Abstract

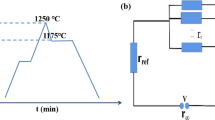

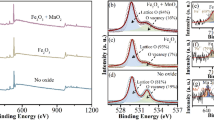

In this study, the alkali metal (Li/Na/K) doping has been achieved by using the sol–gel method, and the thermally sensitive ceramic Mn1.2Ni0.3Co1.5−x (Li/Na/K)xO4 has been subsequently obtained by the traditional solid-phase sintering and two-step sintering methods. XRD results revealed that the doping of Li/Na/K did not introduce any impurity phases other than the cubic spinel phase of MnCo2O4. The SEM analysis demonstrated that the doping of Li enhanced the grain size, whereas the Na and K doping decreased the grain size from 3.98 μm and 3.23 μm to 3.58 μm and 2.71 μm. In addition, the grain size of the ceramic samples sintered in the second step was noted to be relatively uniform. For the Li-doped samples, the resistivity of the traditional and two-step sintered thermal ceramic samples exhibited an increasing trend from 6.17 μm and 6.5 μm to 12.72 μm and 7.88 μm. The alkali metal (Li/Na/K) doping reduced the resistivity of the Mn1.2Ni0.3Co1.5−xAXO4 (A = Li, Na, K) thermal ceramics. The findings reported in this study confirm that the Mn1.2Ni0.3Co1.5−x (Li/Na/K)xO4 family exhibits a high potential of as the low-temperature NTC heat-sensitive materials. The alkali-metal-doped manganese-based ceramics are traditionally thermally sensitive materials with high resistance and high B, while low B high-resistance materials have rarely been reported.

Similar content being viewed by others

References

T. Zhu, Z.Y. Ang, G.W. Ho, R.S.C. Adv, Self-assembly formation of NiCo2O4 superstructures with porous architectures for electrochemical capacitors. RSC Adv. 5(66), 53259–53266 (2015)

U.K. Sinha, B. Dasand, P. Padhan, Interfacial reconstruction in the La0.7Sr0.3MnO3 thin films: giant low-field magnetoresistance. Nanoscale Adv. (2020). https://doi.org/10.1039/d0na00287a

A. Feteira, Negative temperature coefficient resistance (NTCR) ceramic thermistors: an industrial perspective. J. Am. Ceram. Soc. 92(5), 967–983 (2009)

L.L. Hench, J. West, The sol-gel process. Chem. Rev. 90, 33–72 (1990)

H.M. Zhang, A.M. Chang, G. Fang, L.J. Zhao, Q. Zhao, J.C. Yao, X. Huang, The optimal synthesis condition by sol–gel method and electrical properties of Mn1.5−xCo1.5NixO4 ceramics. Ceram. Int. 40(6), 7865–7872 (2014)

H.B. Li, T.I.P. Ley, X.H. Ma, X. Sang, H.M. Zhang, A.M. Chang, Electrical properties and aging behavior of Na-doped Mn1.95Co0.21Ni0.84O4 NTC ceramics. Ceram. Int. (2020). https://doi.org/10.1016/j.ceramint.2020.06.218

S. Liang, D.D. Zhao, M.M. Cui, H.B. Li, X. Zhang, Two-step sintering of submicro-grain Ni0.54Mn1.26Fe1.2O4 NTC ceramics with an excellent electrical performance. J. Mater. Sci.: Mater. Electron. 30, 20144–20153 (2019)

Y.F. Zhao, Y.X. Xie, F. Zhang, Liquid phase sintering and properties of Mn0.6Ni0.9Co1.5-xLixO4-LiF thermosensitive ceramics. J. Mater. Sci.: Mater. Electron. (2020). https://doi.org/10.1007/s10854-020-04536-8

Y.F. Zhao, Y.X. Xie, NTC thermo-sensitive ceramics with low B value and high resistance at low temperature in Li-doped Mn0.6Ni0.9Co1.5O4 system. J. Mater. Sci.: Mater. Electron. 31(2), 1403–1410 (2020)

B. Wang, J.H. Wang, A.M. Chang, J.C. Yao, Bismuth trioxide-tailored sintering temperature, microstructure and NTCR characteristics of Mn1.1Co1.5Fe0.4O4 ceramics. RSC Adv. 9, 25488 (2019)

J.J. Zhang, Y. Zheng, J.X. Chen, W. Zhou, Y.J. Zhao, P. Feng, Microstructures and mechanical properties of Mo2FeB2-based cermets prepared by two-step sintering technique. Int. J. Refract. Metal. Hard Mater. 72, 56–62 (2018)

J.D. Bolton, A.J. Gant, Microstructural development and sintering kinetics in ceramic reinforced high speed steel metal matrix composites. Powder Metall. 40(2), 143–151 (1997)

X. Huang, T.P. Xiu, M.E. Badding, Z.Y. Wen, Two-step sintering strategy to prepare dense Li-garnet electrolyte ceramics with high Li+ conductivity. Ceram. Int. 44, 5660–5667 (2018)

R. Takano, K. Tadanaga, A. Hayashi, M. Tatsumisago, Low temperature synthesis of Al-doped Li7La3Zr2O12 solid electrolyte by a sol-gel process. Solid State Ion. 255, 104–107 (2014)

X.M. Pang, J.H. Qiu, K.J. Zhu, J.Z. Du, (K, Na)NbO3-based lead-free piezoelectric ceramics manufactured by two-step sintering. Ceram. Int. 38, 2521–2527 (2012)

J.H. Ji, J. Kim, J.H. Koh, Improved dielectric and piezoelectric properties of K/Na excessed (Na, K)NbO3 lead-free ceramics by the two step sintering process. J. Alloys Compd. 698, 938–943 (2017)

J.L. Zhang, Y.L. Qin, Y. Gao, W.Z. Yao, M. Zhao, Improvement of physical properties for KNN-based ceramics by modified two-step sintering. J. Am. Ceram. Soc. 97(3), 759–764 (2014)

D. Fan, L.-Q. Chen, S.-P.P. Chen, Numerical simulation of zener pinning with growing second-phase particles. J. Am. Ceram. Soc. 81, 526–532 (1998)

A. Hjm, A. Wkj, B. Smy, Microstructural freezing of highly NIR transparent Y2O3-MgO nanocomposite via pressure-assisted two-step sintering. J. Eur. Ceram. Soc. 39(15), 4957–4964 (2019)

C.J. Ma, H. Gao, TEM and electrical properties characterizations of Co0.98Mn2.02O4 NTC ceramic. J. Alloys Compd. 749, 853–858 (2018)

X. Sun, S.L. Leng, H. Zhang, Z.L. He, Z.C. Li, Electrical properties and temperature sensitivity of Li/Mg modified Ni0.7Zn0.3O based ceramics. J. Alloys Compd. 763, 975–982 (2018)

X. Sun, Z.C. Li, W.Y. Fu, S.Y. Chen, H. Zhang, Li/Fe modified Zn0.3Ni0.7O NTC thermistors with adjustable resistivities and temperature sensitivity. J. Mater. Sci.: Mater. Electron. 29, 343–350 (2018)

A.N. Kamlo, J. Bernard, C. Lelievre, D. Houivet, Synthesis and NTC properties of YCr1−xMnxO3 ceramics sintered under nitrogen atmosphere. J. Eur. Ceram. Soc. 31, 1457–1463 (2011)

W.G. Wang, X.P. Wang, Y.X. Gao, G.L. Hao, W.Q. Ma, Q.F. Fang, Internal friction study on the lithium ion diffusion of Li5La3M2O12 (M = Ta, Nb) ionic conductors. Solid State Sci. 13, 1760–1764 (2011)

X.P. Wang, Q.F. Fang, Mechanical and dielectric relaxation studies on the mechanism of oxygen ion diffusion in La2Mo2O9. Phys. Rev. B 65(6), 064304 (2002)

Acknowledgements

The authors acknowledge the financial support of the key R & D project of China Xinjiang Uygur Autonomous Region (Grant No. 2021B01001-4).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors have not disclosed any competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhao, Y., Deng, W., Chen, X. et al. Effect of A (A = Li, Na, K) doping on structure and electrical properties of Mn1.2Ni0.3Co1.5O4 polycrystalline ceramics. J Mater Sci: Mater Electron 33, 22448–22455 (2022). https://doi.org/10.1007/s10854-022-09021-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-022-09021-y