Abstract

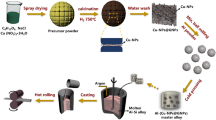

With the rapid development of the 3rd semiconductors, the metal nanoparticles are investigated to be applied in the die-attached interconnect materials. However, the organic solvent used in the nanoparticle paste needs to be addressed. In this work, we adopted the liquid phase reduction method to synthesize Cu–Ag core–shell micro/nano-mixed particles (Cu@Ag MNPs), which achieved better anti-oxidation properties than Cu MNPs. Due to the suitable boiling point and viscosity, the electrical properties and hardness of the sintered films prepared by polyethylene glycol 400 (PEG-400) are better than those of ethylene glycol and α-terpineol. The electrical properties reach 43.82 µΩ cm and the hardness reach 61.3 HV at 300 °C. The shear strength of the joint sintered by Cu@Ag MNPs paste with PEG-400 can reach 20.14 MPa at 300 °C. Besides, the sintered Cu@Ag MNPs film exhibits a denser structure than Ag MNPs and Cu MNPs film. Therefore, Cu@Ag MNPs have great development prospects in the 3rd semiconductors.

Similar content being viewed by others

Data availability

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

R.T. Yadlapalli, A. Kotapati, R. Kandipati, Int. J. Energy Res. 9, 45 (2021)

B. Zhang, M. Ghassemi, Y. Zhang, IEEE Trans. Dielectr. Electr. Insul. 1, 28 (2021)

Y. Zhang, A. Zubair, Z. Liu, Semicond. Sci. Technol. 5, 36 (2021)

J.Y. Wen, Y.H. Tian, C.J. Hang, Nanomaterials. 9, 960 (2019)

M.Y. LI, Y. Xiao, Z.H. Zhang, ACS Appl. Mater. Interfaces. 7, 9157 (2015)

Y. Zhou, G.M. Zhang, T. Xu, ACS Biomater. Sci. Eng. 6, 2770 (2020)

M.A. Zakaria, A.A. Menazea, A.M. Mostafa, Surf. Interfaces. 19, 100438 (2020)

I.X. Yin, J. Zhang, I.S. Zhao, Int. J. Nanomen. 15, 2555 (2020)

J. Ding, J. Liu, Q.Y. Tian, Nanoscale Res. Lett. 11, 1 (2016)

A. Rantamaki, J. Lindfors, M. Silvennoinen, PTL 25, 1062 (2013)

L. Canham, A. Nassiopoulou, V. Parkhutik, Phys. Status Sulidi A 197, 3 (2003)

X. Yu, J.J. Li, T. Shi, J. Alloy Compd. 709, 700 (2017)

S.C. Fu, Y.H. Mei, G.Q. Lu, Mater. Lett. 128, 42 (2014)

S. Wang, H.J. Ji, M.Y. Li, Mater. Lett. 85, 61 (2012)

S. Wang, M.Y. Li, H.J. Ji, Scripta Mater. 69, 789 (2013)

Y. Akada, H. Tatsumi, T. Yamaguchi, Mater. trans. 49, 1537 (2008)

K. Andritsos, L. Theodorakos, F. Zacharatos, Appl. Surf. Sci. 506, 144968 (2020)

B. Liao, H. Wang, L. Kang, J. Mater. Sci-Mater EL. 32, 5680 (2021)

P. Yi, K. Xiao, C.F. Dong, Bioelectrochemistry. 119, 203 (2018)

K.S. Kim, J.O. Bang, S.B. Jung, Curr. Appl. Phys. 13, S190–S194 (2013)

K.S. Kim, Y.T. Kwon, Y.H. Choa, S.B. Jung, Microelectron. Eng. 106(jun), 27–32 (2013)

R. Riva, C. Buttay, B. Allard, P. Bevilacqua, Microelectron. Reliab. 53(9–11), 1592–1596 (2013)

B.I. Noh, J.W. Yoon, K.S. Kim, Y.C. Lee, S.B. Jung, J. Electron. Mater. 40(1), 35–41 (2011)

C.H. Tsou, K.N. Liu, H.T. Lin, F.Y. Ouyang, J. Electron. Mater. 45(12), 1–7 (2016)

G.Q. Lu, C. Yan, Y.H. Mei, X. Li, Mater. Chem. and Phys. 151, 18–21 (2015)

W.H. Lin, C.H. Tsou, F.Y. Ouyang, J. Mater. Sci-Mater EL. 29(21), 18331–18342 (2018)

Z. Feng, C.R. Marks, A. Barkatt, Oxid. met. 60(5–6), 393–408 (2003)

C.H. Ryu, S.J. Joo, H.S. Kim, Thin Solid Films. 675(APR1), 23–33 (2019)

H.J. Park, Y. Jo, M.K. Cho, Nanoscale. 10, 1039 (2018)

S.J. Joo, M.H. Yu, E.B. Jeon, H.S. Kim, Compos. Sci. and Technol. 142(Apr12), 189–197 (2017)

Y. Gao, W.L. Li, C.T. Chen, H. Zhang, J.T. Jiu, C.F. Li, S. Nagao, K. Suganuma, Mater Des. 160(DEC), 1265–1272 (2018)

E.B. Choi, J.H. Lee, J. Alloys Compd. 689, 952–958 (2016)

S.J. Kim, E.A. Stach, C.A. Handwerker, Appl. Phys. Lett. 96, 144101 (2010)

W.C. Yang, W. Zheng, S.W. Hu, M.Y. Li, Mater. Let. 299, 129781 (2021)

X. Yu, J.J. Li, T.L. She, C.L. Cheng, G.L. Liao, J.H. Fan, T.X. Li, Z.R. Tang, J. Alloys Compd. 724, 365–372 (2017)

Y. Huang, F.S. Wu, Z. Zhou, L.Z. Zhou, H. Liu, Nanotechnology. 31(17) (2020)

M. Grouchko, A. Kamyshny, S. Magdassi, J. Mater. Chem. 19, 3057 (2009)

C. Lee, N.R. Kim, J. Koo, Y.J. Lee, H.M. Lee, Nanotechnology. 26(45), 455601 (2015)

J. Kähler, N. Heuck, G. Palm, A. Stranz, A. Waag, E. Peiner, IEEE 1–7 (2011)

J. Jiu, H. Zhang, S. Koga, S. Nagao, K. Suganuma, J. Mater. Sci-Mater EL. 26, 7183–7191 (2015)

Y.Y. Dai, M.Z. Ng, P. Anantha, Y.D. Lin, Z.G. Li, C.L. Gan, C.S. Tan, Appl. Phys. Lett. 108(26), 263103 (2016)

Y. Mou, J.X. Liu, H. Cheng, Y. Peng, M.X. Chen, Jom. 71, 9 (2019)

K. Suganuma, S. Sakamoto, N. Kagami, S. Soichi, K. Noriko, W. Daisuke, K. Keunsoo, N Masaya Microelectron Reliab. 52, 35–380 (2012)

M. Kuramoto, S. Ogawa, M. Niwa, K.S. Kim, K. Suganuma, IEEE T Comp Pack and Man. 1(5), 653–659 (2011)

D. Tomotoshi, H. Kawasaki, Nanomaterials. 10(9), 1689 (2020)

E.B. Choi, J.H. Lee, Appl. Surf. Sci. 546, 149156 (2021)

W. Liu, H. Wang, K.S. Huang, C.M. Wang, A.T. Wu, J. Taiwan. Inst. Chem. E. 125, 394–401 (2021)

L.J. Guo, W. Liu, C Q. Wang Mater. Lett. 282, 128845 (2021)

L.J. Guo, W. Liu, X.L. Ji, Y. Zhong, C.J. Hang, C.Q. Wang, ACS Appl. Electron. Ma. 4(7), 3457–3469 (2022)

T. Ogura, T. Yagishita, S. Takata, T. Fujimoto, A Hirose Mater. Trans. 54(6), 860–865 (2013)

Q. Gao, W. Zhou, Z.H. Ji, X.B. Wang, Z.D. Xia, F. Guo, ICEPT (2022). https://doi.org/10.1109/ICEPT56209.2022.9873105

Z.Z. Fang, H.T. Wang, X. Wang, V. Kumar, Ceram. Trans. 209, 389 (2010)

Funding

This study was funded by the National Natural Science Foundation of China (Grant No. 61904008), Beijing Municipal Natural Science Foundation (No. KZ202210005002) and National Natural Science Foundation of China (Grant No. 52001013).

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation, data collection and analysis were performed by WZ, ZX, XW, YW, ZY and FG. The first draft of the manuscript was written by QG and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors have no relevant financial or non-financial interests to disclose for this article.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Gao, Q., Zhou, W., Xia, Z. et al. Investigation of ethylene glycol, α-terpineol, and polyethylene glycol 400 on the sintering properties of Cu–Ag core–shell micro/nano-mixed paste. J Mater Sci: Mater Electron 34, 1585 (2023). https://doi.org/10.1007/s10854-023-10965-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10854-023-10965-y