Abstract

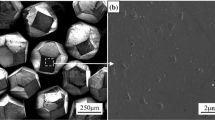

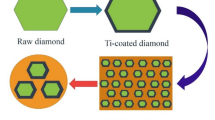

Molybdenum (Mo) coating was deposited on the diamond surface by vacuum micro-vapor deposition. Effects of deposition parameters on the formation of Mo coating on the diamond different crystal face was investigated. The mechanism of diamond metallization evolution, fracture mode and thermal conductivity of diamond/copper composites were discussed. It is shown that the coating of diamond particles is starting with point-like particles grew up to be continuous, dense spherical coating, and the compactness of the coating on diamond <100> facet always takes precedence over diamond <111> facet. The Mo coating on the diamond surface deposited at 1050 °C for 50 min shows the best quality. The fracture modes of Mo-coated diamond/copper composites are composed of diamond debonding from copper matrix, diamond transgranular fracture and copper ductile fracture, but some pores existed at the interfere, it concludes that the Mo2C prepare a Cu/Mo/diamondinterlayer between the diamond and copper matrix could improve the bonding between diamond and copper matrix, but the effect of Mo2C coating on strengthen the interfacial bonding is limited. The highest thermal conductivity of the composites achieved the value of 329 W/(m K).

Similar content being viewed by others

Data availability

All data available.

References

S. Mallik, N. Ekere, C. Best, R. Bhatti, Investigation of thermal management materials for automotive electronic control units. Appl. Therm. Eng. 31(2–3), 355–362 (2011)

L. Weber, R. Tavangar, On the influence of active element content on the thermal conductivity and thermal expansion of Cu–X (X = Cr, B) diamond composites. Scripta. Mater. 57(11), 988–991 (2007)

M. Wu, C.Z. Cao, U.D. Rafi, X.B. He, X.H. Qu, Brazing diamond/Cu composite to alumina using reactive Ag–Cu–Ti alloy. Trans. Nonferrous Met. Soc. China 23(06), 1701–1708 (2013)

M.H. Chen, H.Z. Li, C.R. Wang, N. Wang, Z.Y. Li, L.N. Tang, Progress in heat conduction of diamond/Cu composites with high thermal conductivity. Rare Met. Mater. Eng. 49(12), 4146–4158 (2020)

Y.H. Dong, R.Q. Zhang, X.B. He, Z.G. Ye, X.H. Qu, Fabrication and infiltration kinetics analysis of Ti-coated diamond/copper composites with near-net-shape by pressureless infiltration. Mater. Sci. Eng. 177(17), 1524–1530 (2012)

B. Shen, S.L. Chen, F.H. Sun, Effect of deposition temperature on properties of boron-doped diamond films on tungsten carbide substrate. Trans. Nonferrous Met. Soc. China 28(4), 729–738 (2018)

J.M. Tao, X.K. Zhu, W.W. Tian, P. Yang, H. Yang, Properties and microstructure of Cu/diamond composites prepared by spark plasma sintering method. Trans. Nonferrous Met. Soc. China 24(10), 3210–3214 (2014)

J.H. Jia, S.X. Bai, D.G. Xiong, J. Wang, J. Chang, Effect of tungsten based coating characteristics on microstructure and thermal conductivity of diamond/Cu composites prepared by pressueless infiltration. Ceram. Int. 45(8), 10810–10818 (2019)

S.D. Ma, N.Q. Zhao, C.S. Shi, E.Z. Liu, C.N. He, F. He, L.Y. Ma, Mo2C, Coating on diamond: different effects on thermal conductivity of diamond/Al and diamond/Cu composites. Appl. Surf. Sci. 402, 372–383 (2017)

A.M. Abyzov, M.J. Kruszewski, Ł Ciupiński, M. Mazurkiewicz, A. Michalski, K.J. Kurzydłowski, Diamond–tungsten based coating-copper composites with high thermal conductivity produced by Pulse Plasma Sintering. Mater. Des. 76, 97–109 (2015)

J. Grzonka, M.J. Kruszewski, M. Rosiński, L. Ciupiński, A. Michalski, K.J. Kurzydłowski, Interfacial microstructure of copper/diamond composites fabricated via a powder metallurgical route. Mater. Charact. 99, 188–194 (2015)

J.W. Li, X.T. Wang, Y. Qiao, Y. Zhang, Z.B. He, H.L. Zhang, High thermal conductivity through interfacial layer optimization in diamond particles dispersed Zr-alloyed Cu matrix composites. Scr. Mater. 109, 72–75 (2015)

L. Ciupiński, M.J. Kruszewski, J. Grzonka, M. Chmielewski, R. Zielińsk, D. Moszczyńska, A. Michalski, Design of interfacial Cr3C2 carbide layer via optimization of sintering parameters used to fabricate copper/diamond composites for thermal management applications. Mater. Des. 120, 170–185 (2017)

Q.P. Kang, X.B.S.B. HERen, L. Zhang, M. Wu, C.Y. Guo, Q. Liu, T.T. Liu, X.H. Qu, Effect of molybdenum carbide intermediate layers on thermal properties of copper–diamond composites. J. Alloys Compd. 576, 380–385 (2013)

S. Nezamdoust, D. Seifzadeh, A. Habibi-Yangjeh, Nano-diamond incorporated sol–gel coating for corrosion protection of magnesium alloy. Trans. Nonferrous Met. Soc. China 30(06), 1535–1549 (2020)

W.M. Daoush, H.S. Park, S.H. Hong, Fabrication of TiN/cBN and TiC/diamond coated particles by titanium deposition process. Trans. Nonferrous Met. Soc. China 24(11), 3562–3570 (2014)

Y.F. Zhu, L. Wang, W.Q. Yao, L.L. Cao, The interface diffusion and reaction between Cr layer and diamond particle during metallization. Appl. Surf. Sci. 171(1–2), 143–150 (2001)

C.R. Wang, W.Tian, J.S. Hu, B. Li, P.C. Li, T.S. Lin, W.H. Liao, Magnetron sputtering coating and heat treatment process of diamond copper particles. Trans. Nonferrous Met. Soc. (2021)

X.Y. Shen, X.B. He, S.B. Ren, H.M. Zhang, X.H. Qu, Effect of molybdenum as interfacial element on the thermal conductivity of diamond/Cu composites. J. Alloys Compd. 529, 134–139 (2012)

T. Okada, K. Fukuoka, Y. Arata, S. Yonezawa, H. Kiyokawa, M. Takashima, Tungsten carbide coating on diamond particles in molten mixture of Na2CO3 and NaCl. Diam. Relat. Mater. 52, 11–17 (2015)

A.M. Abyzov, S.V. Kidalov, F.M. Shakhov, High thermal conductivity composites consisting of diamond filler with tungsten coating and copper (silver) matrix. J. Mater. Sci. 46(5), 1424–1438 (2011)

A.V. Ukhina, D.V. Dudina, M.A. Esikov, D.A. Samoshkin, S.V. Stankus, I.N. Skovorodin, E.N. Galashov, B.B. Bokhonov, The influence of morphology and composition of metal–carbide coatings deposited on the diamond surface on the properties of copper–diamond composites. Surf. Coat. Technol. 401, 126272 (2020)

R.X. Liu, G.Q. Luo, Y. Li, J. Zhang, Q. Shen, L.M. Zhang, Microstructure and thermal properties of diamond/copper composites with Mo2C in-situ nano-coating. Surf. Coat. Technol. 360, 376–381 (2019)

G. Chang, F.Y. Sun, L.H. Wang, Y. Zhang, X.T. Wang, J.G. Wang, M.J. Kim, H.L. Zhang, Mo-interlayer-mediated thermal conductance at Cu/diamond interface measured by time-domain thermoreflectance. Compos. 135, 105921 (2020)

T. Long, The effect of constructing interface on microstructure and thermal conductivity of diamond/copper composites for thermal management. Nanchang Hangkong University. (2014)

M.H. Hu, K.P. Yu, N. Bi, S.S. Li, T.C. Su, Q. Hu, Effect of diamond size on properties of particles reinforced diamond/Cu composites. J. Funct. Mater. 49(1), 1059–1063 (2018)

H. Chen, C.C. Jia, S.J. Li, X. Jia, X. Yang, Selective interfacial bonding and thermal conductivity of diamond/Cu-alloy composites prepared by HPHT technique. Int. J. Miner. Met. Mater. 19(4), 364–371 (2012)

E.A. Ekimov, N.V. Suetin, A.F. Popovich, V.G. Ralchenko, Thermal conductivity of diamond composites sintered under high pressures. Diam. Relat. Mater. 17(4–5), 838–843 (2008)

H.D. Zhang, Y. Liu, F. Zhang, D. Zhang, H.X. Zhu, T.X., Fan, Hot deformation behavior and processing maps of diamond/Cu composites. Metall. Mater. Trans. A 49(6), 1–11 (2018)

K. Hanada, K. Matsuzaki, T. Sano, Thermal properties of diamond particle-dispersed Cu composites. J. Mater. Process. Technol. 153–154, 514–518 (2004)

C. Zhang, R.C. Wang, Z.Y. Cai, C.Q. Peng, N.G. Wang, Low-temperature densification of diamond/Cu composite prepared from dual-layer coated diamond particles. Mater. Sci. 26(1), 185–190 (2015)

Q.L. Che, J.J. Zhang, X.K. Chen, Y.Q. Ji, Y.W. Li, L.X. Wang, S.Z. Cao, L. Guo, Z. Wang, S.W. Wang, Z.K. Zhang, Y.G. Jiang, Spark plasma sintering of titanium-coated diamond and copper–titanium powder to enhance thermal conductivity of diamond/copper composites. Mater. Sci. Semicond. Process. 33, 67–75 (2015)

Y.D. Igorevich, S.A. Vladimirovich, S.P.N. Washington, P.P. Yurevich, T.S.M. Ramon, Modeling process of spark plasma sintering of powder materials by finite element method. Mater. Sci. Forum 834, 10 (2015)

K. Chu, Z.F. Liu, C.C. Jia, H. Chen, X.B. Liang, W.J. Gao, W.H. Tian, H. Guo, Thermal conductivity of SPS consolidated Cu/diamond composites with Cr-coated diamond particles. J. Alloys Compd. 529, 453–458 (2010)

H.Z. Li, C.R. Wang, L.M. Wu, C.M.H. Chen, C. Wu, N. Wang, Z.Y. Li, L.N. Tang, Q.L. Pang, Optimization of process parameters, microstructure, and thermal conductivity properties of Ti-coated diamond/copper composites prepared by spark plasma sintering. Mater. Sci. Mater. Electron. 32, 9115–9125 (2021)

R. Chang, J.B. Zang, Y.H. Wang, Y.Q. Yu, J. Lu, X.P. Xu, Preparation of the gradient Mo layers on diamond grits by spark plasma sintering and their effect on Fe-based matrix diamond composites. J. Alloys Compd. 695, 70–75 (2017)

M. Tokita, E. Bldg, K. Sc, P. Ksp, Mechanism of spark plasma sintering. Ceram. 21-22, 23–33 (1999)

Y.H. Dong, R.Q. Zhang, X.B. He, Z.G. YE, X.H. Qu, Fabrication and infiltration kinetics analysis of Ti-coated diamond/copper composites with near-net-shape by pressureless infiltration. Mater. Sci. Eng. B 177, 1524–1530 (2012)

L. Yang, L. Sun, W.W. Bai, L.C. Li, Thermal conductivity of Cu–Ti/diamond composites via spark plasma sintering. Diam. Relat. Mater. 94, 37–42 (2019)

C.D. Wagner, A.V. Naumkin, A. Kraut-Vass, J.W. Allison, C.J. Powell, J. R. Rumble Jr., NIST Standard Reference Database 20, in: NIST XPS Database Version, vol. 3 (2003)

Y.P. Pan, X.B. He, S.B. Ren, M. Wu, X.H. Qu, Optimized thermal conductivity of diamond/Cu composite prepared with tungsten-copper-coated diamond particles by vacuum sintering technique. Vacuum 153, 74–81 (2018)

Q.L. Che, X.K. Chen, Y.Q. Ji, Y.W. Li, L.X. Wang, S.Z. Cao, Y.G. Jiang, Z. Wang, The influence of minor titanium addition on thermal properties of diamond/copper composites via in situ reactive sintering. Mater. Sci. Semicond. Process. 30, 104–111 (2015)

N. Jiang, L.C. Wang, J.H. Won, M.H. Jeon, Y. Mori, A. Hatta, T. Ito, T. Sasaki, A. Hiraki, Interfacial analysis of CVD diamond on copper substrates. Diam. Relat. Mater. 6(5–7), 743–746 (1997)

W.Q. Qiu, Z.W. Liu, L.X. He, D.C. Zeng, Y.W. Mai, Improved interfacial adhesion between diamond film and copper substrate using a Cu (Cr)–diamond composite interlayer. Mater. Lett. 81, 155–157 (2012)

C.R. Wang, H.Z. Li, M.H. Chen, Z.Y. Li, L.N. Tang, Microstructure and thermo-physical properties of Cu–Ti double-layer coated diamond/Cu composites fabricated by spark plasma sintering. Diam. Relat. Mater. 109, 108041 (2020)

C. Zhang, R.C. Wang, Z.Y. Cai, C.Q. Peng, Y. Feng, L. Zhang, Effects of dual-layer coatings on microstructure and thermal conductivity of diamond/Cu composites prepared by vaccum hot pressing. Surf. Coat. Technol. 277, 99–307 (2015)

H.B. Hu, J. Kong, Improved thermal performance of diamond-vopper composites with boron carbide coating. J. Mater. Eng. Perform. 23(2), 651–657 (2014)

W.S. Williams, The thermal conductivity of metallic ceramics. JOM 50(6), 62–66 (1998)

E.T. Swartz, R.O. Pohl, Thermal boundary resistance. Reviews.Mod. Phys. 61, 605–620 (1989)

R.J. Stoner, H.J. Maris, Kapitza conductance and heat flow between solids at temperatures from 50 to 300 K. Phys. Rev. B 48(22), 16373 (1993)

Funding

This was supported by the National Natural Science Foundation of China (Grant No. 52075250), the China Postdoctoral Science Foundation (Grant No. 2020M683376) and State Key Laboratory of Advanced Welding and Joining, Harbin Institute of Technology (Grant No. AWJ-22M13), the Fundamental Research Funds for the Central Universities (Grant No. NT2021018).

Author information

Authors and Affiliations

Contributions

HL: done experiments and wrote the manuscript, CW: modified the structure of manuscript, WD: modified the grammar of manuscript and improved the English erros, TW, JH, CW and MC: guided and assisted the work of experiment, HZ, TL, WL modified the structure of manuscript, WD modified and improvd the overall quality of the manuscript.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported.

Ethical approval

The authors comply with ethical standard in this paper writing.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Li, H., Wang, C., Ding, W. et al. Microstructure evolution of diamond with molybdenum coating and thermal conductivity of diamond/copper composites fabricated by spark plasma sintering. J Mater Sci: Mater Electron 33, 15369–15384 (2022). https://doi.org/10.1007/s10854-022-08441-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-022-08441-0