Abstract

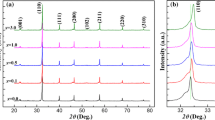

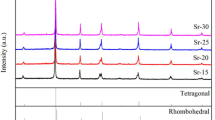

The tungsten bronze ceramics were prepared by solid-state reaction method to investigate the effect of La3+ concentration on the microstructure, dielectric and ferroelectric properties of Sr4 − xNa2 − xLaxTa0.6Nb9.4O30 (SNLTN: 0 ≤ x ≤ 0.4). X-ray diffraction results show that the tungsten bronze phase structure was a tetragonal phase in the P4bm space group at room temperature. The A-site structural vacancies increases as the structure transformed from “filled” to “unfilled” state. At the same time, the distortion of the BO6 octahedral increases. The results of the temperature dependence of the dielectric constant indicate that adding La3+ promotes the emergence of dipole-glass-like behavior and enhances dielectric relaxation. To better understand how polar clusters in Sr4 − xNa2 − xLaxTa0.6Nb9.4O30 ceramics change with increasing x, the size and kinetic behavior of PNRs were calculated and analyzed using the Vogel-Fulcher relationship and macroscopic and phenomenological statistical model, which reveals that the thermal stability of the dielectric constant is inversely related to the size of PNRs in addition to the long-range ordering of the system is disrupted. Hence, it is critical for the energy storage performance to obtain small size and the high number of active PNRs and the weak coupling between PNRs and other polar clusters. Finally, an energy storage density of 2.06 J/cm3 was received in Sr3.8Na1.8La0.2Ta0.6Nb9.4O30.

Similar content being viewed by others

Data availability

The data that support the findings of this study are available in this paper and on a request from the corresponding author.

References

M. Said, T.S. Velayutham, W.C. Gan, W.H. Abd Majid, Ceram. Int. 41, 7119–7124 (2015). https://doi.org/10.1016/j.ceramint.2015.02.023

W. Chen, W.Z. Yang, X.Q. Liu, X.M. Chen, J. Alloys Compd. 675, 311–316 (2016). https://doi.org/10.1016/j.jallcom.2016.03.099

P. Yang, L. Li, S. Hao, X. Chao, L. Wei, Z. Yang, J. Eur. Ceram. Soc. 37, 2605–2613 (2017). https://doi.org/10.1016/j.jeurceramsoc.2017.02.035

M.P. Trubelja, E. Ryba, D.K. Smith, J. Mater. Sci. 31, 1435–1443 (1996). https://doi.org/10.1007/BF00357850

V. Veerapandiyan, F. Benes, T. Gindel, M. Deluca, Materials 13, 5742 (2020). https://doi.org/10.3390/ma13245742

Z. Yang, R. Gu, L. Wei, H. Ren, J. Alloys Compd. 504, 211–216 (2010). https://doi.org/10.1016/j.jallcom.2010.05.093

Y. Wang, T.L. Sun, X.L. Zhu, L. Liu, X.M. Chen, J. Appl. Phys. 129, 244107 (2021). https://doi.org/10.1063/5.0050391

M. Zhang, X. Zuo, J. Alloys Compd. 806, 386–392 (2019). https://doi.org/10.1016/j.jallcom.2019.07.269

S. Cao, J. Zhu, Q. Chen et al., J. Materiomics 8, 38–46 (2022). https://doi.org/10.1016/j.jmat.2021.06.001

S. Koohi-Fayegh, M.A. Rosen, J. Energy Storage 27, 101047 (2020). doi:https://doi.org/10.1016/j.est.2019.101047

L. Cao, Y. Yuan, X. Zhang, E. Li, S. Zhang, ACS Sustain. Chem. Eng. 8, 17527–17539 (2020). https://doi.org/10.1021/acssuschemeng.0c06861

H.L. Wang, X.Y. Bu, X.Z. Zhang et al., ACS Appl. Energy Mater. 4, 9066–9076 (2021). https://doi.org/10.1021/acsaem.1c01369

X. Zhang, W. Ye, X. Bu et al., Dalton Trans. 50, 124–130 (2021). https://doi.org/10.1039/d0dt03511d

S. Xu, R. Hao, Z. Yan et al., J. Eur. Ceram. Soc. 42, 2781–2788 (2022). https://doi.org/10.1016/j.jeurceramsoc.2022.02.005

X. Zhang, H. Wang, X. Bu et al., Inorg. Chem. 60, 6559–6568 (2021). https://doi.org/10.1021/acs.inorgchem.1c00362

E. García-González, A. Torres-Pardo, R. Jiménez, J.M. González-Calbet, Chem. Mater. 19, 3575–3580 (2007). https://doi.org/10.1021/cm071303w

X. Zhu, M. Fu, M.C. Stennett et al., Chem. Mater. 27, 3250–3261 (2015). https://doi.org/10.1021/acs.chemmater.5b00072

A. Torres-Pardo, R. Jiménez, J.M. González-Calbet, E. García-González, Inorg. Chem. 50, 12091–12098 (2011). https://doi.org/10.1021/ic2016098

W.H. Huang, D. Viehland, R.R. Neurgaonkar, J. Appl. Phys. 76, 490–496 (1994). https://doi.org/10.1063/1.357100

J. Gardner, F. Yu, C. Tang, W. Kockelmann, W. Zhou, F.D. Morrison, Chem. Mater. 28, 4616–4627 (2016). https://doi.org/10.1021/acs.chemmater.6b01306

P. Yang, B. Yang, S. Hao, L. Wei, Z. Yang, J. Alloys Compd. 685, 175–185 (2016). https://doi.org/10.1016/j.jallcom.2016.05.035

Z. Wu, S. Li, Y.M. Yousry et al., Nat. Commun. 13, 3104 (2022). https://doi.org/10.1038/s41467-022-30822-6

P.A. Fleury, Annu. Rev. Mater. Sci. 6, 157–180 (1976). https://doi.org/10.1146/annurev.ms.06.080176.001105

J. Liu, F. Li, Y. Zeng et al., Phys. Rev. B 96, 054115 (2017). doi:https://doi.org/10.1103/PhysRevB.96.054115

L. Liu, S. Ren, J. Zhang, B. Peng, L. Fang, D. Wang, J. Am. Ceram. Soc. 101, 2408–2416 (2018). https://doi.org/10.1111/jace.15410

M.J. Haun, E. Furman, S.J. Jang, L.E. Cross, Ferroelectrics 99, 63–86 (1989). doi:https://doi.org/10.1080/00150198908221440

L. Chen, S. Deng, H. Liu, J. Wu, H. Qi, J. Chen, Nat. Commun. 13, 3089 (2022). https://doi.org/10.1038/s41467-022-30821-7

D.J. Zhang, X. Yao, Acta Phys. Chim. Sin. 20, 712–716 (2004). https://doi.org/10.3866/pku.whxb20040709

K. Chen, F. Wei, L. Jia et al., J. Am. Ceram. Soc. 103, 2859–2867 (2019). https://doi.org/10.1111/jace.16956

T. Shao, H. Du, H. Ma et al., J. Mater. Chem. A 5, 554–563 (2017). doi:https://doi.org/10.1039/C6TA07803F

J. Ye, G. Wang, M. Zhou et al., J. Mater. Chem. C 7, 5639–5645 (2019). doi:https://doi.org/10.1039/C9TC01414D

P. Zhao, Z. Cai, L. Wu, C. Zhu, L. Li, X. Wang, J. Adv. Ceram. 10, 1153–1193 (2021). https://doi.org/10.1007/s40145-021-0516-8

K. Uchino, S. Nomura, Ferroelectrics 44, 55–61 (1982). doi:https://doi.org/10.1080/00150198208260644

D. Viehland, S.J. Jang, L.E. Cross, M. Wuttig, J. Appl. Phys. 68, 2916–2921 (1990). https://doi.org/10.1063/1.346425

W.B. Feng, X.L. Zhu, X.Q. Liu et al., J. Am. Ceram. Soc. 101, 1623–1631 (2018). https://doi.org/10.1111/jace.15332

H. Ogihara, C.A. Randall, S. Trolier-McKinstry, J. Am. Ceram. Soc. 92, 1719–1724 (2009). https://doi.org/10.1111/j.1551-2916.2009.03104.x

M. Zhou, R. Liang, Z. Zhou, X. Dong, J. Mater. Chem. C 6, 8528–8537 (2018). doi:https://doi.org/10.1039/c8tc03003k

N. Zhang, W. Gao, H. Zhang et al., Vib. Spectrosc. 58, 74–78 (2012). https://doi.org/10.1016/j.vibspec.2011.10.001

Y.B. Yao, C.L. Mak, B. Ploss, J. Eur. Ceram. Soc. 32, 4353–4361 (2012). https://doi.org/10.1016/j.jeurceramsoc.2012.07.034

L. Luisman, A. Feteira, K. Reichmann, Appl. Phys. Lett. 99, 192901 (2011). https://doi.org/10.1063/1.3660255

V. Bobnar, J. Holc, M. Hrovat, M. Kosec, J. Appl. Phys. 101, 074103 (2007). https://doi.org/10.1063/1.2717090

Funding

The authors thank the National Natural Science Foundation of China (12164012), Science and Technology Major Project of Guangxi (AA21077012), Natural Science Foundation of Guangxi (Nos. AA21238001, 2022ZYZX1173, GA245006, BA245069, BA297029, AD18281042), and open funding of the Key Laboratory of New Processing Technology for Nonferrous Metal & Materials, Ministry of Education/Guangxi Key Laboratory of Optical and Electronic Materials and Devices (19AA-15, 20KF-16) for financial support.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation, data collection and analysis were performed by XZ, ZJ and YD. The first draft of the manuscript was written by XZ, and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors have no relevant financial or non-financial interests to disclose.

Ethical approval

This article does not contain any studies with human participants or animals performed by any of the authors. In this manuscript, we did not collect any samples of human and animals.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zheng, X., Jin, Z., Dan, Y. et al. Relaxation behavior and energy storage of A-site substituted Sr4−xNa2−xLaxTa0.6Nb9.4O30 ferroelectric ceramics. J Mater Sci: Mater Electron 34, 148 (2023). https://doi.org/10.1007/s10854-022-09492-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10854-022-09492-z