Abstract

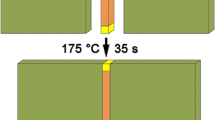

Sn-58Bi solder has attracted much attention due to its low melting temperature and low cost in recent years. However, Sn-58Bi solder might occur locally melting due to the high local temperature by Joule heating and consequently raises serious reliability problems. In this study, the growth mechanisms of interfacial intermetallic compounds (IMCs) and Bi-rich layer of the ball grid array structure Cu/Sn-58Bi/Cu joints during both solid–solid (S–S) electromigration in solid solder and liquid–solid (L–S) electromigration in molten solder were investigated comprehensively. Results show that during S–S electromigration at 70 οC, current stressing induces a reverse polarity effect on the growth of interfacial IMCs, i.e., the interfacial IMCs on the cathode side is thicker than that on the anode side. Besides, Bi atoms accumulate to form a Bi-rich layer on the anode side. During S–S electromigration at 135 οC, current stressing causes a reverse polarity effect on the growth of interfacial IMCs, and Bi atoms on the anode side reversely diffuse into the solder, resulting in the disappearance of Bi-rich layer. During L–S electromigration at both 150 οC and 170 οC, current stressing induces a polarity effect on the growth of interfacial IMCs, i.e., the interfacial IMCs on the anode side is thicker than that on the cathode side. Furthermore, there is no Bi-rich layer on the anode side. The transition in growth mechanism of interfacial IMCs from the reverse polarity effect to the polarity effect is determined by the combined effect of the electronic wind force flux (Jem) and the chemical potential gradient flux (Jchem).

Similar content being viewed by others

Data availability

The data and materials that support the findings of this study are available from the corresponding author upon reasonable request. The data are not publicly available as the data also forms part of an ongoing study.

References

J.A. Depiver, S. Mallik, E.H. Amalu, Eng. Fail. Anal. 125, 105447 (2021)

K.M. Chu, C.S. Lee, S.H. Park, Y.C. Sohn, Microelectron. Reliab. 75, 53 (2017)

F.J. Wang, L.T. Liu, M.F. Wu, D.Y. Li, J. Mater. Sci. Mater. Electron. 29, 8895 (2018)

Y.L. Chen, J.Y. Jia, H.Z. Fu, Z. Zeng, Int. J. Fatigue 87, 216 (2016)

Y. Ma, X.Z. Li, L.Z. Yang, W. Zhou, M.X. Wang, W.B. Zhu, P. Wu, Mater. Sci. Eng. A 696, 437 (2017)

S.B. Liang, C.B. Ke, J.Q. Huang, M.B. Zhou, X.P. Zhang, Microelectron. Reliab. 92, 1 (2019)

N. Jiang, L. Zhang, L.L. Gao, W.M. Long, S.J. Zhong, L. Zhang, J. Mater. Sci. Mater. Electron. 32, 16970 (2021)

K.D. Min, K.H. Jung, C.J. Lee, B.U. Hwang, S.B. Jung, J. Alloys Compd. 857, 157595 (2021)

Y.X. Liu, Y.C. Chu, K.N. Tu, Acta Mater. 117, 146 (2016)

H.B. Qin, T.H. Liu, W.Y. Li, W. Yue, D.G. Yang, Microelectron. Reliab. 115, 113995 (2020)

M.L. Huang, Q. Zhou, N. Zhao, X.Y. Liu, Z.J. Zhang, J. Mater. Sci. 49, 1755 (2014)

F.J. Wang, H. Chen, D.Y. Li, Z.J. Zhang, X.J. Wang, Electron. Mater. Lett. 15, 36 (2019)

Z.J. Zhang, M.L. Huang, Acta. Metall. Sin. 56, 1386 (2020)

X. Gu, K.C. Yung, Y.C. Chan, J. Mater. Sci. Mater. Electron. 21, 1090 (2010)

D.L. Ma, P. Wu, Mater. Sci. Eng. A 651, 499 (2016)

J.Q. Huang, M.B. Zhou, X.P. Zhang, J. Electron. Mater. 46, 1504 (2017)

T. Siewert, S. Liu, D.R. Smith, J.C. Madeni, in Properties of Lead-Free Solders (2002)

Z. Wang, Q.K. Zhang, Y.X. Chen, Z.L. Song, J. Mater. Sci. Mater. Electron. 30, 18524 (2019)

S.M. Lee, J.W. Yoon, S.B. Jung, J. Mater. Sci. Mater. Electron. 27, 1105 (2015)

F. Guo, Q. Liu, L.M. Ma, Y. Zuo, J. Mater. Res. 31, 1793 (2016)

S.B. Liang, C.B. Ke, C. Wei, J.Q. Huang, M.B. Zhou, X.P. Zhang, J. Mater. Res. 34, 2775 (2019)

J.R. Huang, C.M. Tsai, Y.W. Lin, C.R. Kao, J. Mater. Res. 23, 250 (2008)

H.T. Ma, A. Kunwar, J.H. Sun, B.F. Guo, H.R. Ma, Scr. Mater. 107, 88 (2015)

Z.J. Zhang, M.L. Huang, Acta. Metall. Sin. 52, 592 (2017)

X.M. Li, F.L. Sun, H. Zhang, M. Liu, R. Fan, J. Alloys Compd. 739, 388 (2018)

J.Q. Huang, M.B. Zhou, S.B. Liang, X.P. Zhang, J. Mater. Sci. Mater. Electron. 29, 7651 (2018)

C.M. Chen, L.T. Chen, Y.S. Lin, J. Electron. Mater. 36, 168 (2007)

H.F. Zou, Q.K. Zhang, Z.F. Zhang, Mater. Sci. Eng. A 532, 167 (2012)

X. Zhao, M. Saka, M. Muraoka, M. Yamashita, H. Hokazono, J. Electron. Mater. 43, 4179 (2014)

J. Shen, Y.Y. Pu, H.G. Yin, D.J. Luo, J. Chen, J. Alloys Compd. 614, 63 (2014)

H. Gan, K.N. Tu, J. Appl. Phys. 97, 063514 (2005)

C.C. Wei, C. Chen, J. Appl. Phys. 88, 182105 (2006)

X. Gu, D. Yang, Y.C. Chan, B.Y. Wu, J. Mater. Res. 23, 2591 (2008)

B. Chao, S.H. Chae, X.F. Zhang, K.H. Lu, J. Im, P.S. Ho, Acta Mater. 55, 2805 (2007)

P. Kumar, J. Howarth, I. Dutta, J. Appl. Phys. 115, 044915 (2014)

Funding

This research was funded by the Natural Science Foundation of Guangxi Province (Grant Nos. AD19245093 and 2019GXNSFAA245059), Middle-aged and Young Teachers' Basic Ability Promotion Project of Guangxi (Grant No. 2019KY0221), GDAS Special Project of Science and Technology Development (Grant Nos. 2020GDASYL-20200402006 and 2022GDASZH-2022010109), and National Key Research and Development Program of China (Grant No. 2020YFE0205300).

Author information

Authors and Affiliations

Contributions

JH: Conceptualization, Methodology, Formal analysis, Data curation, Writing – original draft. XW: Methodology, Experiment, Data curation, Writing – original draft. JC: Methodology, Experiment. WW: Methodology, Experiment. YZ: Writing, Review & Editing. FL: Formal analysis, Supervision. BQ: Formal analysis, Supervision. HW: Formal analysis, Supervision.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Ethical approval

This article does not contain any studies with human tissues or animals performed by any of the authors.

Consent to participate

This research is not related to human subjects.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Huang, J., Wang, X., Chen, J. et al. Growth mechanisms of intermetallic compounds and Bi-rich layer in ball grid array structure Cu/Sn-58Bi/Cu solder joints during solid–solid and liquid–solid electromigration. J Mater Sci: Mater Electron 33, 10297–10313 (2022). https://doi.org/10.1007/s10854-022-08018-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-022-08018-x