Abstract

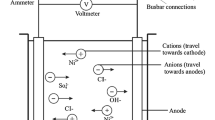

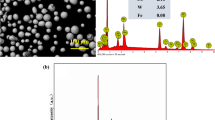

Ceramic coatings were fabricated on titanium substrate by the micro-arc oxidation (MAO) treatment in compound electrolyte with different Ce(NO3)3 contents (0, 1, 2, 3, and 4 g/L). To analyze the microstructure, phase structure, and elemental composition of the MAO coatings, scanning electron microscopy (SEM), X-ray diffraction (XRD), and energy-dispersive spectroscopy (EDS) were employed. The results displayed that the porous coatings were mainly composed of TiO2 and CeO2 from Ce(NO3)3 in the electrolyte. As the concentration of Ce(NO3)3 increased, the average thickness and density of the ceramic coatings increased obviously. The adhesion of the MAO coatings to the substrate increased firstly and then decreased. The electrochemical tests and cavitation experiments were applied to evaluate the corrosion resistance of the samples before and after MAO treatment. The optimal corrosion resistance was obtained when the concentration of Ce(NO3)3 was 2 g/L in polarization cure and cavitation erosion tests. These results indicated that the MAO coatings with different Ce(NO3)3 concentrations provide preferable protection for titanium substrate. Finally, the formation mechanism of the CeO2–TiO2 composite MAO coatings was proposed.

Similar content being viewed by others

Data availability

The data that support the findings of this study are available from the corresponding author upon reasonable request.

Code availability

Not applicable.

References

L.Y. Han, X. Li, F. Xue, C.L. Chu, J. Bai, Biocorrosion behavior of micro-arc-oxidized AZ31 magnesium alloy in different simulated dynamic physiological environments. Surf. Coat. Technol. 361, 240–248 (2019)

D.R. Lopes, C.L.P. Silva, R.B. Soares, P.H.R. Pereira, A.C. Oliveira, R.B. Figueiredo, T.G. Langdon, V.F.C. Lins, Cytotoxicity and corrosion behavior of magnesium and magnesium alloys in hank’s solution after processing by high-pressure torsion. Adv. Eng. Mater. 21(8), 1900391 (2019)

M. Shokouhfar, S.R. Allahkaram, Formation mechanism and surface characterization of ceramic composite coatings on pure titanium prepared by micro-arc oxidation in electrolytes containing nanoparticles. Surf. Coat. Technol. 291, 396–405 (2016)

M. Shokouhfar, S.R. Allahkaram, Effect of incorporation of nanoparticles with different composition on wear and corrosion behavior of ceramic coatings developed on pure titanium by micro arc oxidation. Surf. Coat. Technol. 309, 767–778 (2017)

U. Diebold, The surface science of titanium dioxide. Surf. Sci. Rep. 48, 53–229 (2003)

K. Sakata, K. Tagomori, N. Sugiyama, M. Takenouchi, Y. Shinya, K. Morimoto, Y. Suzuki, Development of nanoporous alumina catalyst support by anodic oxidation of thermally and kinetically sprayed aluminum coatings. J. Therm. Spray. Technol. 22, 138–144 (2013)

R.T.R. McGrann, D.J. Greving, J.R. Shadley, E.F. Rybicki, T.L. Kruecke, B.E. Bodger, The effect of coating residual stress on the fatigue life of thermal spray-coated steel and aluminum. Surf. Coat. Technol. 108–109, 59–64 (1998)

P. Xiong, J. Yan, P. Wang, Z. Jia, W. Zhou, W. Yuan, Y. Li, Y. Liu, Y. Cheng, D. Chen, Y. Zheng, A pH-sensitive self-healing coating for biodegradable magnesium implants. Acta Biomater. 98(15), 160–173 (2019)

J. Senf, E. Broszeit, Maximizing the benefit of aluminizing to AZ31 alloy by surface nanocrystallization for elevated resistance to wear and corrosive wear. Adv. Eng. Mater. 1, 133–137 (1999)

S. Sanjay, K. Baskar, Controlled growth of gallium nitride nanowires on silicon and their utility in high performance Ultraviolet–A photodetectors. Appl. Surf. Sci. 456, 526–531 (2018)

N.A. Costa, D.R.N. Correa, P.N. Lisboa-Filho, T.S.P. Sousa, C.R. Grandini, L.A. Rocha, Influence of the molybdenum on characteristics of oxide films produced by micro-arc oxidation on Ti-15Zr-based alloys. Surf. Coat. Technol. 408, 126856 (2021)

K. Aramaki, A self-healing protective film prepared on zinc by treatment in a Ce(NO3)3 solution and modification with Ce(NO3)3. Corros. Sci. 47, 1285–1298 (2005)

Z.Y. Li, Z.B. Cai, Y. Cui, Effect of oxidation time on the impact wear of micro-arc oxidation coating on aluminum alloy. Wear. 426–427, 285–295 (2019)

M. Laleh, F.A. Kargar, S. Rouhaghdam, Investigation of rare earth sealing of porous micro-arc oxidation coating formed on AZ91D magnesium alloy. J. Rare Earths 30(11), 1293–1297 (2012)

M. Atapour, C. Blawert, M.L. Zheludkevich, The wear characteristics of CeO2 containing nanocomposite coating made by aluminate-based PEO on AM 50 magnesium alloy. Surf. Coat. Technol. 357, 626–637 (2019)

Z.G. Zheng, M.C. Zhao, L.L. Tan, Y.C. Zhao, B. Xie, D.F. Yin, K. Yang, A. Atrens, Corrosion behavior of a self-sealing coating containing CeO2 particles on pure Mg produced by micro-arc oxidation. Surf. Coat. Technol. 386, 125456 (2020)

J.Z. Li, Y.W. Tian, Z.X. Cui, Z.Q. Huang, Effects of rare earths on the micro arc oxidation of an Mg alloy. Rare Met. 27(1), 50 (2008)

Y. Gong, J.W. Geng, J. Huang, Z. Chen, M.L. Wang, D. Chen, H.W. Wang, Self-healing performance and corrosion resistance of novel CeO2-sealed MAO film on aluminum alloy. Surf. Coat. Technol. 417, 127208 (2021)

D.J. Shen, H.J. Ma, C.H. Guo, J.R. Cai, G.L. Li, D.L. He, Q.X. Yang, Effect of cerium and lanthanum additives on plasma electrolytic oxidation of AZ31 magnesium alloy. J. Rare Earths 12, 1208 (2013)

S.W. Guan, M. Qi, Y.D. Li, W.Q. Wang, Morphology evolution of the porous coatings on Ti–xAl alloys by Al adding into Ti during micro-arc oxidation in Na2B4O7 electrolyte. Surf. Coat. Technol. 395, 125948 (2020)

T. Cheng, Y. Chen, X. Nie, Surface morphology manipulation and wear property of bioceramic oxide coatings on titanium alloy. Surf. Coat. Technol. 215, 253–259 (2013)

S.N. Sun, G. Ye, Z. Lu, Y. Weng, G.F. Ma, J. Liu, Surface treatment of Zn-Mn-Mg alloys by micro-arc oxidation in silicate-based solutions with different NaF concentrations. Materials. 14, 4289 (2021)

T.S. Hu, Z.J. Shi, W. Shao, X.L. Xing, Y.F. Zhou, Q.X. Yang, Effect of CeO2 on density and wear resistance of Ni-Cr-WC coatings by theoretical calculation and experimental investigation. Surf. Coat. Technol. 377, 124850 (2019)

A. Gilbert, A.G.W. Cameron, A composite nuclear-level density formula with shell corrections. Can. j. phys. 43(8), 1446 (1965)

Q. Chen, Study on the composition structure and performance of ZrO2-Y2O3 multi-phase ceramics (2018)

J.F. Wang, Preparation and performance of anti-wear oxide film by micro-arc oxidation on 6061 aluminum alloy (2018)

W.L. Lv, Control principle of fabrication and characterization for micro-structure and properties of microarc oxidation coatings on AZ91D magnesium alloys (2010)

L. Zhao, The study on the performance of hydroxyapatite film prepared on the TC4 titanium alloy by micro arc oxidation (2013)

S.C. Di, Y.P. Guo, H.W. Lv, J. Yu, Z.W. Li, Microstructure andpropertiesofrareearthCeO2-doped TiO2 nanostructured composite coatings through micro-arc oxidation. Ceram. Int. 41, 6178–6186 (2015)

P. Du, S.F. Yan, W.D. Chen, S.J. Li, W. Ma, Graphene concentration on micro-arc oxidation ceramic layer of ZrH1.8 surface. J. INORG. MATER. 34(11), 1175–1180 (2019)

S.J. Li, S.F. Yan, X.K. Zhong, W.D. Chen, P. DU, S.H. Yang, W. Ma, Effect of cerium oxide on ZrH1.8 surface micro-arc oxidation composite ceramic layer. Surf. Technol. 48(4), 279–284 (2019)

I.M. Low, D. Lawrence, R.I. Smith, Factors controlling the thermal stability of aluminum titanate ceramics in vacuum. J. Am. Ceram. Soc. 88, 2957–2961 (2005)

N. Qiu, Experimental research on cavitation erosion of impeller materials (2016)

Z. Yang, J.M. Tian, Cavitation erosion of structural ceramics. J. Funct. 34(2), 200–202 (2003)

F.B. Liu, J.D. Wang, D.R. Chen, M. Zhao, The cavitation erosion of the mild carbon steels implanted with titanium and nitrogen. Adv. Tribol. 1, 780–781 (2009)

F. Cheng, S.Y. Jiang, J. Liang, Cavitation erosion resistance of microarc oxidation coating on aluminum alloy. Appl. Surf. Sci. 280, 287–296 (2013)

J.A. Dean, Lange’s Handbook of Chemistry, 14th edition (McGraw–Hill, New York, 1992)

O. Khaseleve, D. Weiss, J. Yahalom, Structure and composition of anodic films formed on binary Mg-Al alloys in KOH-aluminate solutions under continuous sparking. Corros. Sci. 43, 1295–1307 (2001)

T.S. Lim, H.S. Ryu, S.H. Hong, Electrochemical corrosion properties of CeO2-containing coatings on AZ31 magnesium alloys prepared by plasma electrolytic oxidation. Corros. Sci. 62, 104–111 (2012)

H. Duan, C. Yan, F. Wang, Growth process of plasma electrolytic oxidation films formed on magnesium alloy AZ91D in silicate solution. Electrochim. Acta 52(15), 5002–5009 (2007)

R.O. Hussein, X. Nie, D.O. Northwood, An investigation of ceramic coating growth mechanisms in plasma electrolytic oxidation (PEO) processing. Electrochim. Acta 112, 111–119 (2013)

A.L. Yerokhin, X. Nie, A. Leyland, A. Matthews, Characterisation of oxide films produced by plasma electrolytic oxidation of a Ti–6Al–4V alloy. Surf. Coat. Technol. 130, 195–206 (2000)

X. Wang, B. Li, L. Zhou, J. Ma, X. Zhang, H. Li, C. Liang, S. Liu, H. Wang, Influence of surface structures on biocompatibility of TiO2/HA coatings prepared by MAO. Mater. Chem. Phys. 215, 339–345 (2018)

R.O. Hussein, X. Nie, D.O. Northwood, A spectroscopic and microstructural study of oxide coatings produced on a Ti–6Al–4V alloy by plasma electrolytic oxidation. Mater. Chem. Phys. 134, 484–492 (2012)

X.Q. Cao, J. Zhou, H.N. Wang, S. Li, W.G. Wang, W. Qin, Abnormal thermal stability of sub-10 nm Au nanoparticles and their high catalytic activity. J. Mater. Chem. A, 7, 10980–10987 (2019)

S.G. Lim, H.C. Choe, Bioactive apatite formation on PEO-treated Ti-6Al-4V alloy after 3rd anodic titanium oxidation. Appl. Surf. Sci. 477, 50–59 (2019)

M. Kaseema, H.C. Choe, The effect of in-situ reactive incorporation of MoOx on the corrosion behavior of Ti-6Al-4 V alloy coated via micro-arc oxidation coating. Corros. Sci. 192, 109764 (2021)

Acknowledgements

This work was supported by Shenyang Science and Technology Plan Project (Grant No. 20-202-1-12) and Central Funding Project for Local Science and Technology Development (Grant No. 2022JH6/100100048).

Funding

This work was supported by Shenyang Science and Technology Plan Project (Grant No. 20-202-1-12) and Central Funding Project for Local Science and Technology Development (Grant No. 2022JH6/100100048).

Author information

Authors and Affiliations

Contributions

HL: Literature research, Formal analysis, Investigation, Writing—original draft, and Data curation. GM: Resources and Funding acquisition. SS: Methodology and Conceptualization. ZW: Methodology and Proofreading. DS: Calculation and Software.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Li, H., Ma, G., Sun, S. et al. In-situ synthesis and characterization of CeO2–TiO2 composite coatings on titanium substrate by micro-arc oxidation. J Mater Sci: Mater Electron 33, 22332–22345 (2022). https://doi.org/10.1007/s10854-022-09012-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-022-09012-z