Abstract

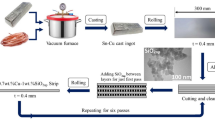

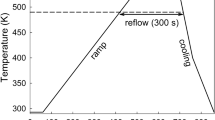

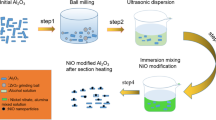

This study synthesized Sn-0.7wt.%Cu/Xwt.%SiO2 nanocomposite solder by angular accumulative extrusion (AAE). AAE is a severe plastic deformation process used here to synthesize a metal matrix composite for the first time. The Sn-0.7wt.%Cu lead-free solder has proved to be an appropriate alternative for Sn–Pb solder due to its lower cost than other lead-free solders, good wetting and electrical conductivity, and high creep resistance. The characterization results showed that adding silica nanoparticles improved the solder properties compared to the monolithic sample. Compared to the monolithic sample, the tensile properties of as-extruded nanocomposite solder samples containing 0.5- and 1-wt% nanoparticles have increased by 22 and 12%, respectively. The joint shear strength of nanocomposite solders increased by 9% and 17%, tensile strength by 41% and 44% and microhardness by 14% and 32% after reflow for the samples containing 0.5 and 1% nanoparticles, compared to the monolithic sample, respectively. Moreover, adding nanosilica particles decreased the wetting angle with a copper substrate, refined the microstructure, and suppressed undesired intermetallic compound formation compared to the monolithic sample. Accordingly, the synthesis of nanocomposite solder by AAE has been successful.

Similar content being viewed by others

Data availability

The data supporting the findings of this study are available within the paper.

References

H. Ma, J.C. Suhling, A review of mechanical properties of lead-free solders for electronic packaging. J. Mater. Sci. 44(5), 1141–1158 (2009)

X. Zeng, X. Huo, X. Xu, D. Liu, E-waste lead exposure and children’s health in China. Sci. Total Environ. 734, 139286 (2020)

M. Abtew, G. Selvaduray, Lead-free solders in microelectronics. Mater. Sci. Engineering: R: Rep. 27(5–6), 95–141 (2000)

H.R. Kotadia, P.D. Howes, S.H. Mannan, A review: on the development of low melting temperature Pb-free solders. Microelectron. Reliab. 54(6–7), 1253–1273 (2014)

J.S. Hwang, Implementing lead-free Electronics (McGraw-Hill Professional Engin, 2005)

E.E.M. Noor, A. Singh, Y.T. Chuan, A Review: Influence of nano Particles Reinforced on Solder Alloy (Soldering & Surface Mount Technology, 2013)

P. Zhang, S. Xue, J. wang, P. Xue, S. Zhong, W. Long, Effect of nanoparticles addition on the microstructure and properties of lead-free solders: a review Applied Sciences, 2019. 9(10): p. 2044

M. Hosseini, B. Niroumand, A. Maleki, H.K. Issa, Manufacturing and characterization of Sn–Cu/SiO2nplead-free nanocomposite solder by accumulative roll bonding (ARB) process. J. Mater. Sci.: Mater. Electron., 2022: p. 1–15

Z. Fathian, A. Maleki, B. Niroumand, Synthesis and characterization of ceramic nanoparticles reinforced lead-free solder. Ceram. Int. 43(6), 5302–5310 (2017)

A. Roshanghias, A.H. Kokabi, Y. Miyashita, Ceria reinforced nanocomposite solder foils fabricated by accumulative roll bonding process. J. Mater. Sci.: Mater. Electron. 23(9), 1698–1704 (2012)

M.A.A. Mohd Salleh, A.M. Mustafa Al Bakri, M.H. Zan, F. Somidin, Farhani Mohd Alui, Z. Arifin Ahmad, Mechanical properties of Sn–0.7Cu/Si3N4 lead-free composite solder. Mater. Sci. Engineering: A 556, 633–637 (2012)

X. Zhong, M. Gupta, Development of lead-free Sn–0.7 Cu/Al2O3 nanocomposite solders with superior strength. J. Phys. D 41(9), 095403 (2008)

L.C. Tsao, C.H. Huang, C.H. Chung, R.S. Chen, Influence of TiO2 nanoparticles addition on the microstructural and mechanical properties of Sn-0.7Cu nanocomposite solder. Mater. Sci. Engineering: A 545, 194–200 (2012)

H. Khanlari, M. Honarpisheh, Investigation of microstructure, mechanical properties and residual stress in non-equal-channel angular pressing of 6061 aluminum alloy. Trans. Indian Inst. Met. 73(5), 1109–1121 (2020)

M. Senemar, A. Maleki, B. Niroomand, A.R. Allafchian, A novel and facile method for silica nanoparticles synthesis from high temperature vulcanization (HTV) silicon. Metall. Mater. Eng. 22(1), 1–8 (2016)

A. Abd El-Rehim, H. Zahran, A. Yassin, Microstructure evolution and tensile creep behavior of Sn–0.7Cu lead-free solder reinforced with ZnO nanoparticles. J. Mater. Sci.: Mater. Electron. 30(3), 2213–2223 (2019)

M. Gussev, J.T. Busby, K.G. Field, M.A. Skolov, S.E. Gray, Role of scale factor during tensile testing of small specimens, in Small Specimen Test Techniques: 6th Volume. 2015, ASTM International

L. Wang, D.Q. Yu, S.Q. Han, H.T. Ma, H.P. Xie, The evaluation of the new composite lead free solders with the novel fabricating process. in Proceedings of 2004 International Conference on the Business of Electronic Product Reliability and Liability (IEEE Cat. No. 04EX809). 2004. IEEE

J. Cugnoni, J. Botsis, V. Sivasubramaniam, J. Janczak-rusch, Experimental and numerical studies on size and constraining effects in lead-free solder joints. Fatigue. Fract. Eng. Mater. Struct. 30(5), 387–399 (2007)

A. Standard, E384, Standard test Method for Microindentation Hardness of Materials (ASTM International, West Conshohocken, PA, 2000)

M. Senemar, B. Niroumand, A. Maleki, P.K. Rohatgi, Synthesis of the in situ aluminum matrix composite through pyrolysis of high temperature vulcanization silicone. J. Compos. Mater. 52(1), 123–134 (2018)

L. Zhang, K.N. Tu, Structure and properties of lead-free solders bearing micro and nano particles. Mater. Sci. Engineering: R: Rep. 82, 1–32 (2014)

A. Yakymovych, Y. Plevachuk, P. Švec Sr, P. Švec, D. Janičkovič, P. Šebo, N. Beronská, A. Roshanghias, H. Ipser, Morphology and shear strength of lead-free solder joints with Sn3.0Ag0.5Cu solder paste reinforced with ceramic nanoparticles. J. Electron. Mater. 45(12), 6143–6149 (2016)

A.K. Gain, Y.C. Chan, W.K. Yung, Effect of additions of ZrO2 nanoparticles on the microstructure and shear strength of Sn–Ag–Cu solder on Au/Ni metallized Cu pads. Microelectron. Reliab. 51(12), 2306–2313 (2011)

Y. Wang, X. Zhao, X. Xie, Y. Gu, Y. Liu, Effects of nano-SiO2 particles addition on the microstructure, wettability, joint shear force and the interfacial IMC growth of Sn3.0Ag0.5Cu solder. J. Mater. Sci.: Mater. Electron. 26(12), 9387–9395 (2015)

Y. Tang, Q.W. Guo, S.M. Luo, Z.H. Li, G.Y. Li, C.J. Hou, Z.Y. Zhong, J.J. Zhuang, Formation and growth of interfacial intermetallics in Sn-0.3Ag-0.7Cu-xCeO2/Cu solder joints during the reflow process. J. Alloys Comp, 2019. 778: p. 741–755

M.A.A. Mohd Salleh, S.D. McDonald, C.M. Gourlay, H. Yasuda, K. Nogita, Suppression of Cu6Sn5 in TiO2 reinforced solder joints after multiple reflow cycles. Mater. Design. 108, 418–428 (2016)

L. Yang, Z. Zhang, Effects of Y2O3 nanoparticles on growth behaviors of Cu6Sn5 grains in soldering reaction. J. Electron. Mater. 42(12), 3552–3558 (2013)

E.E.M. Noor, N.F.M. Nasir, S.R.A. Idris, A Review: Lead free Solder and its Wettability Properties (Soldering & Surface Mount Technology, 2016)

Acknowledgements

The Iran National Science Foundation (INSF) has supported this research, conducted at the Isfahan University of Technology.

Author information

Authors and Affiliations

Contributions

Ali Karimi implemented the experimental procedure and prepared the manuscript draft. Ali Maleki supervised the research and corrected the manuscript. Aboozar Taherizadeh and Behzad Niroumand were the advisors of the research and proof read the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The author declared that there is no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Karimi, A., Maleki, A., Taherizadeh, A. et al. Synthesis and characterization of Sn–Cu/SiO2(np) lead-free nanocomposite solder through angular accumulative extrusion. J Mater Sci: Mater Electron 34, 1455 (2023). https://doi.org/10.1007/s10854-023-10783-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10854-023-10783-2