Abstract

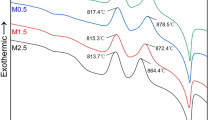

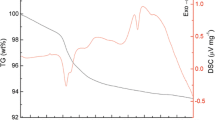

BaO–Al2O3–SiO2–B2O3 (BASB) glass-ceramic designed to replace the glass additive in traditional glass + ceramic composite system as LTCC material has been investigated. The influence of additive amount of glass former B2O3, network modifier BaO and network intermediate Al2O3 on the thermodynamic properties of BASB glass-ceramics is studied. The results show that the increase of both B2O3 and BaO can lower the softening and crystallization temperatures of the glass-ceramic. At the same time, the increase of BaO content leads to the reduction in sintering shrinkage rate. The addition of Al2O3 can decrease the crystallization temperature, but the softening temperature will exhibit a complicated variation of decreasing at first and then rising. Based on the aforementioned results, an optimum BASB glass-ceramic consisting of 13 mol% B2O3, 24 mol% BaO, 12 mol% Al2O3, 50 mol% SiO2, 1 mol% ZrO2 and 1 mol% Li2O is produced, with the softening temperature of 650 °C, main crystalline phase of BaAl2Si2O8 after being sintered at 850 °C and the crystallization activation energy of 292.25 kJ/mol. The received glass-ceramic is then employed as sintering aid to fabricate low-temperature-sintered BASB glass-ceramic + Al2O3 ceramic composite. The 55 wt.% BASB + 45 wt.% Al2O3 composite sintered at 850 °C shows attractive comprehensive properties with a density of 2.79 g/cm3, dielectric constant of 5.88@10 GHz and dielectric loss of 1.54 × 10–3@10 GHz, which makes it a good candidate for microwave LTCC substrate application.

Similar content being viewed by others

Data availability

The authors declare that all data generated during the study appear in the submitted article.

References

M.T. Sebastian, R. Ubic, H. Jantunen, Low-loss dielectric ceramic materials and their properties. Int. Mater. Rev. 60, 392–412 (2015)

H. Jantunen, T. Kangasvieri, J. Vähäkangas, S. Leppävuori, Design aspects of microwave components with LTCC technique. J. Eur. Ceram. Soc. 23, 2541–2548 (2003)

M.T. Sebastian, H. Jantunen, Low loss dielectric materials for LTCC applications: a review. Int. Mater. Rev. 53, 57–90 (2008)

Y. Imanaka, Multilayered Low Temperature Cofired Ceramics (LTCC) Technology (Springer, New York, 2005)

S.F. Wang, B.C. Lai, Y.F. Hsu, C.A. Lu, Physical and structural characteristics of sol–gel derived CaO–B2O3–SiO2 glass-ceramics and their dielectric properties in the 5G millimeter-wave bands. Ceram. Int. 48, 9030–9037 (2022)

X. Zhao, C. Gao, B. Li, Effect of CeO2 on sintering behavior, crystallization, and properties of CaO–Al2O3–SiO2 glass-ceramics for packages. J. Mater. Sci. Mater. Electron. 31, 17718–17725 (2020)

B.B. Lu, J. Huang, D.H. Jiang, J.J. Chen, J. Xu, J. Xi, G.H. Chen, F. Shang, J.W. Xu, C.L. Yuan, C.R. Zhou, Microwave dielectric properties of BaO–ZnO–B2O3–P2O5 glass-ceramic for LTCC application. J. Mater. Sci. Mater. Electron. 30, 18599–18605 (2019)

Z.W. Zhou, Y.X. Lin, J.F. Guo, X.S. Jiang, H.L. Sun, S. Chen, Influence of R2+ (R = Mg, Ca, Sr) partial substitution for Ba2+ on structures and the thermal properties of BaO–Al2O3–SiO2–B2O3 LTCC materials. J. Mater. Sci. Mater. Electron. 33, 3198–3207 (2022)

F. Liu, X.P. Huang, J.J. Qua, C.L. Yuan, G.H. Chen, R.F. Ma, Crystallization behavior, densification and microwave dielectric properties of MgO–Al2O3–SiO2–TiO2 system glass-ceramics containing V2O5. J Non-Cryst. Solids 481, 329–334 (2018)

C. Venkateswaran, H. Sreemoolanadhan, R. Vaish, Lithium aluminosilicate (LAS) glass-ceramics: a review of recent progress. Int. Mater. Rev. 67, 620–657 (2022)

P. Wu, H.Y. Yang, H.C. Yang, L. Gui, Y.C. Wang, Q. Liu, E.Z. Li, Synthesis of a low-firing BaSi2O5 microwave dielectric ceramics with low dielectric constant. Ceram. Int. 48, 17289–17297 (2022)

L. Gui, H.C. Yang, Q. Zhao, E.Z. Li, Synthesis of low temperature firing Scheelite-type BaWO4 microwave dielectric ceramics with high performances. Ceram. Int. 48, 1360–1365 (2022)

L. Zhang, S.Q. Yang, M.H. Xiao, L. Chen, J. Sun, J.J. Ding, X.X. Li, Y. Gong, K. Zheng, X. Zhang, X.Y. Tian, Influence of silicon carbide nanowires on the properties of Bi–B–Si–Zn–Al glass based low temperature co-fired ceramics. Ceram. Int. 48, 25382–25389 (2022)

Z.F. Liu, W.X. Liang, W.J. Zhang, F.L. Wang, Y. Xun, T.T. Chen, W. Li, X.Y. Chen, H.J. Mao, Effects of Pb–B–Si–O glass on the microstructures and electrical properties of silver electrode for LTCC application. J. Mater. Sci. Mater. Electron. 33, 17814–17827 (2022)

H.S. Ren, S.H. Jiang, M.Z. Dang, T.Y. Xie, H. Tang, H.Y. Peng, H.X. Lin, L. Luo, Investigating on sintering mechanism and adjustable dielectric properties of BLMT glass/Li2Zn3Ti4O12 composites for LTCC applications. J. Alloys Compd. 740, 1188–1196 (2018)

L.T. Xiang, C.W. Zhong, T.Y. Qin, M.X. Wang, D.S. Liu, B. Tang, S.R. Zhang, Densification, flexural strength and dielectric properties of CaO–MgO–ZnO–SiO2/Al2O3 glass ceramics for LTCC applications. Ceram. Int. 47, 28904–28912 (2021)

F.L. Wang, W.J. Zhang, X.Y. Chen, H.J. Mao, Z.F. Liu, S.X. Bai, Low temperature sintering and characterization of La2O3–B2O3–CaO glass-ceramic/LaBO3 composites for LTCC application. J. Eur. Ceram. Soc. 40, 2382–2389 (2020)

J.F. Guo, Y.X. Lin, Z.W. Zhou, L. Jin, S. Chen, Design and preparation of BaO–Al2O3–SiO2–B2O3/Quartz LTCC composites with tailored coefficient of thermal expansion. Ceram. Int. 48, 12065–12073 (2022)

M.K. Mahapatra, K. Lu, Glass-based seals for solid oxide fuel and electrolyzer cells—a review. Mater. Sci. Eng. R 67, 65–85 (2010)

B. Zhang, F. He, X.H. Cao, M.J. Wei, C.C. Zheng, J.L. Xie, The effect of TiO2 and B2O3 on sintering behavior and crystallization behavior of SrO–BaO–B2O3–SiO2 glass-ceramics. Ceram. Int. 48, 7013–7023 (2022)

A. Goel, D.U. Tulyaganov, V.V. Kharton, A.A. Yaremchenko, S. Eriksson, J.M.F. Ferreira, Optimization of La2O3-containing diopside based glass-ceramic sealants for fuel cell applications. J Power Sources 189, 1032–1043 (2009)

D.P. Mukherjee, S.K. Das, Effects of nano silica on synthesis and properties of glass ceramics in SiO2–Al2O3–CaO–CaF2 glass system: a comparison. J Non-Cryst. Solids 368, 98–104 (2013)

M.K. Zitani, M. Rezvani, R.A. Tabrizi, Crystallization, sinterability and microwave dielectric properties of CaO–SiO2–Na2O–MgO glass ceramics containing Fe2O3 and ZnO. Electron. Mater. Lett. 10, 131–137 (2014)

F. He, Q. Zhou, J. Xie, Q. Zhang, Characterization of low sintering temperature and high strength SiO2–B2O3–CaO vitrified bonds for diamond abrasive tools. Ceram. Int. 41, 3449–3455 (2015)

H. Scholze, A.C. Claus, Glass: nature, structure, and properties. Appl. Opt. 31, 31 (1992)

P. Zhang, Z. Chen, B. Li, Effect of BaO on crystallization, sintering, and properties of MgO–Al2O3–SiO2 glass-ceramics. J. Mater. Sci. Mater. Electron. 33, 2846–2854 (2022)

B.O. Mysen, D. Virgo, I. Kushiro, The structural role of aluminum in silicate melts—a Raman spectroscopic study at 1 atmosphere. Am. Miner. 66, 678–701 (1981)

Y.D. Chen, S.J. Liu, Y.Y. Zhou, P.K. Shang, Z.T. Shan, J. Zhang, Effect of Al2O3 content on amorphous phase-separation and self-limited crystallization of phosphosilcate glasses. J Non-Cryst. Solids 584, 121505 (2022)

H.J. Mao, X.Y. Chen, F.L. Wang, W.J. Zhang, Effects of alkaline earth oxides on the densification and microwave properties of low-temperature fired BaO–Al2O3–SiO2 glass-ceramic/Al2O3 composites. J Mater. Sci. 54, 12371–12380 (2019)

Z.X. Li, H.J. Mao, Y.W. Zhang, W.J. Zhang, Influences of glass content on the microstructure and properties of BaO–CaO–Al2O3–SiO2 glass/alumina composite for LTCC applications. IOP Conf. Ser. Mater. Sci. Eng. 292, 012082 (2018)

Acknowledgements

This work was supported by the Natural Science Foundation of Hunan Province of China (Grant No. 2018JJ3602).

Author information

Authors and Affiliations

Contributions

HM performed the experiments, data analysis and wrote the manuscript. FW and XZ contributed to the data analysis and manuscript preparation significantly. CX and WL helped to perform the data analysis with constructive discussions. WZ contributed to the conception of the study.

Corresponding author

Ethics declarations

Conflict of interest

The authors have no conflicts of interest to declare that are relevant to the content of this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Mao, H., Wang, F., Zhu, X. et al. Design of a BaO–Al2O3–SiO2–B2O3 glass-ceramic for microwave LTCC substrate material based on glass-ceramic + ceramic composite. J Mater Sci: Mater Electron 33, 24834–24844 (2022). https://doi.org/10.1007/s10854-022-09194-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-022-09194-6