Abstract

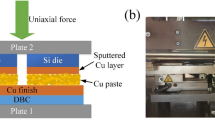

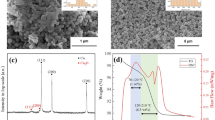

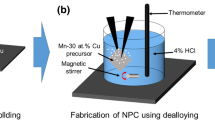

Copper paste sintering has great potential for WBG (wide bandgap) semiconductor packaging, but the problems of copper susceptibility to oxidation and high sintering temperatures have hindered its development. A micron copper paste suitable for low-temperature sintering was successfully formulated using the synergistic effect of metal organic decomposition (MOD) ink and ascorbic acid (AA) to achieve high shear strength sintered joints. During the sintering process, AA acted as a reducing agent to effectively remove oxide on the surface of the Cu microparticles (MPs), while the decomposition process of MOD was facilitated by the reduction products. The diffusion channels formed by the decomposed nanoparticles connect the Cu-MPs, forming dense sintered joints. At a sintering temperature of 250 °C, the combination of MOD and AA in the paste resulted in a significant improvement in the shear strength of the sintering joints, reaching 102.2 MPa. This is in contrast to the addition of only MOD or AA, which resulted in a shear strength of less than 5 MPa. Furthermore, the strength of the sintered joints was increased to 128.1 MPa after storage at 250 °C for 1000 h. At a sintering temperature of 210 °C, the strength could still reach 47.6 MPa, which was approximately double the strength of traditional Sn-based solder joints. This has greater practical significance for the fabrication of high-strength bonded joints and the expansion of the sintering process window.

Similar content being viewed by others

Data availability

The datasets supporting the results of this article are included within the article.

References

H. Yan, Y.H. Mei, X. Li, C. Ma, G.Q. Lu, IEEE Trans. Electron. Devices 65, 4499–4505 (2018)

H. Okumura, J. Japanese, Appl. Physics, part 1 Regul. Pap Short. Notes Rev. Pap. 45, 7565 (2006)

V.R. Manikam, K.Y. Cheong, IEEE Trans. Components Packag Manuf. Technol. 1, 457–478 (2011)

C. Chen, H.M. Tong, K.N. Tu, Annu. Rev. Mater. Res. 40, 531 (2010)

H. Zhang, J. Minter, N.C. Lee, J. Electron. Mater. 48, 201–210 (2019)

M. Abtew, G. Selvaduray, Mater. Sci. Eng. R Rep. 27, 95 (2000)

Z. Shen, R.W. Johnson, M.C. Hamilton, IEEE Trans. Electron. Devices. 62, 346 (2015)

V. Chidambaram, J. Hattel, J. Hald, Microelectron. Eng. 88, 981 (2011)

J.E. Lee, K.S. Kim, K. Suganuma, J. Takenaka, K. Hagio, Mater. Trans. 46, 2413 (2005)

A. Hu, J.Y. Guo, H. Alarifi, G. Patane, Y. Zhou, G. Compagnini, C.X. Xu, Appl. Phys. Lett. 97, 2008 (2010)

X. Wang, Y. Mei, X. Li, M. Wang, Z. Cui, G.Q. Lu, J. Alloys Compd. 777, 578 (2019)

H. Zhang, Z. Zhao, G. Zou, W. Wang, L. Liu, G. Zhang, Y. Zhou, Microelectron. Reliab. 94, 46 (2019)

Y. Morisada, T. Nagaoka, M. Fukusumi, Y. Kashiwagi, M. Yamamoto, M. Nakamoto, J. Electron. Mater. 39, 1283 (2010)

J.J. Li, C.L. Cheng, T.L. Shi, J.H. Fan, X. Yu, S.Y. Cheng, G.L. Liao, Z.R. Tang, Mater. Lett. 184, 193 (2016)

W. Li, H. Zhang, Y. Gao, J. Jiu, C.F. Li, C. Chen, D. Hu, Y. Goya, Y. Wang, H. Koga, S. Nagao, K. Suganuma, J. Mater. Chem. C 5, 1155 (2017)

Y. Zuo, S. Carter-Searjeant, M. Green, L. Mills, S.H. Mannan, Adv. Powder Technol. 31, 4135 (2020)

Y. Gao, W. Li, C. Chen, H. Zhang, J. Jiu, C.F. Li, S. Nagao, K. Suganuma, Mater. Des. 160, 1265 (2018)

X. Liu, H. Nishikawa, Scr. Mater. 120, 80 (2016)

J. Li, Y. Xu, X. Zhao, Y. Meng, Z. Yin, Y. Wang, T. Suga, ECS J. Solid State Sci. Technol. 10, 054004 (2021)

J. Liu, Y. Mou, J. Liu, Y. Peng, M. Chen, Nanoscale Adv. 3950, 1 (2022)

C. Schwarzer, L.M. Chew, T. Stoll, J. Franke, M. Kaloudis, CIPS 2020; 11th International Conference on Integrated Power Electronics Systems, p. 596 (2020)

S. Kwon, T.I. Lee, H.J. Lee, S. Yoo, Mater. Lett. 269, 127656 (2020)

W. Yang, E.J.W. List-Kratochvil, C. Wang, J. Mater. Chem. C 7, 15098 (2019)

X. Zeng, P. He, M. Hu, W. Zhao, H. Chen, L. Liu, J. Sun, J. Yang, Nanoscale. 14, 16003 (2022)

J. Lee, B. Lee, S. Jeong, Y. Kim, M. Lee, Thin Solid Films. 564, 264 (2014)

S.K. Tam, K.Y. Fung, K.M. Ng, J. Mater. Sci. 52, 5617–5625 (2017)

T. Yonezawa, H. Tsukamoto, Y. Yong, M.T. Nguyen, M. Matsubara, RSC Adv. 6, 12048 (2016)

W. Li, S. Cong, J. Jiu, S. Nagao, K. Suganuma, J. Mater. Chem. C 4, 8802 (2016)

Y. Gao, Y. bo Xiao, Z.Q. Liu, Y. Liu, R. Sun, J. Mater. Sci. Mater. Electron. 33, 3576 (2022)

Y. Yuan, H. Wu, J. Li, P. Zhu, R. Sun, J. Alloys Compd. 570, 151220 (2021)

S. Jingyan, L. Yuwen, W. Zhiyong, W. Cunxin, J. Pharm. Biomed. Anal. 77, 116 (2013)

Y.H. Choi, S.H. Hong, Langmuir. 31, 8101 (2015)

D.H. Shin, S. Woo, H. Yem, M. Cha, S. Cho, M. Kang, S. Jeong, Y. Kim, K. Kang, Y. Piao, ACS Appl. Mater. Interfaces. 6, 3312 (2014)

Acknowledgements

The authors gratefully acknowledge the financial support from Key Research and Development Program of Heilongjiang (GZ20210086), National Natural Science Foundation of China (51174069) and National Key Research and Development Program of China (2021YFB3202500).

Author information

Authors and Affiliations

Contributions

Quan Sun is responsible for data curation, validation, formal analysis, investigation, and draft preparation. Yang Liu is responsible for conceptualization and methodology. Jing Zhang and Jicun Lu are responsible for reviewing and guidance. Ke Li is responsible for the technical support and discussion.

Corresponding author

Ethics declarations

Conflict of interest

The article does not have a conflict of interest with any other unit, institution or any individual.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Sun, Q., Liu, Y., Zhang, J. et al. Fabrication of high reliability Cu joints at low temperatures using synergistic effect of organic composition for power device packaging. J Mater Sci: Mater Electron 34, 1595 (2023). https://doi.org/10.1007/s10854-023-10951-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10854-023-10951-4