Abstract

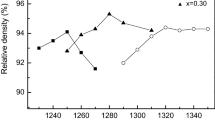

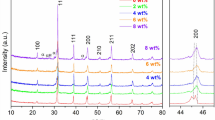

The cost-effective solid-state reaction technique has been used for the synthesis of an environment-friendly Ba1−xCax(Mg1/3Nb2/3)O3 (BCMN) ceramics for x = 0%, 5%, 10%, 15%, 20% to examine thoroughly its structural, morphological, and electrical behavior with raising calcium content. We aim to describe in this article how lead-free dielectrics can provide a path to a more ecologically friendly option in this remarkable material class. The XRD patterns reveal the ceramic to be a hexagonal structure with space group P-3m1, no. 164. An essential set of properties, dielectric and AC impedance, has been examined as a function of frequency and temperature along with room-temperature ferroelectric properties of the ceramics. Temperature-dependent conductivity and activation energy have been performed with an increasing calcium content to understand the role of calcium in BMN ceramics. The results show that dielectric properties can be affected by different calcium concentrations. These dielectrics can work satisfactorily and attain a very high temperature of up to 600 °C. Energy storage with long-term reliability is needed to ensure that capacitors do not need to be oversized. This article provides ultrahigh energy storage efficiency and low loss at room temperature. The highest storage efficiency η% that has been found in these compositions is for 15%; Ca-containing composition is 97.68%. The enhanced dielectric properties along with reduced energy loss have made BCMN a prominent energy storage material.

Similar content being viewed by others

Data availability

In addition to the information presented in the manuscript, additional data could be made available to the readers at reasonable request.

References

L. Tan, Q. Sun, Y. Wang, J. Alloys Compd. 836, 155419 (2020). https://doi.org/10.1016/j.jallcom.2020.155419

X. Wang, C. Meng, Y. Wang, Ceram. Int. 47(20), 28500–28504 (2021). https://doi.org/10.1016/j.ceramint.2021.07.006

X. Huang, G. Zhao, G. Wang, J.T.S. Irvine, Chem. Sci. 9(15), 3623–3637 (2018). https://doi.org/10.1039/C7SC03920D

X.-Q. Song, Lu. Wen-Zhong, X.-C. Wang, X.-H. Wang, G.-F. Fan, R. Muhammad, W. Lei, J. Eur. Ceram. Soc. 38(4), 1529–1534 (2018). https://doi.org/10.1016/j.jeurceramsoc.2017.10.053

F. Galasso, L. Katz, R. Ward, J. Am. Chem. Soc. 81(4), 820–823 (1959). https://doi.org/10.1021/ja01513a018

F. Galasso, J. Pyle, Inorg. Chem. 2(3), 482–484 (1963). https://doi.org/10.1021/ic50007a013

L.A. Khalam, H. Sreemoolanathan, R. Ratheesh, P. Mohanan, M.T. Sebastian, Mater. Sci. Eng. 107(3), 264–270 (2004) https://doi.org/10.1016/j.mseb.2003.11.019

J. Li, J. Lv, S. Feng, Z.-M. Qi, R. Han, J. Wang, Mater. Res. Bull. 148, 111656 (2022). https://doi.org/10.1016/j.materresbull.2021.111656

H.-F. Cheng, C.-T. Chia, H.-L. Liu, M.-Y. Chen, Y.-T. Tzeng, I-N. Lin, J. Eur. Ceram. Soc. 27(8–9), 2893–2897 (2007). https://doi.org/10.1016/j.jeurceramsoc.2006.11.067

B.C. Sekhar, B. Dhanalakshmi, B. Srinivasa Rao, S. Ramesh, K. Venkata Prasad, P.S.V. Subba Rao, B. Parvatheeswara Rao, Multifunct. Ferroelectric Mater. (2021). https://doi.org/10.5772/intechopen.96154

D. Choudhury, A. Venimadhav, C. Kakarla, K.T. Delaney, P. Sujatha Devi, P. Mondal, R. Nirmala, et al. Appl. Phys. Lett. 96(16), 162903 (2010). https://doi.org/10.1063/1.3379293

Z. Tang, Z. Zhou, Z. Zhang, Sens. Actuators B Chem. 93(1–3), 391–395 (2003). https://doi.org/10.1016/S0925-4005(03)00197-7

P. Zhang, H. Li, X. Chen, Q. Wen, C. Li, J. Eur. Ceram. Soc. 41(16), 165–170 (2021). https://doi.org/10.1016/j.jeurceramsoc.2021.09.015

M.T. Sebastian, Elsevier (2010)

M.W. Lufaso, Chem. Mater. 16(11), 2148–2156 (2004). https://doi.org/10.1021/cm049831k

R.L. Moreira, F.M. Matinaga, A. Dias, Appl. Phys. Lett. 78(4), 428–430 (2001). https://doi.org/10.1063/1.1339254

A. Dias, V.S.T. Ciminelli, F.M. Matinaga, R.L. Moreira, J. Eur. Ceram. Soc. 21(15), 2739–2744 (2001). https://doi.org/10.1016/S0955-2219(01)00355-7

A. Dias, R.L. Moreira, J. Appl. Phys. 94(5), 3414–3421 (2003). https://doi.org/10.1063/1.1598634

A. Dias, C.W.A. Paschoal, R.L. Moreira, J. Am. Ceram. Soc. 86(11), 1985–1987 (2003). https://doi.org/10.1111/j.1151-2916.2003.tb03597.x

F. Mou, An. Xue, Q. Liu, S. Peng, Y. Wang, E. Cai, S. Wang, J. Mater. Sci.: Mater. Electron. 32(2), 2432–2440 (2021). https://doi.org/10.1007/s10854-020-05009-8

An. Xue, F. Zeng, Y. Wang, Q. Liu, X. Wang, S. Peng, F. Mou, J. Mater. Sci.: Mater. Electron. 31(11), 8291–8296 (2020). https://doi.org/10.1007/s10854-020-03364-0

F. Zeng, Q. Liu, Y. Wang, S. Peng, An. Xue, E. Cai, J. Mater. Sci.: Mater. Electron. 29(22), 18978–18988 (2018). https://doi.org/10.1007/s10854-018-0022-0

F. Zeng, Q. Liu, S. Peng, Y. Wang, E. Cai, An. Xue, S. Zhou, Ceram. Int. 45(1), 1416–1419 (2019). https://doi.org/10.1016/j.ceramint.2018.09.185

J. Boonlakhorn, J. Prachamon, J. Manyam, S. Krongsuk, P. Thongbai, P. Srepusharawoot, RSC Adv. 11(27), 16396–16403 (2021). https://doi.org/10.1039/D1RA02707G

H.J. Lee, M.P. Hyun, Y.K. Cho, H. Ryu, Y.W. Song, J.H. Paik, S. Nahm, J.‐D. Byun, J. Am. Ceram. Soc. 83(9), 2267–2272 (2000). https://doi.org/10.1111/j.1151-2916.2000.tb01546.x

H. Lin, Xu. Dekang, Lu. Anming Li, Z.Q. Yao, S. Yang, Y. Zhang, Sci. Rep. 7(1), 1–11 (2017). https://doi.org/10.1038/s41598-017-14228-9

R. Stephenson, J. Cockcroft, R. Cernik, D. Watkin, L.M.D. Cranswick, Acta Crystallogr. Sect. A Found. Crystallogr. 60(a1), s233–s233 (2004). https://doi.org/10.1107/S0108767304095388

C.-L. Diao, C.-H. Wang, N.-N. Luo, Z.-M. Qi, T. Shao, Y.-Y. Wang, J. Lu, F. Shi, X.‐P. Jing, J. Appl. Phys. 115 (11), 114103 (2014). https://doi.org/10.1063/1.4868226

M. Rahimian, N. Ehsani, N. Parvin, H.R. Baharvandi, J. Mater. Process. Technol. 209(14), 5387–5393 (2009). https://doi.org/10.1016/j.jmatprotec.2009.04.007

S.E. Etuk, S.S. Ekpo, U.W. Robert, O.E. Agbasi, E.-A.A. Effiong, Acta Tech. Jaurinensis 15(2), 91–98 (2022). https://doi.org/10.14513/actatechjaur.00648

R. Tang, C. Jiang, W. Qian, J. Jian, X. Zhang, H. Wang, H. Yang, Sci Rep 5, 13645 (2015). https://doi.org/10.1038/srep13645

A. Moliton, Applied Electromagnetism and Materials (Springer, Cham, 2007). https://doi.org/10.1007/978-0-387-38064-3

W.H. Tzing, W.H. Tuana, H.L. Lin, Ceram. Int. 25, 425–430 (1999). https://doi.org/10.1016/S0272-8842(98)00058-3

P. Nayak, T. Badapanda, A.K. Singh, S. Panigrahi, RSC Adv. 7(27), 16319–16331 (2017). https://doi.org/10.1039/C7RA00366H

G.-F. Zhang, H. Liu, Z. Yao, M. Cao, H. Hao, J. Mater. Sci. Mater. Electron. 26, 2726–2732 (2015). https://doi.org/10.1007/s10854-015-2749-1

S. Sen, R.N.P. Choudhary, Mater. Chem. Phys. 87(2–3), 256–263 (2004). https://doi.org/10.1016/j.matchemphys.2004.03.005

P.G.R. Achary, S. Behera, R.N.P. Choudhary, S.K. Parida, J. Mater. Sci.: Mater. Electron. 32, 5738–5754 (2021). https://doi.org/10.1007/s10854-021-05295-w

D.C. Sinclair, A.R. West, J. Appl. Phys. 66(8), 3850–3856 (1989). https://doi.org/10.1063/1.344049

K. Srinivas, A.R. James, J. Appl. Phys. 86(7), 3885–3889 (1999). https://doi.org/10.1063/1.371304

K.J. Hamam, F. Salman, Appl. Phys. A 125, 621 (2019). https://doi.org/10.1007/s00339-019-2868-2

Y.-L. Pei, J. He, Fu. Jing-Feng Li, Q.L. Li, W. Pan, C. Barreteau, D. Berardan, N. Dragoe, L.-D. Zhao, NPG Asia Mater. 5(5), e47–e47 (2013). https://doi.org/10.1038/am.2013.15

B.K. Sonu, E. Sinha, J. Alloys Compd. 860, 158471 (2021). https://doi.org/10.1016/j.jallcom.2020.158471

G. Hu, J. Wang, X. Liu, H. Liu, H. Wang, Xu. Jiwen, L. Yang, C. Zhou, W. Qiu, J. Mater. Sci.: Mater. Electron. 32(17), 22300–22308 (2021). https://doi.org/10.1007/s10854-021-06715-7

D.K. Kushvaha, B. Tiwari, S.K. Rout, J. Alloys Compd. 829, 154573 (2020). https://doi.org/10.1016/j.jallcom.2020.154573

X. Li, D. Xiaoyan, W. Fei, T. Zhi, Z. Qiming, C. Hao, X.J. Xing, J.Z. Huanfu, J. Zhu, J. Eur. Ceram. Soc. (2022). https://doi.org/10.1016/j.jeurceramsoc.2021.12.028

Funding

Naincy Kumari acknowledges the financial support from Birla Institute of Technology, Mesra, as an institute research fellow (IRF).

Author information

Authors and Affiliations

Contributions

NK prepared the materials, collected the data, and conducted the analysis. SKR provided overall guidance and concept development.

Corresponding author

Ethics declarations

Competing interests

There are no relevant financial or non-financial interests to disclose for the authors.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kumari, N., Rout, S.K. Structural and electrical properties of Ca2+-substituted barium magnesium niobate ceramics. J Mater Sci: Mater Electron 34, 205 (2023). https://doi.org/10.1007/s10854-022-09644-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10854-022-09644-1