Abstract

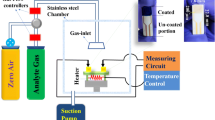

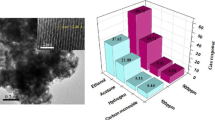

Bio-fuel, a blend of ethanol (~ 10 to 85%) and gasoline with various compositions, is one of the promising next generation energy sources in automobile industries, especially in flex-fuel vehicles. Here, the detection of ethanol content is essential for adjusting different fuel combustion parameters. But till date no dedicated sensor is available in the market for this purpose. With this perspective, in the present work, we have developed a selective ethanol sensor based on La3+ impregnated TiO2, which would be capable to detect and differentiate different high concentration of ethanol in gasoline quite precisely. We have used a facile sol–gel procedure to synthesize the pristine and La-impregnated (~ 2 to 6 at.%) titania nanopowders. The phase transformation, structural, and morphological analyses were carried out using thermogravimetric analysis (TGA), X-ray diffraction (XRD), transmission electron microscope (TEM), energy dispersive X-ray (EDX), UV–Visible and photoluminescence (PL) measurements. Taguchi type sensors were fabricated from the as-prepared powders and their ethanol sensing performances were studied. ~ 4 at.% of La concentration was found to be most efficient to stabilize the sensing favorable anatase phase of TiO2, as well as gave the best sensing response, ~ 82% in 10% ethanol at operating temperature of ~ 350 °C. This sensing response increased to 96% for pure ethanol. The selectivity of the sensor toward the ethanol with respect to other gases in bio-fuel was quite high. A model bio-fuel composition (E10) was also prepared and performance was evaluated.

Similar content being viewed by others

Data availability statement

As the reported work is the outcome of a funded project of CSIR-India (MLP0308). The detailed data of the work is not available.

References

C. Wang, Z.G. Wang, R. Xi, L. Zhang, S.H. Zhang, L.J. Wang, In situ synthesis of flower-like ZnO on GaN using electrodeposition and its application as ethanol gas sensor at room temperature. Sens. Actuators B 292, 270–276 (2019). https://doi.org/10.1016/j.snb.2019.04.140

R. Luque, C.S.K. Lin, K. Wilson, J. Clark. Handbook of Biofuels Production. Processes and Technologies. Second edition 2016.

S.T. Coelho, J. Goldemberg. Alternative Transportation Fuels: Contemporary Case Studies. Encyclopedia of Energy, 2004

R.J.Pearson, J.W.G.Turner. 3 - Using alternative and renewable liquid fuels to improve the environmental performance of internal combustion engines: key challenges and blending technologies. doi: https://doi.org/10.1533/9780857097422.1.52

L.M. Middelburg, G. de Graaf, A. Bossche, J. Bastemeijer, M. Ghaderi, F.S. Wolffenbuttel, J. Visser, R. Soltis, R.F. Wolffenbuttel, Multi-domain spectroscopy for composition measurement of water-containing bio-ethanol fuel. Fuel Process. Technol. 167, 127–135 (2017). https://doi.org/10.1016/j.fuproc.2017.06.007

H. Richard, A. PIANU, Infrared Optical Sensor Incorporating a Transmission Measuring Cell, US Patent App. 14/168,789(2014). https://www.google.ch/patents/US20140211197

K. Ahn, A.G. Stefanopoulou. Estimation of ethanol content in flex-fuel vehicles using an exhaust gas oxygen sensor: model , tuning and sensitivity. ASME Dynamic Systems and Control Conference. https://doi.org/10.1115/DSCC2008-2232.

K. Ahn, A. Stefanopoulou. Ethanol content estimation in flex fuel direct injection engines using in-cylinder pressure measurements. https://doi.org/10.4271/2009-01-0657

A. Conklin, M.J. Goldcamp, J. Barrett, Determination of ethanol in gasoline by FT-IR spectroscopy. J. Chem. Educ. 6, 889–891 (2014). https://doi.org/10.1021/ed400824g

V. Semwal, A.M. Shrivastav, R. Verma, B.D. Gupta, Surface plasmon resonance based fiber optic ethanol sensor using layers of silver/silicon/hydrogel entrapped with ADH/NAD. Sens. Actuators B Chem. 30, 485–492 (2016). https://doi.org/10.1016/j.snb.2016.02.084

G. Jeevitha, R. Abhinayaa, D. Mangalaraj, N. Ponpandian, P. Meena, V. Mounasamy, S. Madanagurusamy, Porous reduced graphene oxide (rGO)/WO3 nanocomposites for the enhanced detection of NH3 at room temperature. Nanoscale Adv. 1, 1799 (2019). https://doi.org/10.1039/c9na00048h

S. Sen, S. Kundu, Reduced graphene oxide (rGO) decorated ZnO-SnO2: A ternary nanocomposite towards improved low concentration VOC sensing performance. J. Alloys Compd. 881, 160406 (2021). https://doi.org/10.1016/j.jallcom.2021.160406

S. Sen, A. Nilabh, S. Kundu, Room temperature acetone sensing performance of Pt/Sb2O3 impregnated Fe2O3 thin film: non invasive diabetes detection. Microchem. J. 165, 106111 (2021). https://doi.org/10.1016/j.microc.2021.106111

T.J. Giffney, Y.H. Ng, K.C. Aw, A surface acoustic wave ethanol sensor with zinc oxide nanorods. Smart Mater. Res. (2012). https://doi.org/10.1155/2012/210748

A. Mirzaei, S.G. Leonardi, G. Neri, Detection of hazardous volatile organic compounds (VOCs) by metal oxide nanostructures-based gas sensors: a review. Ceramics 42, 15119–15141 (2016). https://doi.org/10.1016/j.ceramint.2016.06.145

L. Wang, Y. Kang, X. Liu, S. Zhang, W. Huang, S. Wang, ZnO nanorod gas sensor for ethanol detection. Sens. Actuators B 162, 237–243 (2012). https://doi.org/10.1016/j.snb.2011.12.073

Q. Wan, Q.H. Li, Y.J. Chen, T.H. Wang, X.L. He, J.P. Li, C.L. Lin, Fabrication and ethanol sensing characteristics of ZnO nanowiregas sensors. Appl. Phys. Lett. 84, 3654 (2004). https://doi.org/10.1063/1.1738932

S. Choopun, N. Hongsith, P. Mangkorntong, N. Mangkorntong, Zinc oxide nanobelts by RF sputtering for ethanol sensor. Physica E 39, 53–56 (2007). https://doi.org/10.1016/j.physe.2006.12.053

T. Tharsika, M. Thanihaichelvan, A.S.M.A. Haseeb, S.A. Akbar, Highly Sensitive and Selective Ethanol Sensor Based on ZnO Nanorod on SnO2 Thin Film Fabricated by Spray Pyrolysis. Front. Mater. 6, 122 (2019). https://doi.org/10.3389/fmats.2019.00122

Z. Lou, J. Deng, L. Wang, L. Wang, T. Fei, T. Zhang, Toluene and ethanol sensing performances of pristine and PdO-decorated flower-like ZnO structures. Sens. Actuators B 176, 323–329 (2013). https://doi.org/10.1016/j.snb.2012.09.027

L.K. Bagal, J.Y. Patil, M.V. Vaishampayan, I.S. Mulla, S.S. Suryavanshi, Effect of Pd and Ce on the enhancement of ethanol vapor response of SnO2 thick films. Sens. Actuators B 207, 383–390 (2014). https://doi.org/10.1016/j.snb.2014.10.021

K. Kawamura, M. Vestergaard, M. Ishiyama, N. Nagatani, T. Hashiba, E. Tamiya, Development of a novel hand-held toluene gas sensor: possible use in the prevention and control of sick building syndrome. Measurement 39, 490–496 (2006). https://doi.org/10.1016/j.measurement.2005.12.014

N.V. Hieu, N.A.P. Duc, T. Trung, M.A. Tuan, N.D. Chien, Gas-sensing properties of tin oxide doped with metal oxides and carbon nanotubes: a competitive sensor for ethanol and liquid petroleum gas. Sens. Actuators B 144, 450–456 (2009). https://doi.org/10.1016/j.snb.2009.03.043

R.G. Motsoeneng, I. Kortidis, S. Sinha, R. David, E. Motaung, Designing SnO2 nanostructure-based sensors with tailored selectivity toward propanol and ethanol vapors. ACS Omega 4, 13696–13709 (2019). https://doi.org/10.1021/acsomega.9b01079

A. K. Vishwakarmaa, A. K. Sharma and L. Yadav. Theoretical modeling of Pd-SnO2 based ethanol gas sensor J. Phys.: Conf. Ser. 1921,012118(2021). doi: https://doi.org/10.1088/1742-6596/1921/1/012118.

K. Ryu, D. Zhang, C. Zhou, High-performance metal oxide nanowire chemical sensors with integrated micromachined hotplates. Appl. Phys. Lett. 92, 093111 (2008). https://doi.org/10.1063/1.2841665

W. Zheng, X. Lu, W. Wang, Z. Li, H. Zhang, Y. Wang, Z. Wang, C. Wang, A highly sensitive and fast-responding sensor based on electrospun In2O3 nanofibers. Sens. Actuators B 42, 61–65 (2009). https://doi.org/10.1016/j.snb.2009.07.031

C. Shen, N. Xu, R. Guan, L. Yue, W. Zhang, Highly sensitive ethanol gas sensor based on In2O3 spheres. Ionics 27, 3647–3653 (2021). https://doi.org/10.1007/s11581-021-04057-2

S. Park, S. Kim, G.J. Sun, C. Lee, Synthesis, structure, and ethanol gas sensing properties of In2O3 nanorods decorated with Bi2O3 nanoparticles. ACS Appl. Mater. Interfaces 7, 8138–8146 (2015). https://doi.org/10.1021/acsami.5b00972

D.E. Gbenga, H.I. Hamed, A.A. Lateef, A.E. Opeyemi, Alcohol detection of drunk drivers with automatic car engine locking system. Nova J. Eng. Appl. Sci. 6(1), 1–15 (2017). https://doi.org/10.20286/nova-jeas-060104

S. Singh, H. Kaur, V.N. Singh, K. Jain, T.D. Senguttuvan, Highly sensitive and pulse-like response toward ethanol of Nb doped TiO2 nanorods based gas sensors. Sens. Actuators B 171–172, 899–906 (2012). https://doi.org/10.1016/j.snb.2012.06.002

J. Jiu, S. Isoda, F. Wang, M. Adachi, Dye-sensitized solar cells based on a single-crystalline TiO2 nanorod film. J. Phys. Chem. B 110, 2087–2092 (2006). https://doi.org/10.1021/jp055824n

G.B. Shan, G.P. Demopoulos, The synthesis of aqueous-dispersible anatase TiO2 nanoplatelets. Nanotechnology 21, 025604 (2010). https://doi.org/10.1088/0957-4484/21/2/025604

X.L. Li, Q. Peng, J.X. Yi, X. Wang, Y. Li, Near monodisperse TiO2 nanoparticles and nanorods. Chem. Eur. J. 12, 2383–2391 (2006). https://doi.org/10.1002/chem.200500893

S.T. Navale, Z.B. Yang, C. Liu, P.J. Cao, V.B. Patil, N.S. Ramgir, R.S. Manee, F.J. Stadler, Enhanced acetone sensing properties of titanium dioxide nanoparticles with a sub-ppm detection limit. Sens. Actuators B 255, 1701–1710 (2018). https://doi.org/10.1016/j.snb.2017.08.186

P.V. Viet, B.T. Phan, L.V. Hieu, C.M. Thi, The effect of acid treatment and reactive temperature on the formation of TiO2 nanotubes. J. Nanosci. Nanotechnol. 15, 5202–5206 (2015). https://doi.org/10.1166/jnn.2015.10025

B. Bhowmik, P. Bhattacharyya. Efficient gas sensor devices based on surface engineered oxygen vacancy controlled TiO2 nanosheets. IEEE Tran. Electron. Dev. (2017). https://doi.org/10.1109/TED.2017.2686425

S. Prabakar, C.W. Bumby, R.D. Tilley, Liquid-Phase Synthesis of Flower-like and Flake-like Titanium Disulfide Nanostructures. Chem. Mater. 21, 1725–1730 (2009). https://doi.org/10.1021/cm900110h

T. Luttrell, S. Halpegamage, J. Tao, A. Kramer, E. Sutter, M. Batzill, Why is anatase a better photocatalystthan rutile?—Model studies on epitaxial TiO2 films. Sci. Rep. 4, 4043 (2014). https://doi.org/10.1038/srep04043

S. Nasirian, H.M. Moghaddam, Hydrogen gas sensing based onpolyaniline/anatasetitania nanocomposite. Int. J. Hydrogen. Energy 39, 630–642 (2014). https://doi.org/10.1016/j.ijhydene.2013.09.152

X. Chen, S.S. Mao, Titanium dioxide nanomaterials: synthesis, properties, modifications, and applications. Chem. Rev. 107, 2891–2959 (2007). https://doi.org/10.1021/cr0500535

O. Carp, C.L.H. Reller, Photoinduced reactivity of titanium dioxide. Prog. Solid State Chem. 32, 33–177 (2004). https://doi.org/10.1016/j.progsolidstchem.2004.08.001

M.A.H. Khan, B. Thomson, R. Debnath, A. Rani, A.M. Mulpuri, V. Rao, Reliable anatase-titania nanoclusters functionalized GaN sensor devices for UV assisted NO2 gas-sensing in ppb level. Nanotechnology 31, 155–504 (2020). https://doi.org/10.1088/1361-6528/ab6685

C. Byrne, R. Fagan, S. Hinder, D.E. McCormack, S.C. Pillai, New approach of modifying the anatase to rutile transitiontemperature in TiO2 photocatalysts. RSC Adv. 6, 95232–95238 (2016). https://doi.org/10.1039/C6RA19759K

Q. Zhang, C. Li, High temperature stable anatase phase titanium dioxide films synthesized by mist chemicalvapor deposition. Nanomaterials 10, 911 (2020). https://doi.org/10.3390/nano10050911

S. Kundu, P.K. Warran, S.M. Mursalin, M. Narjinary, Synergistic effect of Pd and Sb incorporation on ethanol vapourdetection of La doped tin oxide sensor. J. Mater. Sci.: Mater. Electron. 26, 9865–9872 (2015). https://doi.org/10.1007/s10854-015-3662-3

M.W. Lianfeng, Z. Changyue, Z. Guosheng, G. Xuewen, J. Baohua, L.Y. Yao, Lanthanum oxide @ antimony-doped tin oxide with high gas sensitivity and selectivity towards ethanol vapor. Sens. Actuators B 224, 478–484 (2016). https://doi.org/10.1016/j.snb.2015.10.083

D. Han, J. Yang, F. Gu, Z. Wang, Effects of rare earth elements doping on ethanol gas sensing performance of three-dimensionally ordered macroporous In2O3. RSC Adv. 6, 45085–45092 (2016). https://doi.org/10.1039/C6RA06816B

A. Benali, M. Bejar, E. Dhahri, M.P.F. Graça, M.A. Valente, A. Radwan, High ethanol gas sensing property and modulation of magneticand AC-conduction mechanism in 5% Mg-doped La0.8 Ca0.1 Pb0.1 FeO3 compound. J. Mater. Sci.: Mater. Electron. 30, 12389–12398 (2019). https://doi.org/10.1007/s10854-019-01597-2

S. Kundu, A. Choudhury, S.M. Mursalin, M. Narjinary, Raju Manna. Synthesis, characterization and low concentration ethanol sensing performance of sol–gel derived La(III) doped tin oxide. J Mater Sci: Mater Electron. 26,6252–6260(2015). doi: https://doi.org/10.1007/s10854-015-3211-0.

M.M. Mahlambi, A.K. Mishra, S.B. Mishra, R.W. Krause, B.B. Mamba, A.M. Raichur, Comparison of rhodamine B degradation under UV irradiation by two phases of titania nano-photocatalyst. J. Therm. Anal. Calorim. 110, 847–855 (2012). https://doi.org/10.1007/s10973-011-1852-7

C. Byrne, R. Fagan, S. Hinder, D.E. McCormack, S.C. Pillai, New approach of modifying the anatase to rutile transition temperature in TiO2 photocatalysts. RSC Adv. 6, 95232–95238 (2016). https://doi.org/10.1039/C6RA19759K

A. Matthews, The crystallization of anatase and rutile from amorphous titanium dioxide under hydrothermal. Am. Miner. 61, 419424 (1976)

D.A.H. Hanaor, C.C. Sorrell, Review of the anatase to rutile phase transformation. J Mater Sci. 46, 855–874 (2011). https://doi.org/10.1007/s10853-010-5113-0

T.B. Ghosh, S. Dhaba, A.K. Datta, On crystallite size dependence of phase stability of nanocrystalline TiO2. J. Appl. Phys. 94, 4577 (2003). https://doi.org/10.1063/1.1604966

C.P. Sibu, S. Rajesh Kumar, P. Mukundan, K.G.K. Warrier, Structural modifications and associated properties of lanthanum oxide doped sol-gel nanosized titanium oxide. Chem. Mater. 14, 2876–2881 (2002). https://doi.org/10.1021/cm010966p

L. Wang, Y. Zhang, H. Guo, J. Li, E.A. Stach, X. Tong, E.S. Takeuchi, K.J. Takeuchi, P. Liu, A.C. Marschilok, S.S. Wong, Structural and electrochemical characteristics of Ca-doped “Flowerlike” Li4Ti5O12 motifs as high-rate anode materials for lithium-ion batteries. Chem. Mater. 30, 671–684 (2018). https://doi.org/10.1021/acs.chemmater.7b03847

R. Nawaz, C.F. Kait, H.Y. Chia, M.H. Isa, L.W. Huei, Glycerol-mediated facile synthesis of colored titania nanoparticles for visible light photodegradation of phenolic compounds. Nanomaterials 9, 1586 (2019). https://doi.org/10.3390/nano9111586

B.P. Payne, M.C. Biesinger, N.S. McIntyre, Use of oxygen/nickel ratios in the XPS characterisation of oxide phases on nickel metal and nickel alloy surfaces. J. Electron Spectrosc. Relat. Phenom. 185, 159–166 (2012). https://doi.org/10.1016/j.elspec.2012.06.008

Y. Lee, C. Hwon Lee, T. Nam, S. Lee, I.K. Oh, J.Y. Yang, D.W. Choi, C. Yoo, H.J. Kim, W.H. Kim, H. Kim, Hydrogen barrier performance of sputtered La2O3 films for InGaZnO thin-film transistor. J Mater Sci. 54, 11145–11156 (2019). https://doi.org/10.1007/s10853-019-03685-4

F. Li, Yu. Kai, L.-L. Lou, Su. Zhiqian, S. Liu, Theoretical and experimental study of La/Ni co-doped SrTiO3 photocatalyst. Mater. Sci. Eng., B 172, 136–141 (2010). https://doi.org/10.1016/j.mseb.2010.04.036

A. Jia, Z. Su, L.L. Lou, S. Liu, Synthesis and characterization of highly-active nickel and lanthanum co-doped SrTiO3. Solid State Sci. 12, 1140–1145 (2010). https://doi.org/10.1016/j.solidstatesciences.2010.04.005

S. Mathew, A.K. Prasad, T. Benoy, P.P. Rakesh, M. Hari, T.M. Libish, P. Radhakrishnan, V.P.N. Nampoori, C.P.G. Vallabhan, UV-visible photoluminescence of TiO2 nanoparticles preparedby hydrothermal method. J. Fluoresc. 22, 1563–1569 (2012). https://doi.org/10.1007/s10895-012-1096-3

A.K. Tripathi, M.K. Singh, M.C. Mathpal, S.K. Mishra, A. Agarwal, Study of structural transformation in TiO2 nanoparticles and its optical properties. J. Alloys Compds. 549, 114–120 (2013). https://doi.org/10.1016/j.jallcom.2012.09.012

X. Li, R. Ramasamy, P.K. Dutta, Study of the resistance behavior of anatase and rutile thick films towards carbon monoxide and oxygen at high temperatures and possibilities for sensing applications. Sens. Actuators B 143, 308–315 (2009). https://doi.org/10.1016/j.snb.2009.09.021

D. Schwarzenbach, The structure of a chelated dinuclear peroxytitanium(1V). Inorg. Chem. 9, 11 (1970). https://doi.org/10.1021/ic50093a002

S. Bakardjieva, J. Mares, R. Fajgar, V.Y. Zenou, M. Maleckova, E. Chatzisymeon, H. Bibovaf, J. Jirkovskyf, The relationship between microstructure and photocatalytic behavior in lanthanum-modified 2D TiO2 nanosheets upon annealing of a freeze-cast precursor. RSC Adv. 9, 22988 (2019). https://doi.org/10.1039/c9ra03940f

Sovandeb Sen, Sourav Maity, Susmita Kundu. Fabrication of Fe doped reduced graphene oxide (rGO) decorated WO3 based low temperature ppm level acetone sensor: Unveiling sensing mechanism by impedance spectroscopy. 361, 131-706 (2022). doi: https://doi.org/10.1016/j.snb.2022.131706

S. Kundu, R. Sudarshan, M. Narjinary, Pd impregnated gallia: Tin oxide nanocomposite—an excellent high temperature carbon monoxide sensor. Sens. Actuators B 254, 437–447 (2018). https://doi.org/10.1016/j.snb.2017.07.094

Acknowledgments

The authors are expressing their gratitude to The Director, CSIR-CGCRI and Head Functional Materials and Devices Division for the permission to publish the paper. Materials Characterization Division of CSIR-CGCRI is also acknowledged for extending their facilities. The authors are also thankful to Md. Jalaluddin Mondal and Raju Manna for their help in sensor module preparation. The financial help from project MLP0308 also acknowledged.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation, data collection and analysis were performed by SB and SS. The first draft of the manuscript was written by SB and SK revised the manuscript for important intellectual content. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Bhattacharjee, S., Sen, S. & Kundu, S. Development of La-impregnated TiO2 based ethanol sensors for next generation automobile application. J Mater Sci: Mater Electron 33, 15296–15312 (2022). https://doi.org/10.1007/s10854-022-08394-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-022-08394-4