Abstract

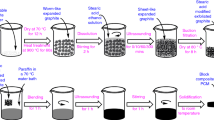

To achieve shape-stabilized phase change composites with high phase change material (PCM) load and high thermal conductivity, a series of mesoporous silica–graphene composites containing varying amounts of graphene were produced and used as supports, and paraffin was utilized as PCM. The characteristics of mesoporous silica–graphene supports and phase change material composites were analyzed using N2 adsorption and desorption, X-ray diffraction, field emission scanning electron microscopy, Fourier transform infrared spectrometer, differential scanning calorimetry, and thermogravimetry analysis. The pore size of the resultant mesoporous silica–graphene supports ranged from 4.63 to 5.92 nm, with a surface area of 564–664 m2g−1. The results revealed that the composite containing 100 mg initial graphene oxide (PA/MS-100GO) had a maximum melting and solidification phase change enthalpy of 141.45 and 149.70 J g−1, as well as a maximum paraffin loading capacity of 85 wt%. The thermal conductivity of the PA/MS-100GO composite was 0.84 W m−1 K−1, which is 342% higher than pure paraffin. Within operating temperatures of less than 250 °C, all composite PCMs produced in this study demonstrated high thermal stability and chemical compatibility. Consequently, the produced shape-stabilized composite PCMs with good thermal characteristics, thermal conductivity, and chemical stability are desirable for heat energy storage applications.

Similar content being viewed by others

Data availability

All data generated or analyzed during this study are included in this published article.

References

A. Sharma, V.V. Tyagi, C.R. Chen, D. Buddhi, Renew. Sustain. Energy Rev. (2009). https://doi.org/10.1016/j.rser.2007.10.005

G. Fang, F. Tang, L. Cao, Renew. Sustain. Energy Rev. (2014). https://doi.org/10.1016/j.rser.2014.07.179

Y. Li, H. Yan, Q. Wang, H. Wang, Y. Huang, J. Therm. Anal. Calorim. (2017). https://doi.org/10.1007/s10973-016-6068-4

Y. Tang, Y. Lin, Y. Jia, G. Fang, Energy Build. (2017). https://doi.org/10.1016/j.enbuild.2017.08.005

M. Li, Q. Guo, S. Nutt, J. Sol. Energy (2017). https://doi.org/10.1016/j.solener.2017.02.003

B. Li, S. Nie, Y. Hao, T. Liu, J. Zhu, S. Yan, Energy Convers. Manag. (2015). https://doi.org/10.1016/j.enconman.2015.04.002

Y. Zhou, X. Liu, D. Sheng, C. Lin, F. Ji, L. Dong, S. Xu, H. Wu, Y. Yang, Chem. Eng. J. (2018). https://doi.org/10.1016/j.cej.2018.01.021

J. Yang, G.-Q. Qi, R.-Y. Bao, K. Yi, M. Li, L. Peng, Z. Cai, M.-B. Yang, D. Wei, W. Yang, Energy Stor. Mater. (2018). https://doi.org/10.1016/j.ensm.2017.12.028

Y. Deng, J. Li, Y. Deng, H. Nian, H. Jiang, ACS Sustain. Chem. Eng. (2018). https://doi.org/10.1021/acssuschemeng.8b00631

X. Zhang, Q. Ding, H. Luo, B. Hui, Z. Chang, J. Zhang, Infrared Phys. Technol. (2017). https://doi.org/10.1016/j.infrared.2017.09.016

Y. Chen, X. Zhang, B. Wang, M. Lv, Y. Zhu, RSC Adv. (2017). https://doi.org/10.1039/C7RA00964J

T. Nomura, C. Zhu, N. Sheng, K. Tabuchi, A. Sagara, T. Akiyama, Sol. Energy Mater. Sol. Cells (2015). https://doi.org/10.1016/j.solmat.2015.07.028

J. Puig, I.E. Dell-Erba, W.F. Schroeder, C.E. Hoppe, R.J.J. Williams, ACS Appl. Mater. Interfaces (2017). https://doi.org/10.1021/acsami.7b00086

Q. Lian, K. Li, A.A.S. Sayyed, J. Cheng, J. Zhang, J. Mater. Chem. A (2017). https://doi.org/10.1039/C7TA02816D

J. Wang, M. Yang, Y. Lu, Z. Jin, Nano Energy (2016). https://doi.org/10.1016/j.nanoen.2015.11.001

T. Kadoono, M. Ogura, Phys. Chem. Chem. Phys. (2014). https://doi.org/10.1039/C3CP55429E

R.-A. Mitran, D. Berger, C. Munteanu, J. Phys. Chem. C (2015). https://doi.org/10.1021/acs.jpcc.5b02608

Y. Yu, J. Xu, G. Wang, R. Zhang, X. Peng, J. Mater. Sci. (2020). https://doi.org/10.1007/s10853-019-04107-1

J. Choi, H. Fujita, M. Ogura, A. Sakoda, Adsorption (2018). https://doi.org/10.1007/s10450-018-9946-1

J. Li, X. Hu, C. Zhang, W. Luo, X. Jiang, Renew. Energy (2021). https://doi.org/10.1016/j.renene.2021.06.021

M. Li, Z. Wu, J. Tan, Appl. Energy (2012). https://doi.org/10.1016/j.apenergy.2011.11.018

X. Han, T. Zhao, X. Gao, H. Li, Coll. Surf. A Physicochem. Eng. Asp. (2018). https://doi.org/10.1016/j.colsurfa.2018.01.043

X. Zhang, C. Zhu, G. Fang, Mater. Chem. Phys. (2020). https://doi.org/10.1016/j.matchemphys.2019.122178

Y. Zhang, K. Sun, Y. Kou, S. Wang, Q. Shi, Sol. Energy (2020). https://doi.org/10.1016/j.solener.2020.06.048

Y. Chen, X. Li, J. Gao, M. Yang, Y. Liu, Y. Liu, X. Tang, J. Mater. Sci. (2021). https://doi.org/10.1007/s10853-020-05638-8

J. Chen, B. Yao, C. Li, G. Shi, Carbon (2013). https://doi.org/10.1016/j.carbon.2013.07.055

R. Luo, S. Wang, T. Wang, C. Zhu, T. Nomura, T. Akiyama, Energy Build. (2015). https://doi.org/10.1016/j.enbuild.2015.09.043

T. Qian, J. Li, H. Ma, J. Yang, Sol. Energy Mater. Sol. Cells (2015). https://doi.org/10.1016/j.solmat.2014.08.017

A. Hussain, I.H. Abidi, C.Y. Tso, K.C. Chan, Z. Luo, C.Y.H. Chao, Int. J. Therm. Sci. (2018). https://doi.org/10.1016/j.ijthermalsci.2017.09.019

Funding

The authors declare that no funds, grants, or other support were received during the preparation of this manuscript. The authors have no relevant financial or non-financial interests to disclose.

Author information

Authors and Affiliations

Contributions

MF contributed to methodology, formal analysis, data curation, investigation, and writing the original draft. FK contributed to supervision, writing review, and editing. KR contributed to writing review and editing.

Corresponding authors

Ethics declarations

Conflict of interest

All authors certify that they have no affiliations with or involvement in any organization or entity with any financial or non-financial interest in the subject matter or materials discussed in this manuscript.

Ethical approval

This material is the authors’ original work, which has not been previously published elsewhere. All authors have been personally and actively involved in substantial work leading to the paper and will take public responsibility for its content.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Falahatian, M., Karimzadeh, F. & Raeissi, K. Preparation of paraffin/silica–graphene shape-stabilized composite phase change materials for thermal energy storage. J Mater Sci: Mater Electron 33, 12846–12856 (2022). https://doi.org/10.1007/s10854-022-08229-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-022-08229-2