Abstract

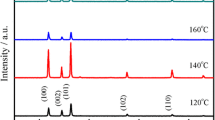

Thallium (Tl)-doped ZnO nanorods were prepared (the doping ratios were between 0 and 5 mol %) in two stages. Combined sol–gel and spin-coating methods and hydrothermal method were used, respectively. Depending on the concentrations of the Tl dopant, the structural, morphological, electrical, and optical properties of the samples were examined. XRD results demonstrated that the ZnO samples were in hexagonal (wurtzite) unit cell type with single crystalline nature. FE-SEM results indicated that the undoped and Tl-doped ZnO samples had hexagonal rod-like structures. The average lengths and diameters of the samples were between 0.90 and 1.35 μm, and 80 and 120 nm, respectively. The electrical conductivity increased with increasing temperature and doping concentrations. For the undoped and 5 mol % Tl-doped ZnO-samples, the electrical conductivity values were 1.22E−08 and 1.95E−05 (Ω.cm)−1 at 25 °C and 4.84E−07 and 3.97E−04 (Ω.cm)−1 at 300 °C, respectively. The 1 mol % Tl-doped ZnO had the highest transmittance (within the range of 70 and 80%) in the wavelength of between 500 and 1000 nm. The band gap energy values of the Tl-doped samples were higher than the undoped ZnO sample.

Similar content being viewed by others

Data availability

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

S. Sohn, Y. Soo Han, Transparent conductive oxide (TCO) films for organic light emissive devices (OLEDs) organic light emitting diode- material, process and devices. IntechOpen (2011). https://doi.org/10.5772/18545

M.A. Aouaj, R. Diaz, A. Belayachi, F. Rueda, M. Abd-Lefdil, Comparative study of ITO and FTO thin films grown by spray pyrolysis. Mater Res Bull 44, 1458–1461 (2009). https://doi.org/10.1016/j.materresbull.2009.02.019

Y. Liu, Y. Li, H. Zeng, ZnO-based transparent conductive thin films: doping, performance, and processing. J. Nanomater. (2013). https://doi.org/10.1155/2013/196521

H. Çolak, O. Türkoğlu, Studies on structural and electrical properties of copper-doped zinc oxide powders prepared by a solid state method at high temperatures. Mater. High Temp. 29, 344–350 (2012). https://doi.org/10.3184/096034012X13390873728509

V. Kumari, V. Kumar, B.P. Malik, R.M. Mehra, D. Mohan, D. Mohan, Nonlinear optical properties of erbium doped zinc oxide (EZO) thin films. Opt. Commun. 285, 2182–2188 (2012). https://doi.org/10.1016/J.OPTCOM.2011.12.094

F. Chaabouni, J.B. Belgacem, M. Abaab, Physical properties of TCO-ZnO thin films sputtered from a powder target. Chin. J. Phys. 52(1), 272–285 (2014). https://doi.org/10.1155/2015/936482

M. Kovalenko, O. Bovgyra, A. Franiv, V. Dzikovskyi, Electronic structure of ZnO thin films doped with group III elements. Mater. Today-Proc. 35, 604–608 (2019). https://doi.org/10.1016/j.matpr.2019.11.274

R. Hofstadter, Alkali halide scintillation counters. Phys. Rev. 74, 100–101 (1948). https://doi.org/10.1103/PhysRev.74.100

N. Huang, M.W. Zhu, L.J. Gao, J. Gong, C. Sun, X. Jiang, A template-free sol–gel technique for controlled growth of ZnO nanorod arrays. Appl. Surf. Sci. 257, 6026–6033 (2011). https://doi.org/10.1016/j.apsusc.2011.01.112

K. Ogata, K. Maejima, F. Sz, S.G. Fujita, Growth mode control of ZnO toward nanorod structures or high-quality layered structures by metal-organic vapor phase epitaxy. J. Cryst. Growth 248, 25–30 (2003). https://doi.org/10.1016/S0022-0248(02)01843-2

J.J. Wu, S.C. Liu, Low-temperature growth of well-aligned ZnO nanorods by chemical vapor deposition. Adv. Mater. 14, 215–218 (2002). https://doi.org/10.1002/1521-4095

J. Zhao, L. Qin, L. Zhang, Synthesis of quasi-aligned Si-doped ZnO nanorods on Si substrate. Physica E 40, 795–799 (2008). https://doi.org/10.1016/j.physe.2007.10.057

L. Vayssieres, Growth of arrayed nanorods and nanowires of ZnO from aqueous solutions. Adv. Mat. 15, 464–466 (2003). https://doi.org/10.1002/adma.200390108

P.N. Mbuyisa, O.M. Ndwandwe, C. Cepek, Controlled growth of zinc oxide nanorods synthesized by the hydrothermal method. Thin Solid Films 578, 7–10 (2015). https://doi.org/10.1016/j.tsf.2015.02.002

L.W. Brooks, J.M. Mativetsky, A. Woll, D. Smilgies, Y.L. Loo, Sputtered ZnO seed layer enhances photovoltaic behavior in hybrid ZnO/P3HT solar cells. Org. Electron. (2013). https://doi.org/10.1016/j.orgel.2013.09.023

S.Y. Pung, K.L. Choy, H.X. Shan, C, Preferential growth of ZnO thin films by the atomic layer deposition technique. Nanotechnology (2008). https://doi.org/10.1088/0957-4484/19/43/435609

S. Saini, P. Mele, H. Honda, T. Suzuki, K. Matsumoto, K. Miyazaki, A. Ichinose, L.M. Luna, R. Carlini, A. Tiwari, Effect of self-grown seed layer on thermoelectric properties of ZnO thin films. Thin Solid Films 605, 289–294 (2016). https://doi.org/10.1016/j.tsf.2015.09.060

H.G. Chen, Z.W. Li, Seed-assisted growth of epitaxial ZnO nanorod arrays with self-organized periodicity and directional alignment. Appl. Surf. Sci. 258, 556–564 (2011). https://doi.org/10.1016/j.apsusc.2011.08.069

J. Zhang, W. Que, Preparation and characterization of sol–gel Al-doped ZnO thin films and ZnO nanowire arrays grown on Al-doped ZnO seed layer by hydrothermal method. Sol. Energ. Mat. Sol. C 94, 2181–2186 (2010). https://doi.org/10.1016/j.solmat.2010.07.009

Y.C. Yoon, K.S. Park, S.D. Kim, Effects of low preheating temperature for ZnO seed layer deposited by sol–gel spin coating on the structural properties of hydrothermal ZnO nanorods. Thin Solid Films 597, 125–130 (2015). https://doi.org/10.1016/j.tsf.2015.11.040

S. Yilmaz, The geometric resistivity correction factor for several geometrical samples. J. Semicond. 36(082001), 2015 (2015). https://doi.org/10.1088/1674-4926/36/8/082001

H. Çolak, O. Turkoglu, Structural and electrical properties of V-doped ZnO prepared by the solid state reaction. J. Mater. Sci- Mater. El 23, 1750–1758 (2012). https://doi.org/10.1007/s10854-012-0657-1

RC Weast. Handbook of Chemistry and Physics, 56nd ed. (Newyork, Crc Pres., pp. F-198–199, 1975–1976.

S. Goel, N. Sinha, H. Yadav, S. Godara, A.J. Joseph, B. Kumar, Ferroelectric Gd-doped ZnO nanostructures: enhanced dielectric, ferroelectric and piezoelectric properties. Mater. Chem. Phys. 202, 56–64 (2017). https://doi.org/10.1016/j.matchemphys.2017.08.067

H. Çolak, O. Türkoğlu, Effect of doping and high-temperature annealing on the structural and electrical properties of Zn1−xNixO (0 ≤ x ≤ 0.15) powders. J. Mater. Sci. Tech. 27, 944–995 (2012). https://doi.org/10.1007/s10854-012-0657-1

H. Çolak, E. Karaköse, Electrical and optical properties of well aligned Ho3+-doped ZnO nanorods as an alternative transparent conducting oxide. J. Min. Met. Mat. S 73, 395–403 (2021). https://doi.org/10.1007/s11837-020-04483-z

P. Scherrer, Bestimmung der Grösse und der inneren Struktur von Kolloidteilchen mittels Röntgenstrahlen. Nachr Ges Wiss Göttingen 26, 98–100 (1918)

A. Jimenez-Gonzalez, S. Suarez-Parra, Effect of heat treatment on the properties of ZnO thin films prepared by successive ion layer adsorption and reaction (SILAR). J. Cryst. Growth 167, 649–655 (1996). https://doi.org/10.1016/0022-0248(96)00308-9

A. Janotti, C.G. Van de Walle, Fundamentals of zinc oxide as a semiconductor. Rep. Prog. Phys. 72, 126501 (2009). https://doi.org/10.1088/0034-4885/72/12/126501

M. Behrens, G. Lolli, N. Muratova, I. Kasatkin, M. Hävecker, R.N. d’Alnoncourt, O. Storcheva, K. Köhler, M. Muhler, R. Schlögl, The effect of Al-doping on ZnO nanoparticles applied as catalyst support. Phys. Chem. Chem. Phys. 15, 1374–1381 (2013). https://doi.org/10.1039/C2CP41680H

M.M. Rahman, M.K.R. Khan, M.R. Islam, M.A. Halim, M. Shahjahan, M.A. Hakim, D.K. Saha, J.U. Khan, Effect of Al doping on structural, electrical, optical and photoluminescence properties of nano-structural ZnO thin films. J. Mater. Sci. Tech. 28, 329–335 (2012). https://doi.org/10.1016/S1005-0302(12)60064-4

R. Bhardwaj, A. Bharti, J.P. Singh, K.H. Chae, N. Goyal, Influence of Cu doping on the local electronic and magnetic properties of ZnO nanostructures. Nanoscale Adv. 2, 4450–4463 (2020). https://doi.org/10.1039/D0NA00499E

H. Çolak, Influence of Tm2O3 doping on structural and electrical properties of ZnO. J. Mater. Sci- Mater. El 26, 784–790 (2015). https://doi.org/10.1007/s10854-014-2464-3

A.V. Patil, C.G. Dighavkar, S.K. Sonawane, S.J. Patil, R.Y. Borse, Effect of firing temperature on electrical and structural characteristics of screen printed ZnO thick films. J. Optoelectron. Biomed. Mater. 1, 226–233 (2009)

E.M. Mkawi, K. Ibrahim, M.K.M. Ali, M.A. Farrukh, A.S. Mohamed, The effect of dopant concentration on properties of transparent conducting Al-doped ZnO thin films for efficient Cu2ZnSnS4 thin-film solar cells prepared by electrodeposition method. Appl. Nanosci. 5, 993–1001 (2015). https://doi.org/10.1007/s13204-015-0400-3

J. Tauc, Optical properties and electronic structure of amorphous Ge and Si. Mater. Res. Bull. 3, 37–46 (1968). https://doi.org/10.1016/0025-5408(68)90023-8

F.J. Serrao, N.N. Bappalige, K.M. Sandeep, S. Raghavendr, Dominance of c-axis orientation on the carrier transport properties of Sn doped ZnO thin films. Thin Solid Films 722, 138579 (2021). https://doi.org/10.1016/j.tsf.2021.138579

J.T. Chen, J. Wang, F. Zhang, G.A. Zhang, Z.G. Wu, P.X. Yan, The effect of La doping concentration on the properties of zinc oxide films prepared by the sol–gel method. J. Cryst. Growth 310, 2627–2632 (2008). https://doi.org/10.1016/j.jcrysgro.2008.01.011

Author information

Authors and Affiliations

Contributions

HÇ: ınvestigation, writing—original manuscript, supervision. HİM: ınvestigation.

Corresponding author

Ethics declarations

Conflict of interest

Authors declare that there are no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Çolak, H., Mercan, H.İ. Influence of thallium doping on structural, electrical, and optical properties of ZnO nanorods for TCO applications. J Mater Sci: Mater Electron 33, 14816–14828 (2022). https://doi.org/10.1007/s10854-022-08401-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-022-08401-8