Abstract

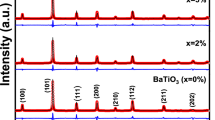

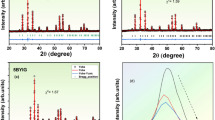

(Zr0.8Sn0.2)TiO4 (ZST) ceramics were prepared by solid-phase method. The effects of MgO/La2O3/Nb2O5 doped on the phase composition, microstructure, sintering behavior, and microwave dielectric properties of ZST ceramics were investigated. XRD analysis showed that the major crystalline phase was ZST. Very small amounts of phases, Nb2O5 and Mg(Ti2O5), were observed when dopants were added, and Nb2O5 inhibited the formation of Mg(Ti2O5). The results showed that upon adding 7 wt% Nb2O5 and small amounts of MgO and La2O3 to the ceramics, the permittivity of the ceramics was greatly reduced compared to that of other oxide-doped (Zr, Sn)TiO4 ceramic materials, and the Q × f value was also increased. The coefficients of thermal expansion of ZST ceramics in this study were within the range reported in the literature. Optimal dielectric properties, εr = 34.78, Q × f = 55,190 GHz (f = 5.8 GHz), τf = − 13.86 ppm/°C, and CTE = 7.0 ppm/°C, were achieved for the sample with 7 wt% Nb2O5 sintered at 1330 °C for 2 h.

Similar content being viewed by others

Data availability

All data generated or analyzed during this study are included in this published article.

Code availability

Not applicable.

References

J.R. Sanchez, C. Bachiller, M. Julia, V. Nova, H. Esteban, V.E. Boria, IEEE Microw Wirel. Compon. Lett. 28, 990 (2018). https://doi.org/10.1109/lmwc.2018.2871644

R. Muhammad, Y. Iqbal, J. Mater. Sci. Mater. Electron. 26, 9092 (2015). https://doi.org/10.1007/s10854-015-3596-9

R. Muhammad, Y. Iqbal, Mater. Lett. 153, 121 (2015). https://doi.org/10.1016/j.matlet.2015.04.021

C.L. Huang, C.S. Hsu, R.J. Lin, Mater. Res. Bull. 36, 1985 (2001). https://doi.org/10.1016/s0025-5408(01)00677-8

C.L. Huang, M.H. Weng, H.L. Chen, Mater. Chem. Phys. 71, 17 (2001). https://doi.org/10.1016/s0254-0584(00)00528-9

M. Saleem, Y. Iqbal, S. Qin, X. Wu, R. Muhammad, F. Zhu, J. Mater. Sci. Mater. Electron. 26, 1507 (2014). https://doi.org/10.1007/s10854-014-2568-9

R. Muhammad, Y. Iqbal, J. Mater. Sci. Mater. Electron. 26, 4870 (2015). https://doi.org/10.1007/s10854-015-2995-2

A. Tumuluri, R.M.S. Raju, K.C.J. Raju, V. Seshubai, T. Rajasekharan, Mater. Lett. 154, 128 (2015). https://doi.org/10.1016/j.matlet.2015.04.062

D. Pamu, G.L.N. Rao, K.C.J. Raju, J. Alloy. Compd. 509, 9289 (2011). https://doi.org/10.1016/j.jallcom.2011.06.033

Y.S. Ahn, K.H. Yoon, E.S. Kim, J. Eur. Ceram. Soc. 23, 2519 (2003). https://doi.org/10.1016/s0955-2219(03)00143-2

B. Chen, L. Han, B. Li, J. Mater. Sci. Mater. Electron. 30, 2847 (2018). https://doi.org/10.1007/s10854-018-0561-4

L. Qian, H. Zhou, Q. Jiang, L. Ren, W. Xie, X. Luo, Q. Sun, J. Mater. Sci. Mater. Electron. 27, 6183 (2016). https://doi.org/10.1007/s10854-016-4547-9

Y.U.E. Zhen-Xing, Z.H.U. Hai-Kui, W. Ya-Zhou, Q. Lei, Z. Hong-Qing, S.U.N. Qing-Lei, J Inorg Mater. 31, 812 (2016)

Q. Sun, H. Zhou, H. Zhu, H. Qi, L. Hu, Z. Yue, J. Mater. Sci. Mater. Electron. 27, 7750 (2016). https://doi.org/10.1007/s10854-016-4762-4

L. Zhang, Y. Chang, M. Xin, L. Ren, X. Luo, H. Zhou, J. Mater. Sci. Mater. Electron. 30, 491 (2018). https://doi.org/10.1007/s10854-018-0314-4

H. Zhu, Z. Cui, C. Shen, J. Mater. Sci. Mater. Electron. 27, 177 (2015). https://doi.org/10.1007/s10854-015-3734-4

L.Z. Wang, L.X. Wang, Z.F. Wang, B.Y. Huang, Q.T. Zhang, Z.X. Fu, J. Mater. Sci. Mater. Electron. 26, 9026 (2015). https://doi.org/10.1007/s10854-015-3586-y

Q. Sun, H. Zhou, X. Luo, L. Hu, L. Ren, Ceram. Int. 42, 12306 (2016). https://doi.org/10.1016/j.ceramint.2016.05.002

D. Pamu, G.L.N. Rao, K.C.J. Raju, Adv. Appl. Ceram. 106, 202 (2007). https://doi.org/10.1179/174367607x178157

A. Ioachim, M.G. Banciu, M.I. Toacsen, L. Nedelcu, D. Ghetu, H.V. Alexandru, C. Berbecaru, A. Dutu, G. Stoica, Appl. Surf. Sci. 253, 335 (2006). https://doi.org/10.1016/j.apsusc.2006.06.006

J.H. Jean, S.C. Lin, J. Am. Ceram. Soc. 83, 1417 (2000). https://doi.org/10.1111/j.1151-2916.2000.tb01404.x

Y.-J. Gu, Q.-F. Wang, Q. Li, J.-L. Huang, L.-H. Li, M. Chen, S. Gao, B.-H. Kim, J. European Ceram. Soc. 41, 7689 (2021). https://doi.org/10.1016/j.jeurceramsoc.2021.08.011

H.P. Hakki, P.D. Coleman, IEEE. Trans. Microw. Theory. Tech. 8, 402 (1960). https://doi.org/10.1109/TMTT.1960.1124749

W.E. Courtney, IEEE. Microw. Theory. Tech. 18, 476 (1970). https://doi.org/10.1109/TMTT.1970.1127271

W.C. Lee, J. Mater. Sci. 32, 6657 (1997). https://doi.org/10.1023/a:1018656521010

M.G. Brik, I.V. Kityk, J. Phys. Chem. Solids. 80, 119 (2015). https://doi.org/10.1016/j.jpcs.2015.02.002

K.H. Yoon, Y.S. Kim, E.S. Kim, J. Mater. Res. 10, 2085 (1995). https://doi.org/10.1557/jmr.1995.2085

M. Mori, J. Electrochem. Soc. 152, A732 (2005). https://doi.org/10.1149/1.1864312

L. Hamzioui, F. Kahoul, A.J.E.P. Boutarfaia, Energy Procedia J 74, 198 (2015). https://doi.org/10.1016/j.egypro.2015.07.577

F. Vasiliu, S. Moisa, D. Grozea, C. Bunescu, J. Mater. Sci. 29, 3337 (1994). https://doi.org/10.1007/bf00356682

F. Shi, J. Yang, Q. Liu, Z.M. Qi, H.Q. Sun, Mater. Chem. Phys. 200, 9 (2017). https://doi.org/10.1016/j.matchemphys.2017.06.059

Z. Wang, H.N. Chen, T. Wang, Y.J. Xiao, W.W. Nian, J.H. Fan, J. Eur. Ceram. Soc. 38, 3847 (2018). https://doi.org/10.1016/j.jeurceramsoc.2018.04.026

J. Sheen, Z.W. Hong, C.W. Su, H.C. Chen, Prog. Electromagn. Res. 100, 13 (2010). https://doi.org/10.2528/pier09091706

R. Muhammad, Y. Iqbal, J. Mater. Sci. 51, 2958 (2016). https://doi.org/10.1007/s10853-015-9604-x

E.S. Kim, S.J. Kim, Ferroelectrics 388, 93 (2009). https://doi.org/10.1080/00150190902965661

W.S. Kim, J.H. Kim, J.H. Kim, K.H. Hur, J.Y. Lee, Mater. Chem. Phys. 79, 204 (2003). https://doi.org/10.1016/s0254-0584(02)00267-5

F. Gheorghiu, L. Padurariu, M. Airimioaei, L. Curecheriu, C. Ciomaga, C. Padurariu, C. Galassi, L. Mitoseriu, J. Am. Ceram. Soc. 100, 647 (2017). https://doi.org/10.1111/jace.14587

C.L. Zhao, J.G. Wu, A.C.S. Appl, Mater. Interfaces. 10, 3680 (2018). https://doi.org/10.1021/acsami.7b18356

W. Cai, C.L. Fu, J.C. Gao, X.Y. Chen, Q.A. Zhang, Integr. Ferroelectr. 113, 83 (2009). https://doi.org/10.1080/10584581003785393

L.Y. Shen, M.J. Liu, X.Z. Liu, B. Li, Mater. Res. Bull. 42, 2048 (2007). https://doi.org/10.1016/j.materresbull.2007.02.001

W.R. Manning, O. Hunter, F.W. Calderwood, D.W. Stacy, J. Am. Ceram. Soc. 55, 342 (2010). https://doi.org/10.1111/j.1151-2916.1972.tb11306.x

Acknowledgements

This work was financed by Priority Academic Program Development of Jiangsu Higher Education Institutions (PAPD), the National Natural Science Foundation of China (Grant No. 52102089), and Key Research and Development Program of Zhejiang Province (Grant No. 2020C0112, 2021C01092)

Funding

This work was financed by Priority Academic Program Development of Jiangsu Higher Education Institutions (PAPD), the National Natural Science Foundation of China (Grant No. 52102089), and Key Research and Development Program of Zhejiang Province (Grant Nos. 2020C0112, 2021C01092).

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. XZ and CL contributed to the conception of this study, performed the experiment, analyzed the data, and wrote the manuscript. YL, YS, XL, QX, and HZ help perform the analysis with constructive discussions. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflicts of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Ethics approval

Not applicable.

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhang, X., Li, C., Lu, Y. et al. Microstructure and microwave dielectric properties of multi-oxide-doped (Zr, Sn)TiO4 ceramics. J Mater Sci: Mater Electron 33, 22153–22161 (2022). https://doi.org/10.1007/s10854-022-08994-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-022-08994-0