Abstract

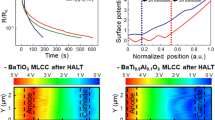

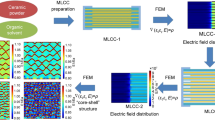

Ultra-thin base metal electrodes-multilayered ceramic capacitors (BME-MLCCs) with high volume capacitance are considered to be a charming device for a diverse range of electric applications. Here, we fabricated the MLCCs with ultra-thin layer of ~ 1.2 μm and a high capacitance of ~ 47 μF via high oxygen re-oxidation process. Defect chemistry analysis of the re-oxidation process reveals that about 1 nm thick for inter-diffusion layer between Ni and BaTiO3 appeared in higher oxygen re-oxidation process compared with lower oxygen re-oxidation process dominated by 3 nm thick for inter-diffusion layer. The results show that oxygen vacancy concentration is decreased when oxygen partial pressures of re-oxidation rise from 10–6 to 10–4 atm. In addition, the Schottky barrier at the BaTiO3(BT)–Ni interface increased from 1.30 to 1.82 eV, and the amount of oxygen (x) in BaTiOx at the interface decreased from 3 to 2.75, with a smaller decrease, which is conducive to the improvement of the overall reliability of MLCCs. The final results show that the MLCCs with high oxygen re-oxidation process demonstrated a high breakdown voltage of 52.74 V/μm and superior reliability at 2.5 V and 105 °C. This work demonstrates a strategy of effectively improving the reliability of BME-MLCCs with high capacitances.

Similar content being viewed by others

Data availability

All data generated or analyzed during this study are included in this published article (and its supplementary information files).

References

G. Yasin, S. Ibrahim, S. Ibraheem, J. Mater. Chem. A. 9(34), 18222–18230 (2021)

M. Nadeem, G. Yasin, M. Arif, Chem. Eng. J. 409, 128205 (2021)

S. Ullah, G. Yasin, A. Ahmad, Inorg. Chem. Front. 7(8), 1750–1761 (2020)

R. Iqbal, G. Yasin, M. Hamza, Coordin. Chem Rev. 447, 214152 (2021)

M.H.A. Mhareb, Y. Slimani, Y.S.A. Lajerami, Ceram. Int. 46(18), 28877–28886 (2020)

S.R. Yousefi, A. Sobhani, H.A. Alshamsi, Rsc. Adv. 11(19), 11500–11512 (2021)

S.R. Yousefi, O. Amiri, Ultrason. Sonochem. 58, 104–619 (2019)

S.R. Yousefi, O. Amiri, M. Salavati-Niasari, Ultrason. Sonochem. 58, 104–110 (2019)

S.R. Yousefi, A. Sobhani, M. Salavati-Niasari, Adv. Powder. Technol. 28(4), 1258–1262 (2017)

S.R. Yousefi, D. Ghanbari, M. Salavati-Niasari, J. Mater. Sci-Mater. El. 27, 1244–1253 (2016)

P. Mehdizadeh, M. Jamdar, M.A. Mahdi, Arab. J. Chem. 1, 104–106 (2023)

F.Z. Yao, Q. Yuan, Q. Wang, H. Wang, Nanoscale 12, 17165–17184 (2020)

K. Hong, T.H. Lee, J.M. Suh, S.H. Yoon, H.W. Jang, J. Mater. Chem. C. 7, 9782–9802 (2019)

C.Q. Zhu, Z.M. Cai, L.M. Guo, L.T. Li, X.H. Wang, J. Am. Ceram. Soc. 104(1), 273–283 (2021)

Z.B. Tian, X.H. Wang, H.L. Gong, T.H. Song, K.H. Hur, L.T. Liz, J. Am. Ceram. Soc. 94(4), 973–977 (2011)

G. Arlt, D. Hennings, G. De, J. Appl. Phys. 58(4), 1619–1625 (1985)

A.V. Polotai, A.V. Ragulya, C.A. Randall, Ferroelectrics 288(1), 93–102 (2003)

S.S. Park, Ferroelectrics 406(1), 75–82 (2010)

Z. Cai, X. Wang, L. Li, Adv. Theor. Simul. 2(4), 1800179 (2019)

C. Neusel, H. Jelitto, D. Schmidt, R. Janssen, F. Felten, G.A. Schneider, J. Eur. Ceram. Soc. 35(1), 113–123 (2015)

A. Honda, S. Higai, Y. Motoyoshi, N. Wada, H. Takagi, Jpn. J. Appl. Phys. 50(92), 09NE01 (2011)

D.I. Woodward, I.M. Reaney, G.Y. Yang, E.C. Dickey, C.A. Randall, Appl. Phys. Lett. 84(23), 4650–4652 (2004)

T. Hoshina, R. Sase, J. Nishiyama, H. Takeda, T. Tsurumi, Jpn. J. Appl. Phys. 126(5), 263–268 (2018)

Y. Mizuno, T. Hagiwara, H. Kishi, Jpn. J. Appl. Phys. 115(1342), 360–364 (2007)

G. Okuma, N. Saito, K. Mizuno, Y. Iwazaki, H. Kishi, A. Takeuchi, M. Uesugi, K. Uesugi, F. Wakai, Acta Mate. 206, 116605 (2021)

M.R. Opitz, K. Albertsen, J.J. Beeson, D.F. Hennings, J.L. Routbort, C.A. Randall, J. Am. Ceram. Soc. 86(11), 1879–1884 (2003)

Z.M. Cai, C.Q. Zhu, H.X. Wang, P.Y. Zhao, L.L. Chen, L.T. Li, X.H. Wang, J. Mater. Chem. A 7(24), 14575–14582 (2019)

A. Morelli, G. McLaughlin, M. Strawhorne, J.A. Byrne, P. Lemoine, A.C.S. Appl, Energy Mater. 3(10), 4649–4656 (2021)

Z.L. Gui, Y.L. Wang, L.T. Li, Ceram. Int. 30(7), 1275–1278 (2004)

G.Y. Yang, S.I. Lee, Z.J. Liu, C.J. Anthony, E.C. Dickey, Z.K. Liu, C.A. Randall, Acta Mater. 54(13), 3513–3523 (2006)

A.V. Polotai, G.Y. Yang, E.C. Dickey, C.A. Randall, J. Am. Ceram. Soc. 90(12), 3811–3817 (2007)

A.V. Polotai, I. Fujii, D.P. Shay, G.Y. Yang, E.C. Dickey, C.A. Randall, J. Am. Ceram. Soc. 91(8), 2540–2544 (2008)

A.V. Polotai, T.H. Jeong, G.Y. Yang, E.C. Dickey, C.A. Randall, P. Pinceloup, A.S. Gurav, J. Electroceram. 23(1), 6–12 (2009)

Y.C. Wu, S.F. Wang, D.E. McCauley, M.S.H. Chu, H.Y. Lu, J. Am. Ceram. Soc. 90(9), 2926–2934 (2007)

J. Weiss, J. Mater. Sci. 23(6), 2195–2204 (1988)

C.Q. Zhu, Q.C. Zhao, Z.M. Cai, L.M. Guo, L.T. Li, X.H. Wang, J. Alloy. Compd. 829, 154496 (2020)

F.A. Rabuffetti, R.L. Brutchey, J. Am. Ceram. Soc. 134(22), 9475–9487 (2012)

X.Q. Jin, D.Z. Sun, M.J. Zhang, Y.D. Zhu, J.J. Qian, J. Electroceram. 22(1), 285–290 (2009)

A.F. Carley, P.R. Chalker, J.C. Riviere, M.W. Roberts, J. Chem. Soc. Faraday Trans. 83(2), 351–370 (1987)

S.A. Nasser, Appl. Surf. Sci. 157(1–2), 14–22 (2000)

H.W. Lee, M.S.H. Chu, H.Y. Lu, J. Am. Ceram. Soc. 94(5), 1556–1562 (2011)

K. Morita, Y. Mizuno, H. Chazono, Jpn. J. Appl. Phys. 46(5R), 2984 (2007)

J.K. Lee, K.S. Hong, J.W. Jang, J. Am. Ceram. Soc. 84(9), 2001–2006 (2001)

M.B. Smith, K. Page, T. Siegrist, P.L. Redmond, E.C. Walter, R. Seshadri, L.E. Brus, M.L. Steigerwald, J. Am. Ceram. Soc. 130(22), 6955–6963 (2008)

M.A. Mahdi, S.R. Yousefi, L.S. Jasim, Int. J. Hydrogen. Energy 47(31), 14319–14330 (2022)

S.R. Yousefi, M. Ghanbari, O. Amiri, J. Am. Ceram. Soc. 1, 1 (2021)

L.E. Cross, Ferroelectrics 76(1), 241–267 (1987)

Y. Slimani, B. Unal, E. Hannachi, Ceram. Int. 45(9), 11989–12000 (2019)

T. Tsurumi, M. Shono, H. Kakemoto, S. Wada, K. Saito, H. Chazono, J. Electroceram. 21(1), 17–21 (2008)

I.A. Santos, J.A. Eiras, J. Phys-Condens. Mat. 13(50), 11733 (2001)

D. Damjanovic, Rep. Prog. Phys. 61(9), 1267–1324 (1998)

Y.L. Li, L.E. Cross, L.Q. Chen, J. Appl. Phys. 98(6), 064101 (2005)

Y.B. Kil, K. Nagatoh, H. Kakemoto, S. Wada, S. Takahashi, J. Am. Ceram. Soc. 85(8), 1993–1996 (2002)

I. Fujii, M. Ugorek, S. Trolier-McKinstry, J. Appl. Phys. 107(10), 104116 (2010)

I. Fujii, S. Trolier-McKinstry, C. Nies, J. Am. Ceram. Soc. 94(1), 58–63 (2011)

S.H. Yoon, J. Am. Ceram. Soc. 101, 1544–1553 (2018)

M. Nagayoshi, K. Matsubara, N. Fujikawa, Jpn. J. Appl. Phys. 59, SPPC01 (2020)

S.J. Almalki, S. Nadarajah, Reliab. Eng. Syst. Saf. 124, 32–55 (2014)

H. Chazono, J. Appl. Phys. 40, 5624 (2001)

Funding

This study was supported by the National Key Research Program of China (Grant No. 2022YFB3807403), Natural Science Foundation of Guangdong Province (Grant No. 2022A1515012604), Foundation of State Key Laboratory of New Electronic Components and Materials (Grant No. FHR-JS-202011012), and Joint Innovation Center of Advanced Electronic Components and Materials (Grant No. FHR-JS-202103001).

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation, data collection, and analysis were performed by XH, PW, DB, and KL. Characterization and related discussion were performed by XH, PW and LK. Modified and reviewed the paper were performed by GJ and QW. Funding acquisition and Project administration were performed by LZ, RS, XC and ZF. The fifirst draft of the manuscript was written by XH and all authors commented on previous versions of the manuscript. All authors read and approved the fifinal manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors have no relevant financial or non-financial interests to disclose.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Huang, X., Wang, P., Zhang, L. et al. Enhanced reliability of ultra-thin multilayer ceramic capacitors (MLCCs) based on re-oxidation process. J Mater Sci: Mater Electron 34, 1463 (2023). https://doi.org/10.1007/s10854-023-10836-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10854-023-10836-6