Abstract

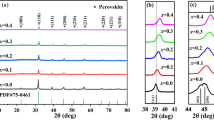

Mg doped (Ba0.98Li0.02)TiO3 energy storage ceramics with antiferroelectric-like double hysteresis loops were prepared using solid-state reaction method. XRD patterns indicated that tetragonal phase structure of the pure (Ba0.98Li0.02)TiO3 ceramic was destroyed and the orthorhombic phase structure appeared with Mg doping. The ratio of orthorhombic/tetragonal phase increased with Mg content increasing, and the value of polarization was in direct proportion to the ratio of orthorhombic/tetragonal phase. The breakdown strength of (Ba0.98Li0.02)(MgxTi1−x)O3 ceramics was improved from 60.97 kV/cm at x = 0 to 103.66 kV/cm at x = 0.04. The optimum energy storage properties of (Ba0.98Li0.02)(MgxTi1−x)O3 ceramics were obtained with energy storage density of 0.76 J/cm3 at 102.5 kV/cm when x = 0.04, which is nearly 2.3 times larger than the pure (Ba0.98Li0.02)TiO3 ceramic, and the energy storage efficiency was improved from 64 to 87%.

Similar content being viewed by others

Data availability

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

D. Lee, Energy Focus. (2016). https://doi.org/10.1016/j.ref.2016.02.013

H. Qi, A. Xie, A. Tian, R. Zuo, Adv. Eng. Mater. (2019). https://doi.org/10.1002/aenm.201903338

Z.H. Yao, Z. Song, H. Hua, Z.Y. Yu, M.H. Cao, S.J. Zhang, M.T. Lanagan, H.X. Liu, Adv. Mater. (2017). https://doi.org/10.1002/adma.201601727

W. Tuichai, N. Thongyong, S. Danwittayakul, N. Chanlek, P. Srepusharawoot, P. Thongbai, S. Maensiri, Mater. Des. (2017). https://doi.org/10.1016/j.matdes.2017.03.037

Z. Pan, D. Hu, Y. Zhang, J. Liu, B. Shen, J. Zhai, J. Mater. Chem. C (2019). https://doi.org/10.1039/c9tc00087a

Y. Zhang, S. Gao, H. Xing, J. Alloys Compd. (2019). https://doi.org/10.1016/j.jallcom.2018.10.378

L. Zhang, Y. Pu, M. Chen, T. Wei, X. Peng, Chem. Eng. J. (2020) https://doi.org/10.1016/j.cej.2019.123154

T.Q. Shao, H.L. Du, H. Ma, S.B. Qu, J. Wang, J.F. Wang, X.Y. Wei, Z. Xu, J. Mater. Chem. A (2017). https://doi.org/10.1039/C6TA07803F

Q.B. Yuan, F.Z. Yao, Y.F. Wang, R. Ma, H. Wang, J. Mater. Chem. C. (2017) https://doi.org/10.1039/C7TC02478A

Q.Y. Hu, Y. Tian, Q.S. Zhu, J.H. Bian, L. Jin, H.L. Du, D.O. Alikin, VYa. Shur, Y.J. Feng, Z. Xu, X.Y. Wei, Nano Energy (2020). https://doi.org/10.1016/j.nanoen.2019.104264

Z. Liu, T. Lu, J. Ye, G. Wang, X. Dong, R. Withers, Y. Liu, Adv. Mater. Technol. (2018) https://doi.org/10.1002/admt.201800111

H.R. Jo, C.S. Lynch, J. Appl. Phys. (2016) https://doi.org/10.1063/1.4939617

M.D. Nguyen, G. Rijinders, J. Eur. Ceram. Soc. (2018) https://doi.org/10.1016/j.jeurceramsoc.2018.07.026

Y. Xu, G. Wang, Y. Tian, X. Liu, Y. Feng, Ceram. Int. (2016) https://doi.org/10.1016/j.ceramint.2016.09.021

Y.H. Xu, Y. Guo, Q. Liu, G.D. Wang, J.L. Bai, J.J. Tian, L. Lin, Y. Tian, J. Eur. Ceram. Soc. (2020) https://doi.org/10.1016/j.jeurceramsoc.2019.09.022

L. Zhao, J. Gao, Q. Liu, S.J. Zhang, J.F. Li, ACS Appl. Mater. Interfaces (2018). https://doi.org/10.1021/acsami.7b17382

P.R. Rena, D. Ren, L. Sun, F.X. Yan, S. Yang, G.Y. Zhao, J. Eur. Ceram. Soc. (2020) https://doi.org/10.1016/j.jeurceramsoc.2020.05.076

J. Gao, L. Zhao, Q. Liu, X. Wang, S. Zhang, J.F. Li, J. Am. Ceram. Soc. (2018) https://doi.org/10.1111/jace.15780

K. Yan, F.F. Wang, D.W. Wu, X.B. Ren, K.J. Zhu, J. Am. Ceram. Soc. (2019) https://doi.org/10.1111/jace.16117

W.W. Ping, W.F. Liu, S.T. Li, Ceram. Int. (2019) https://doi.org/10.1016/j.ceramint.2019.03.003

T. Wang, L. Jin, C. Li, Q. Hu, X. Wei, D. Lupascu, J. Am. Ceram. Soc. (2015) https://doi.org/10.1111/jace.13325

X. Ren, Nat. Mater. (2004) https://doi.org/10.1038/nmat1051

W.F. Liu, J.H. Gao, Y. Zhao, S.T. Li, J. Alloys Compd. (2020) https://doi.org/10.1016/j.jallcom.2020.155938

M. Wei, J.H. Zhang, K.T. Wu, H.W. Chen, C.R. Yang, Ceram. Int. (2017) https://doi.org/10.1016/j.ceramint.2017.03.139

G. Liu, Y. Li, B. Guo, M.Y. Tang, Q. Li, J. Dong, L.J. Yu, K. Yu, Y. Yan, D.W. Wang, L.Y. Zhang, H.B. Zhang, Z.B. He, L. Jin, Chem. Eng. J. (2020) https://doi.org/10.1016/j.cej.2020.125625

C. Wang, F. Yan, H. Yang, Y. Lin, T. Wang, J. Alloy Compd. (2018) https://doi.org/10.1016/j.jallcom.2018.03.195

W.M. Xia, N. Zhang, H.X. Yang, C.J. Cao, J.L. Li, J. Alloy Compd. (2019) https://doi.org/10.1016/j.jallcom.2019.02.332

C.L. Diao, H.X. Liu, H. Hao, M.H. Cao, Z.H. Yao, Ceram. Int. (2016) https://doi.org/10.1016/j.ceramint.2016.04.169

G.W. Yan, M.G. Ma, C.B. Li, Z.W. Li, X.Y. Zhong, J. Yang, F. Wu, Z.H. Chen, J. Alloy Compd. (2021) https://doi.org/10.1016/j.jallcom.2020.158021

N. Huang, H.X. Liu, H. Hao, Z.H. Yao, M.H. Cao, J. Xie, Ceram. Int. (2019) https://doi.org/10.1016/j.ceramint.2019.04.227

G. Liu, J. Dong, L.Y. Zhang, L.J. Yu, F.B. Wei, Y. Li, J.H. Gao, J.Z. Hu, Y. Yan, Q. Li, K. Yu, L. Jin, Ceram. Int. (2020) https://doi.org/10.1016/j.ceramint.2020.01.199

Y.T. Lin, S.F. Ou, M.H. Lin, Y.R. Song, Ceram. Int. (2018) https://doi.org/10.1016/j.ceramint.2017.10.155

H. Hayashi, H. Inaba, M. Matsuyama, N.G. Lan, M. Dokiya, H. Tagawa, Solid State Ionics (1999) https://doi.org/10.1016/S0167-2738(99)00066-1

M.T. Yao, Y.P. Pu, H.Y. Zheng, L. Zhang, M. Chen, Y.F. Cui, Ceram. Int. (2016) https://doi.org/10.1016/j.ceramint.2016.02.155

P. Ren, Q. Wang, S. Li, G. Zhao, J. Eur. Ceram. Soc. (2017) https://doi.org/10.1016/j.jeurceramsoc.2016.12.016

H.B. Yang, F. Yan, Y. Lin, T. Wang, L. He, F. Wang, J. Alloy Compd. (2017) https://doi.org/10.1016/j.jallcom.2017.03.261

Z.L. Lu, W.C. Bao, G. Wang, S.K. Suan, L.H. Li, J.L. Li, H.J. Yang, H.F. Ji, A. Feteira, D.J. Li, F.F. Xu, A.K. Kleppe, D.W. Wang, S.Y. Liu, I.M. Reaney, Nano Energy (2021) https://doi.org/10.1016/j.nanoen.2020.105423

W. Cai, C.L. Fu, J.C. Gao, C.X. Zhao, Adv. Appl. Ceram. (2011). https://doi.org/10.1179/1743676110Y.0000000019

M.X. Zhou, R.H. Liang, Z.Y. Zhou, X.L. Dong, Ceram. Int. (2019) https://doi.org/10.1016/j.ceramint.2018.11.018

S.X. Xue, S.H. Liu, W.Q. Zhang, J.W. Zhang, J.W. Wang, L.J. Tang, B. Shen, J.W. Zhai, J. Alloy Compd. (2014) https://doi.org/10.1016/j.jallcom.2014.08.006

X.C. Wang, W.Q. Cai, Z. Xiao, G.G. Yang, X.M. Yu, J.W. Chen, D.C. Chen, Q.F. Zhang, M. Chen, J. Eur. Ceram. Soc. (2021) https://doi.org/10.1016/j.jeurceramsoc.2021.04.030

M. Xu, B. Peng, J. Zhu, L. Liu, W. Sun, G.J.T. Leighton, C. Shaw, N. Luo, Q. Zhang, J. Alloy Compd. (2019) https://doi.org/10.1016/j.jallcom.2019.02.314

Y.Y. Guo, M.J. Liu, Y.F. Guo, T. Wei, Y.J. Guo, N. Zhang, AIP Adv. (2015). https://doi.org/10.1063/1.4930259

G. Liu, Y. Li, J.H. Gao, D.Q. Li, L.J. Yu, J. Dong, Y.T. Zhang, Y. Yan, B.Y. Fan, X.Y. Liu, L. Jin, J. Alloy Compd. (2020) https://doi.org/10.1016/j.jallcom.2020.154160

R. Machado, A. Di Loreto, A. Frattini, M. Sepliarsky, M.G. Stachiotti, J. Alloy Compd. (2019) https://doi.org/10.1016/j.jallcom.2019.151847

Funding

This work was supported by (National Natural Science Foundation of China) [Grant No. (51702024)].

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation, data collection and analysis were performed by GY, QL, BF and ZC. The first draft of the manuscript was written by GY and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding authors

Ethics declarations

Conflict of interest

The authors have no relevant financial or non-financial interests to disclose.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Yan, Gw., Liu, Qq., Fang, Bj. et al. Correlation between phase structure and polarization of Mg doped (Ba0.98Li0.02)TiO3 energy storage ceramics. J Mater Sci: Mater Electron 33, 20981–20991 (2022). https://doi.org/10.1007/s10854-022-08903-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-022-08903-5