Abstract

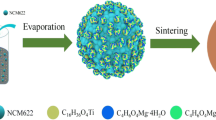

In spite of the advantages of LiNi0.8Co0.1Mn0.1O2 (NCM811) cathode materials such as high energy density and high capacity, their capacity decay during cycling is still a significant problem, which are mainly due to the internal structural collapse and the surge in interfacial impedance caused by interfacial side reactions. To address these issues, wet chemical methods and annealing treatments were used to create LiV2O4-coated and V4+-doped NCM811 cathode materials. The LiV2O4 coating layer and the doped V4+ had little effect on the crystal structure of the NCM811, according to X-ray powder diffraction and Rietveld refinement studies. Scanning electron microscopy, energy dispersive spectroscopy, X-ray photoelectron spectroscopy, and transmission electron microscopy data all showed that the LiV2O4 layer was successfully coated on the surface of the spherical particles and some of the V4+ was successfully introduced into the bulk phase. Thanks to the ion-conducting layer, LiV2O4, the interfacial impedance was reduced while the Li+ diffusion rate was accelerated, and the V4+ doped into the bulk phase stabilizes the internal structure, significantly increasing the cycling stability and the rate performance of NCM811. In particular, when the coating amount was 0.6 wt%, the initial discharge specific capacity reached 203.5 mAh/g at 2.8–4.3 V at 0.1 C, and the retention rate was 87.6% after 100 cycles, which was 12.1% higher compared to 75.5% of the original sample. And when the rate was raised to 5 C, the original sample’s capacity plummeted to only about 100 mAh/g, but the sample with 0.6 wt% of coating was still 140.9 mAh/g. Experiments confirmed that this LiV2O4 coating modification with synergistic V4+ doping provided an innovative technique for boosting the electrochemical performance of Ni-rich ternary cathode materials.

Similar content being viewed by others

Data availability

The datasets obtained during the current study are available from the corresponding authors upon reasonable request.

References

S. Choi, G.X. Wang, Adv. Mater. Technol. (2018). https://doi.org/10.1002/admt.201700376

F.F. Cao, Y.G. Guo, L.J. Wan, Energy Environ. Sci. 4, 1634 (2011). https://doi.org/10.1039/c0ee00583e

T. Ohzuku, R.J. Brodd, J. Power Sources. 174, 449 (2007). https://doi.org/10.1016/j.jpowsour.2007.06.154

T. Placke, R. Kloepsch, S. Duhnen, M. Winter, J. Solid State Electrochem. 21, 1939 (2017). https://doi.org/10.1007/s10008-017-3610-7

A. Ritchie, W. Howard, J. Power Sources. 162, 809 (2006). https://doi.org/10.1016/j.jpowsour.2005.07.014

B. Zhu, Z. Yu, L. Meng, Z. Xu, C. Lv, Y. Wang, G. Wei, J. Qu, Ionics. 27, 2749 (2021). https://doi.org/10.1007/s11581-021-04019-8

X. Tan, M. Zhang, J. Li, D. Zhang, Y. Yan, Z. Li, Ceram. Int. 46, 21888 (2020). https://doi.org/10.1016/j.ceramint.2020.06.091

Z. Feng, D. Sun, Y. Tang, H. Wang, Prog. Chem. 31, 442 (2019). https://doi.org/10.7536/pc180714

Y. Gao, X. Wang, J. Geng, F. Liang, M. Chen, Z. Zou, J. Electron. Mater. (2022). https://doi.org/10.1007/s11664-022-09978-w

S.K. Jung, H. Gwon, J. Hong, K.Y. Park, D.H. Seo, H. Kim, J. Hyun, W. Yang, K. Kang, Adv. Energy Mater. (2014). https://doi.org/10.1002/aenm.201300787

Y. Ding, B. Deng, H. Wang, X. Li, T. Chen, X. Yan, Q. Wan, M. Qu, G. Peng, J. Alloys Compd. 774, 451 (2019). https://doi.org/10.1016/j.jallcom.2018.09.286

X. Bai, L. Ban, W. Zhuang, J. Inorg. Mater. 35, 972 (2020). https://doi.org/10.15541/jim20190568

F.T. Geldasa, M.A. Kebede, M.W. Shura, F.G. Hone, RSC Adv. 12, 5891 (2022). https://doi.org/10.1039/d1ra08401a

J. Li, L.E. Downie, L. Ma, W.D. Qiu, J.R. Dahn, J. Electrochem. Soc. 162, A1401 (2015). https://doi.org/10.1149/2.1011507jes

Y. Makimura, S. Zheng, Y. Ikuhara, Y. Ukyo, J. Electrochem. Soc. 159, A1070 (2012). https://doi.org/10.1149/2.073207jes

S. Watanabe, M. Kinoshita, T. Hosokawa, K. Morigaki, K. Nakura, J. Power Sources. 258, 210 (2014). https://doi.org/10.1016/j.jpowsour.2014.02.018

Y. Chen, M. Wang, J. Chen, J. Yang, Z. Li, Y. Huang, Z. Chen, Y. Zou, J. Zheng, X. Li, Mater. Lett. (2020). https://doi.org/10.1016/j.matlet.2020.127771

L.T. Dou, P. Hu, C.Q. Shang, H. Wang, D.D. Xiao, U. Ahuja, K. Aifantis, Z.H. Zhang, Z.L. Huang, Chemelectrochem. 8, 4321 (2021). https://doi.org/10.1002/celc.202101230

L.Z. You, Y. Wen, G.X. Li, B.B. Chu, J.H. Wu, T. Huang, A.S. Yu, J. Mater. Chem. A 10, 5631 (2022). https://doi.org/10.1039/d2ta00135g

H.B. Kim, B.C. Park, S.T. Myung, K. Amine, J. Prakash, Y.K. Sun, J. Power Sources. 179, 347 (2008). https://doi.org/10.1016/j.jpowsour.2007.12.109

S. Ma, X. Zhang, S. Li, Y. Cui, Y. Cui, Y. Zhao, Y. Cui, Ionics. 26, 2165 (2020). https://doi.org/10.1007/s11581-019-03353-2

S. Dai, G. Yan, L. Wang, L. Luo, Y. Li, Y. Yang, H. Liu, Y. Liu, M. Yuan, J. Electroanal. Chem. (2019). https://doi.org/10.1016/j.jelechem.2019.113197

L.-J. Chang, S.-Y. Cao, S.-H. Luo, K. Li, X.-L. Bi, A.-L. Wei, J.-N. Liu, Energy Technol. (2021). https://doi.org/10.1002/ente.202100637

X. Feng, J. Zhang, L. Yin, Powder Technol. 287, 77 (2016). https://doi.org/10.1016/j.powtec.2015.09.031

S. Zhao, Y. Bai, L. Ding, B. Wang, W. Zhang, Solid State Ion. 247, 22 (2013). https://doi.org/10.1016/j.ssi.2013.05.022

B. Zhang, P. Dong, H. Tong, Y. Yao, J. Zheng, W. Yu, J. Zhang, D. Chu, J. Alloys Compd. 706, 198 (2017). https://doi.org/10.1016/j.jallcom.2017.02.224

Z. Chen, Z.L. Wang, G.T. Kim, G. Yang, H.H. Wang, X.S. Wang, Y.Z. Huang, S. Passerini, Z.X. Shen, ACS Appl. Mater. Interfaces. 11, 26994 (2019). https://doi.org/10.1021/acsami.9b08591

Y.H. Chen, J. Zhang, Y. Li, Y.F. Zhang, S.P. Huang, W. Lin, W.K. Chen, PCCP. 23, 11528 (2021). https://doi.org/10.1039/d1cp00426c

Y. Lu, X. Zeng, J. Wang, L. Yang, S. Hu, C. Jia, H. Zhao, D. Yin, X. Ge, X. Xi, Adv. Mater. Interfaces (2019). https://doi.org/10.1002/admi.201901368

M. Jo, M. Noh, P. Oh, Y. Kim, J. Cho, Adv. Energy Mater. (2014). https://doi.org/10.1002/aenm.201301583

Y.Q. Wang, Z.Z. Yang, Y.M. Qian, L. Gu, H.S. Zhou, Adv. Mater. 27, 3915 (2015). https://doi.org/10.1002/adma.201500956

X. Lai, G. Hu, Z. Peng, H. Tong, Y. Lu, Y. Wang, X. Qi, Z. Xue, Y. Huang, K. Du, Y. Cao, J. Power Sources. 431, 144 (2019). https://doi.org/10.1016/j.jpowsour.2019.05.044

A.M. Andersson, D.P. Abraham, R. Haasch, S. MacLaren, J. Liu, K. Amine, J. Electrochem. Soc. 149, A1358 (2002). https://doi.org/10.1149/1.1505636

W. Liu, X. Li, D. Xiong, Y. Hao, J. Li, H. Kou, B. Yan, D. Li, S. Lu, A. Koo, K. Adair, X. Sun, Nano Energy. 44, 111 (2018). https://doi.org/10.1016/j.nanoen.2017.11.010

W. Xiang, C.-Q. Zhu, J. Zhang, H. Shi, Y.-T. Liang, M.-H. Yu, X.-M. Zhu, F.-R. He, G.-P. Lv, X.-D. Guo, J. Alloys Compd. 786, 56 (2019). https://doi.org/10.1016/j.jallcom.2019.01.264

L.-. Li, Z.-X. Wang, Q.-C. Liu, C. Ye, Z.-Y. Chen, L. Gong, Electrochim. Acta. 77, 89 (2012). https://doi.org/10.1016/j.electacta.2012.05.076

Q. Fu, F. Du, X. Bian, Y. Wang, X. Yan, Y. Zhang, K. Zhu, G. Chen, C. Wang, Y. Wei, J. Mater. Chem. A 2, 7555 (2014). https://doi.org/10.1039/c4ta00189c

H. Wang, D.M. Sun, X. Li, W.J. Ge, B.W. Deng, M.Z. Qu, G.C. Peng, Electrochim. Acta. 254, 112 (2017). https://doi.org/10.1016/j.electacta.2017.09.111

J. Fu, D. Mu, B. Wu, J. Bi, X. Liu, Y. Peng, Y. Li, F. Wu, Electrochim. Acta. 246, 27 (2017). https://doi.org/10.1016/j.electacta.2017.06.038

H.-J. Noh, S. Youn, C.S. Yoon, Y.-K. Sun, J. Power Sources. 233, 121 (2013). https://doi.org/10.1016/j.jpowsour.2013.01.063

D.D. MacNeil, Z. Lu, J.R. Dahn, J. Electrochem. Soc. 149, A1332 (2002). https://doi.org/10.1149/1.1505633

S.H. Kang, D.P. Abraham, W.S. Yoon, K.W. Nam, X.Q. Yang, Electrochim. Acta. 54, 684 (2008). https://doi.org/10.1016/j.electacta.2008.07.007

J.-Z. Kong, S.-S. Wang, G.-A. Tai, L. Zhu, L.-G. Wang, H.-F. Zhai, D. Wu, A.-D. Li, H. Li, J. Alloys Compd. 657, 593 (2016). https://doi.org/10.1016/j.jallcom.2015.10.187

X. Li, K. Zhang, D. Mitlin, Z. Yang, M. Wang, Y. Tang, F. Jiang, Y. Du, J. Zheng, Chem. Mater. 30, 2566 (2018). https://doi.org/10.1021/acs.chemmater.7b04861

L. Depicciotto, Solid State Ion. 28, 1364 (1988)

Acknowledgements

The authors are grateful the support from the National Natural Science Foundation of China (No. 51562006 and No. 52162038) and the Guangxi Distinguished Experts Special Fund (No. 2019B06).

Funding

Funding was provided by the National Natural Science Foundation of China (No. 51562006 and No. 52162038) and the Special Fund for Distinguished Experts in Guangxi of China (No. 2019B06).

Author information

Authors and Affiliations

Contributions

Each author contributed to this study. Experimental manipulations were performed by YG and XW, while JG, MC, and FY for data collection and analysis. The first draft of the manuscript was written by YG, and ZZ reviewed previous versions of the manuscript and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors have no relevant financial or non-financial interests to disclose.

Ethical approval

The authors declare this article does not involve research with humans or animals.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Gao, Y., Wang, X., Zou, Z. et al. Enhanced electrochemical performance of LiV2O4-coated and V4+-doped LiNi0.8Co0.1Mn0.1O2 cathode for lithium-ion batteries. J Mater Sci: Mater Electron 34, 1448 (2023). https://doi.org/10.1007/s10854-023-10798-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10854-023-10798-9