. ZH0405190005PWC), Zhuhai Industry-University-Institute Cooperation (No. 2220004002990), Sichuan Natural Science Foundation (No. 2022NSFSC0654) and UESTC-Sichuan Cancer Hospital 2021 Medical-engineering Oncology Innovation Fund (No. ZYGX2021YGCX013).

Funding

The authors declare that no funds, grants, or other support were received during the preparation of this manuscript.

Author information

Authors and Affiliations

Contributions

Material preparation, data collection, and analysis were performed by ZX, SW, and JL. The first draft of the manuscript was written by JL. Project administration, conceptualization, and formal analysis were performed by WH, ZN, and YH. Visualization, Investigation, and Methodology were performed by YC, YH, GZ, and YT. JZ helped answer the reviewer comments and modified the English expression. All authors read and approved the final manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors have no relevant financial or non-financial interests to disclose.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Chen, Y., Li, J., Hong, Y. et al. Fabrication and characterization of nano-ZnO/CNTs/PDMS flexible pressure sensor. J Mater Sci: Mater Electron 34, 1600 (2023). https://doi.org/10.1007/s10854-023-10966-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10854-023-10966-x