Abstract

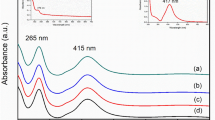

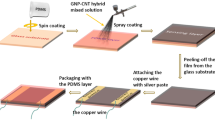

Flexible and stretchable strain sensors are getting vast attention to be implied in various wearable devices application. However, most conventional strain sensor is having limitations in achieving both high stretchability and sensitivity. Selection of materials for conductive fillers and binders are crucial in producing the stretchable ink for strain sensors. Biopolymer materials such as chitosan started to be implied in various application such as gas sensor and electrochemical sensor. Chitosan has advantages to be a good binder as it exerts significant physical properties. Conductive fillers such as graphite powder are known to be having good electrical conductivity. Hence, this paper aims to investigate the effect of different graphite/chitosan ink ratio composition towards flexible and stretchable strain sensor performance. Three different graphite/chitosan ink ratios of 1:2, 1:3, and 1:4 were synthesized. The surface morphology shows that the graphite/chitosan ink ratio 1:2 has the most compact structure resulting to good adaptability, conductivity, and flexibility. The XRD and FTIR results illustrate that graphite are successfully synthesized with chitosan solution. Measurement result shows that the highest strain detection range is also attainable by graphite/chitosan ink ratio of 1:2 at 83.3% strain and gauge factor of 5.44. This concludes that graphite/chitosan ink ratio of 1:2 is the optimum ratio as highest stretchability and sensitivity are recorded. Therefore, it is important to have an adequate amount of chitosan solution to obtain good ink structure and great performance of strain sensor.

Similar content being viewed by others

Data availability

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

X. Liu et al., Overview of spintronic sensors with internet of things for smart living. IEEE Trans. Magn. (2019). https://doi.org/10.1109/TMAG.2019.2927457

A.A. Rifat et al., Photonic crystal fiber based plasmonic sensors. Sens. Actuators B 243(November), 311–325 (2017). https://doi.org/10.1016/j.snb.2016.11.113

J. Ge et al., A stretchable electronic fabric artificial skin with pressure-, lateral strain-, and flexion-sensitive properties. Adv. Mater. 28(4), 722–728 (2016). https://doi.org/10.1002/adma.201504239

T. Yang, D. Xie, Z. Li, H. Zhu, Recent advances in wearable tactile sensors: Materials, sensing mechanisms, and device performance. Mater. Sci. Eng. R 115, 1–37 (2017). https://doi.org/10.1016/j.mser.2017.02.001

K. Senthil Kumar, P.-Y. Chen, H. Ren, A review of printable flexible and stretchable tactile sensors. Research 2019, 1–32 (2019). https://doi.org/10.34133/2019/3018568

Q. Li et al., Engineering of carbon nanotube/polydimethylsiloxane nanocomposites with enhanced sensitivity for wearable motion sensors. J. Mater. Chem. C 5(42), 11092–11099 (2017). https://doi.org/10.1039/c7tc03434b

S. Gong et al., Highly stretchy black gold E-skin nanopatches as highly sensitive wearable biomedical sensors. Adv. Electron. Mater. 1(4), 1–7 (2015). https://doi.org/10.1002/aelm.201400063

W. Tang, T. Yan, J. Ping, J. Wu, Y. Ying, Rapid fabrication of flexible and stretchable strain sensor by chitosan-based water ink for plants growth monitoring. Adv. Mater. Technol. 2(7), 1–5 (2017). https://doi.org/10.1002/admt.201700021

W. Tang et al., Rapid fabrication of wearable carbon nanotube/graphite strain sensor for real-time monitoring of plant growth. Carbon N. Y. 147, 295–302 (2019). https://doi.org/10.1016/j.carbon.2019.03.002

J. Kim, R. Kumar, A.J. Bandodkar, J. Wang, Advanced materials for printed wearable electrochemical devices: a review. Adv. Electron. Mater. 3(1), 1–15 (2017). https://doi.org/10.1002/aelm.201600260

J.Z. Gul, M. Sajid, K.H. Choi, 3D printed highly flexible strain sensor based on TPU-graphene composite for feedback from high speed robotic applications. J. Mater. Chem. C 7(16), 4692–4701 (2019). https://doi.org/10.1039/c8tc03423k

J.J. Park, W.J. Hyun, S.C. Mun, Y.T. Park, O.O. Park, Highly stretchable and wearable graphene strain sensors with controllable sensitivity for human motion monitoring. ACS Appl. Mater. Interfaces 7(11), 6317–6324 (2015). https://doi.org/10.1021/acsami.5b00695

Y. Liu, H. Zheng, M. Liu, High performance strain sensors based on chitosan/carbon black composite sponges. Mater. Des. 141, 276–285 (2018). https://doi.org/10.1016/j.matdes.2017.12.046

C. Mattmann, F. Clemens, G. Tröster, Sensor for measuring strain in textile. Sensors 8(6), 3719–3732 (2008). https://doi.org/10.3390/s8063719

M. Mohammed Ali et al., Printed strain sensor based on silver nanowire/silver flake composite on flexible and stretchable TPU substrate. Sens. Actuators A 274, 109–115 (2018). https://doi.org/10.1016/j.sna.2018.03.003

M. Hu, X. Cai, Q. Guo, B. Bian, T. Zhang, J. Yang, Direct pen writing of adhesive particle-free ultrahigh silver salt-loaded composite ink for stretchable circuits. ACS Nano 10(1), 396–404 (2016). https://doi.org/10.1021/acsnano.5b05082

A.J. Bandodkar, R. Nuñez-Flores, W. Jia, J. Wang, All-printed stretchable electrochemical devices. Adv. Mater. 27(19), 3060–3065 (2015). https://doi.org/10.1002/adma.201500768

R. Ma, B. Kang, S. Cho, M. Choi, S. Baik, Extraordinarily high conductivity of stretchable fibers of polyurethane and silver nanoflowers. ACS Nano 9(11), 10876–10886 (2015). https://doi.org/10.1021/acsnano.5b03864

J.Y. Je, S.K. Kim, Chitosan as Potential Marine Nutraceutical, 1st edn. (Elsevier Inc., Amsterdam, 2012)

J. Park, I. You, S. Shin, U. Jeong, Material approaches to stretchable strain sensors. ChemPhysChem 16(6), 1155–1163 (2015). https://doi.org/10.1002/cphc.201402810

M. Balyan, T.I. Nasution, I. Nainggolan, H. Mohamad, Z.A. Ahmad, Energy harvesting properties of chitosan film in harvesting water vapour into electrical energy. J. Mater. Sci. Mater. Electron. 30(17), 16275–16286 (2019). https://doi.org/10.1007/s10854-019-01998-3

M.M. Ayad, I.M. Minisy, Detection and kinetics of methylamine on chitosan film coated quartz crystal microbalance electrode. Prog. Org. Coatings 100, 76–80 (2016). https://doi.org/10.1016/j.porgcoat.2016.01.012

M.T. Yen, J.H. Yang, J.L. Mau, Physicochemical characterization of chitin and chitosan from crab shells. Carbohydr. Polym. 75(1), 15–21 (2009). https://doi.org/10.1016/j.carbpol.2008.06.006

E. Chorbadzhiyska, I. Bardarov, Y. Hubenova, M. Mitov, Graphite–metal oxide composites as potential anodic catalysts for microbial fuel cells. Catalysts 10(7), 1–14 (2020). https://doi.org/10.3390/catal10070796

A.H. Gedam, R.S. Dongre, A.K. Bansiwal, Synthesis and characterization of graphite doped chitosan composite for batch adsorption of lead(II) ions from aqueous solution. Adv. Mater. Lett. 6(1), 59–67 (2015). https://doi.org/10.5185/amlett.2015.7592

A.A. Dubale et al., The synergetic effect of graphene on Cu2O nanowire arrays as a highly efficient hydrogen evolution photocathode in water splitting. J. Mater. Chem. A 2(43), 18383–18397 (2014). https://doi.org/10.1039/c4ta03464c

M. Ali, Raman Characterization of Structural Properties of Thermally Modified Nanographite. vol. Independen, p. 49, 2015

Acknowledgements

This work is fully supported by the Ministry of Higher Education (MOHE) Fundamental Research Grant Scheme (FRGS 21-249-0858) (Grant No: FRGS/1/2021/TK0/UIAM/02/14).

Funding

This work is fully supported by the Ministry of Higher Education (MOHE) Fundamental Research Grant Scheme (FRGS 21-249-0858) (Grant No: FRGS/1/2021/TK0/UIAM/02/14).

Author information

Authors and Affiliations

Contributions

The authors confirm the contribution as follows: study and idea conception and design: AAMR Synthesis, characterization and measurements: NIIMH Analysis and interpretation of results AAMR, NIIMH, FBA, MAbMH Draft Manuscript preparation: NIIMH in consultation with AAMR, FBA and MAbMH. Supervised the findings of the project: AAMR All authors discussed the results and contributed to the final manuscript, reviewed the results and approved the final version of the manuscript. All authors whose names appear on the submission: made substantial contributions to the conception or design of the work; or the acquisition, analysis, or interpretation of data; or the creation of new software used in the work; drafted the work or revised it critically for important intellectual content; approved the version to be published; and agree to be accountable for all aspects of the work in ensuring that questions related to the accuracy or integrity of any part of the work are appropriately investigated and resolved.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Ethical approval

All authors certify that they have no affiliations with or involvement in any organization or entity with any financial interest or non-financial interest in the subject matter or materials discussed in this manuscript.

Research involving human and animal rights

The authors declare that this research does not contain any studies involving human participants and/or animals.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Maizal Hairi, N.I.I., Md Ralib, A.A., Ahmad, F.B. et al. Synthesis and characterization of different graphite/chitosan ink ratio composition towards flexible strain sensor performance. J Mater Sci: Mater Electron 33, 15574–15585 (2022). https://doi.org/10.1007/s10854-022-08463-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-022-08463-8