Abstract

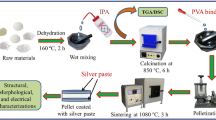

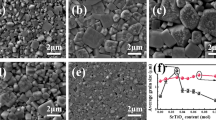

Lead-free KxNa1−xNbO3 (KNN) ceramics with x = 0.35–0.49 were successfully synthesized and systematically studied. The effects of the K/Na ratio on the electrical properties of the materials were also studied. The results revealed that the KNN ceramics with the K/Na ratio of 41/59 consisted of uniform particles with an average size of 2.21 μm. The particles were tightly packed and suitable for the fabrication of samples with the maximum ceramic density (ρ = 4.36 g/cm3) under conditions of varying compositional ratios. XRD patterns recorded for the KNN ceramics revealed the presence of the pure orthorhombic perovskite phase, in which the lattice parameters increase with an increase in the x value. This resulted in the monotonic shift toward the lower 2θ regions. Furthermore, the experimental results also showed that the KNN ceramic properties were further enhanced by adjusting the Na/K ratio of the A-site. The materials exhibited the best physical, dielectric, and ferroelectric properties (ε = 470, kp = 0.32, kt = 0.5, d33 = 120 pC/N, Pr = 11.6 µC/cm2) when the K/Na ratio was 41/59. In addition, the Wrec, η, Smax, and d33* values tended to increase with an increase in the x value. The maximum values of 0.464 J/cm3, 30.34%, 0.097%, and 241 pm/V, respectively, were recorded at a K/Na ratio of 45/55. Under these conditions, improved energy storage and converse piezoelectric properties could be realized for KNN ceramics.

Similar content being viewed by others

Data availability

The raw data supporting the conclusions of this article will be made available by the authors on reasonable request.

References

D.A. Quang, L.D. Vuong, J. Sci.: Adv. Mater. Devices 7(2), 100436 (2022)

L.D. Vuong, J. Mater. Sci.: Mater. Electron. 33(9), 6710–6721 (2022)

P.D. Gio, L.D. Vuong, V. ThanhTung, J. Electroceram 46(3), 107–114 (2021)

D.A. Tuan, V.T. Tung, L.D. Vuong, N.H. Yen, L.T.U. Tu, J. Electron. Mater. 47(10), 6297–6301 (2018)

D. Biswas, P. Sharma, N.S. Panwar, Ferroelectrics 571(1), 214–229 (2021)

K. Tanaka, K. Kakimoto, H. Ohsato, J. Eur. Ceram. Soc. 27(13–15), 3591–3595 (2007)

N. Chaiyo, R. Muanghlua, S. Niemcharoen, B. Boonchom, N. Vittayakorn, J. Alloys Compd. 509(5), 2445–2449 (2011)

F. Yu, P. Wang, J. Lin, P. Zhou, Y. Ma, X. Wu, C. Lin, C. Zhao, M. Gao, Q. Zhang, J. Lumin. 252, 119345 (2022)

D. Zhang, Z. Zhang, 2015 Joint IEEE International Symposium on the Applications of Ferroelectric (ISAF), International Symposium on Integrated Functionalities (ISIF), and Piezoelectric Force Microscopy Workshop (PFM) (2015), pp. 237–239

P.D. Gio, L.D. Vuong, L.T.U. Tu, J. Mater. Sci.: Mater. Electron. 32(10), 13738–13747 (2021)

J. Chen, W. Wu, S. Su, J. Yu, X. Lei, P. Zhao, J. Wuhan Univ. Technol. Mater. Sci. Ed. 34(1), 30–34 (2019)

L. Wu, J.L. Zhang, C.L. Wang, J.C. Li, J. Appl. Phys. 103(8), 084116 (2008)

H. Li, Y. Hao, Z. Lin, X. He, J. Cai, X. Gong, Y. Gu, R. Zhang, H. Cheng, B. Zhang, Solid State Commun. 353, 114871 (2022)

Y. Zhang, H. Li, M. Li, X. Xu, Ferroelectrics 570(1), 31–36 (2021)

X. Gao, Z. Cheng, Z. Chen, Y. Liu, X. Meng, X. Zhang, J. Wang, Q. Guo, B. Li, H. Sun, Q. Gu, H. Hao, Q. Shen, J. Wu, X. Liao, S.P. Ringer, H. Liu, L. Zhang, W. Chen, F. Li, S. Zhang, Nat. Commun. 12(1), 881 (2021)

Y. Qin, P. Yan, F. Han, Y. Zhang, Z. Lv, C. Zhou, J. Alloys Compd. 891, 161959 (2022)

X. Lv, N. Zhang, Y. Ma, X. Zhang, J. Wu, J. Mater. Sci. Technol. 130, 198–207 (2022)

J. Yin, J. Wu, H. Wang, J. Mater. Sci.: Mater. Electron. 28(6), 4828–4838 (2017)

L.-Q. Cheng, M. Feng, Y. Sun, Z. Zhou, Z. Xu, J. Adv. Ceram. 9(1), 27–34 (2020)

J. Li, J. Wang, F. Wu, H. Ma, T. Ma, Y. Tian, D. Liu, B. Yang, Coatings 12(4), 526 (2022)

K. Kirana, V. Gangadhar, G. Prasad, Mater. Today 11, 971–979 (2019)

H.-C. Cho, D.-Y. Lim, J.-H. Song, Crystals 12(6), 827 (2022)

J.B. Lim, Y.-H. Jeong, M.-H. Kim, D. Suvorov, J.-H. Jeon, Ceram. Int. 38(3), 2605–2608 (2012)

X. Shang, J. Guo, W. Xiao, Y. Lu, G. Chang, T. Zhou, Y. He, J. Electron. Mater. 43(5), 1424–1431 (2014)

L.D. Vuong, D.A. Quang, P. Van Quan, N. Truong-Tho, J. Electron. Mater. 49(11), 6465–6473 (2020)

B. Zhang, J. Wu, X. Wang, X. Cheng, J. Zhu, D. Xiao, Curr. Appl. Phys. 13(8), 1647–1650 (2013)

T. Wang, Y. Liao, D. Wang, Q. Zheng, J. Liao, F. Xie, W. Jie, D. Lin, J. Am. Ceram. Soc. 102(1), 351–361 (2019)

N. Truong-Tho, L.D. Vuong, J. Adv. Dielectr. 10(04), 2050011 (2020)

L.D. Vuong, P.D. Gio, J. Alloys Compd. 817, 152790 (2020)

H. Sun, J. Liu, X. Wang, Q. Zhang, X. Hao, S. An, J. Mater. Chem. C 5(35), 9080–9087 (2017)

N. Truong-Tho, D. Le Vuong, J. Mater. Sci.: Mater. Electron. 32(12), 16601–16611 (2021)

L. Egerton, D.M. Dillon, J. Am. Ceram. Soc. 42(9), 438–442 (1959)

Y. Zhao, Z. Xu, R. Chu, J. Hao, J. Du, G. Li, J. Mater. Sci.: Mater. Electron. 28(2), 1211–1216 (2017)

Y. Zhai, Y. Feng, J. Du, J. Xue, J. Shen, Y. Lu, T. Lu, P. Fu, W. Li, J. Hao, J. Mater. Sci.: Mater. Electron. 30(5), 4352–4358 (2019)

C. Shi, J. Ma, J. Wu, K. Chen, B. Wu, J. Mater. Sci.: Mater. Electron. 31(4), 2809–2816 (2020)

Acknowledgements

This research was funded by Ministry of Education and Training under Grant Number B2022-ĐHH-06.

Funding

This research was funded by Ministry of Education and Training under Grant Number B2022-ĐHH-06.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study concept and design including doing experiments as well as discussing writing the manuscript. The manuscript was read and approved by all authors.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Tu, L.T.U., Gio, P.D. Systematic study of the influence of the K/Na ratio on the structure, microstructure, and electrical properties of (KxNa1−x)NbO3 lead-free ceramics. J Mater Sci: Mater Electron 34, 217 (2023). https://doi.org/10.1007/s10854-022-09475-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10854-022-09475-0