Abstract

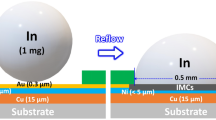

Indium has gained attention as a thermal interface material (TIM), in high-power electronics, due to its high thermal conductivity and mechanical compliance. However, there is minimal understanding of the indium microstructure as it is challenging to analyze due to its softness. Samples with indium are difficult to cross-section; conventional mechanical polishing is considered impractical. Instead, slow and expensive focused ion beam techniques have been required. In this study, a cross-section procedure for components with indium was developed based on mechanical polishing, ultrasonic cleaning, etching, and ion milling. With this technique, indium cross-sections that showed microstructural details could be made and studied for changes across different bond metallizations and thermal histories. Electronic packages with indium TIM bonded to Au or Ag metalized Si chips and Ni-coated Cu lids were examined. Intermetallic compounds between In–Au, In–Ag, and In–Ni were investigated with scanning electron microscopy and energy-dispersive X-ray spectroscopy. The effects of bond metallization, doping, and solder reflow cycles (thermal history) on the indium microstructures were examined.

Similar content being viewed by others

Data availability

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

X. Luo, Y. Zhang, C. Zandén, M. Murugesan, Y. Cao, L. Ye, J. Liu, J. Mater. Sci. 25, 2333–2338 (2014)

J. Hansson, C. Zandén, L. Ye, J. Liu, IEEE-NANO 371–374 (2016)

C. Deppisch, T. Fitzgerald, A. Raman, F. Hua, C. Zhang, P. Liu, M. Miller, JOM 58(6), 67–74 (2006)

W.J. Plumbridge, J. Mater. Sci. 31, 2501–2514 (1996)

T. Fałat, P. Matkowski, B. Płatek, C. Zandén, J. Felba, L.-L. Ye, J. Liu, EMPC (2013)

B. Carlberg, L. Ye, J. Liu, Mater. Lett. 75, 229–232 (2012)

M. Raza, A. Westwood, A.P. Brown, C. Stirling, J. Mater. Sci. 23, 1855–1863 (2012)

B. Carlberg, T. Wang, J. Liu, D. Shangguan, Microelectron. Int. 26, 28–36 (2009)

R. Prasher, Proc. IEEE 94, 1571–1586 (2006)

T. Jensen, R. Lasky, Pan Pacific, 1–9 (2020)

M. Plötner, B. Donat, A. Benke, Cryogenics 31, 159–162 (1991)

F. George, V. Voort, Metallography principles and practice (ASM International, Almere, 1984), pp.136–138

Y.F. Lin, H. Hung, H.Y. Yu, C. Kao, Y. Wang, J. Mater. Sci. 31, 10161–10169 (2020)

Y. Tian, C. Liu, D. Hutt, B. Stevens, J. Electron. Mater. 43, 594–603 (2014)

C. Dasarathy, Pract. Metallogr. 7, 44–46 (1970)

C. Dasarathy, Metall. Mater. Trans. B 1, 1784–1786 (1970)

L.D.D. Morais, S. Chevalliez, S. Mouleres, Microelectron. Reliab. 54(9–10), 1802–1805 (2014)

J.R. Michael, D. Perry, D.P. Cummings, J. Walraven, M. Jordan, Micros. Microanal. (2022). https://doi.org/10.1017/S1431927622000496

T. Dang, D. Shima, G. Balakrishnan, A. Chen, R. Bedford, J. Vac. Sci. Technol. B 30(6), 060602 (2012)

L.D.D. Morais, S. Chevalliez, S. Mouleres, Microelectron. Reliab. 54, 1802–1805 (2014)

L.-C. Huang, Y.-P. Zhang, C.-M. Chen, L.-Y. Hung, Y.-P. Wang, Mater. Charact. 184, 111673 (2022)

F. Shieu, C.-C. Chen, J.G. Sheen, Z. Chang, Thin Solid Films 346, 125–129 (1999)

Y.M. Liu, T. Chuang, J. Electron. Mater. 29, 405–410 (2000)

K. YunAh, B. JoHyun, J. HyunHye, C. MiKyoung, K. YoungDo, R. DongSu, P. DongJoo, K. JinYong, ECTC (2021)

Y.-Y. Wu, W. P. Lin, C. C. Lee, IEEE Int. Symp. Adv. Packag. Mater. (2013)

S. Hassam, J. Rogez, Z. Bahari, J. Chem. Thermodyn. 70, 168–175 (2014)

Acknowledgements

The authors would like to acknowledge Indium Corporation® for providing the BGA samples and the financial support of this study by Universal Instruments’ AREA Consortium.

Funding

This work was supported by Universal Instruments’ AREA Consortium.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conceptions and design. Sample preparation was done by YW. All authors contributed to the analysis and writing the manuscript. All authors have read and approved the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors have no relevant financial or non-financial interests to disclose.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

McClure, P., Wang, Y. Indium thermal interface material microstructure as a function of thermal history and bonding metallization. J Mater Sci: Mater Electron 33, 22810–22820 (2022). https://doi.org/10.1007/s10854-022-09048-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-022-09048-1