Abstract

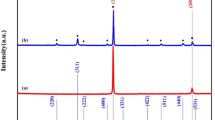

Fe3N/Fe soft magnetic composites (SMCs) are a kind of promising materials with excellent magnetic properties. In this work, Fe3N/Fe core-shell particles are prepared by gas nitriding and then pressed into Fe3N/Fe SMCs. The Fe3N phase increases with the nitriding time, resulting in the decrease of saturation magnetization and the increase of remanence and coercivity. The saturation magnetization and coercivity of the 5 h nitridated sample are 87.8 emu/g and 13.2Oe, respectively, and the product is identified to be pure Fe3N phase. The effective permeability firstly decreases and then increases with the nitridation time. The 5-h nitriding sample shows the best frequency stability, and its permeability decreases from 14.2 at 20 kHz to 4.3 at 590 kHz in a 4mT magnetic field. The core loss, especially eddy current loss, of Fe3N/Fe SMCs is obviously decreased with Fe3N content. The results show that the properties of soft magnetic composites at high frequency can be improved significantly by nitriding treatment.

Similar content being viewed by others

References

H. Shokrollahi, K. Janghorban, Soft magnetic composite materials (SMCs). J. Mater. Process. Technol. 189, 1–12 (2007). https://doi.org/10.1016/j.jmatprotec.2007.02.034

K.J. Sunday, M.L. Taheri, Soft magnetic composites: recent advancements in the technology. Met. Powder Rep. 72, 425–429 (2017). https://doi.org/10.1016/j.mprp.2016.08.003

M.M. Zhou, Y. Han, W.W. Guan, S.J. Han, Q.S. Meng, T.T. Xu, H.L. Su, X. Guo, Z.Q. Zou, F.Y. Yang, Y.W. Du, Magnetic properties and loss mechanism of Fe-6.5wt%Si powder core insulated with magnetic Mn-Zn ferrite nanoparticles. J. Magn. Magn. Mater. 482, 148–154 (2019). https://doi.org/10.1016/j.jmmm.2019.03.062

Z. Yao, Y. Peng, C. Xia, X. Yi, S. Mao, M. Zhang, The effect of calcination temperature on microstructure and properties of FeNiMo@Al2O3 soft magnetic composites prepared by sol-gel method. J. Alloys Compd. (2020). https://doi.org/10.1016/j.jallcom.2020.154345

C. Xia, Y. Peng, X. Yi, Z. Yao, Y. Zhu, G. Hu, Improved magnetic properties of FeSiCr amorphous soft magnetic composites by adding carbonyl iron powder. J. Non-Cryst Solids (2021). https://doi.org/10.1016/j.jnoncrysol.2021.120673

X. Peng, S. Yu, J. Chang, M. Ge, J. Li, T. Ellis, Y. Yang, J. Xu, B. Hong, D. Jin, H. Jin, X. Wang, H. Ge, Preparation and magnetic properties of Fe4N/Fe soft magnetic composites fabricated by gas nitridation. J. Magn. Magn. Mater. (2020). https://doi.org/10.1016/j.jmmm.2020.166407

W. Nie, T. Yu, Z. Wang, X. Wei, High-performance core-shell-type FeSiCr@MnZn soft magnetic composites for high-frequency applications. J. Alloys Compd. (2021). https://doi.org/10.1016/j.jallcom.2020.158215

Z.G. Luo, X.A. Fan, W.T. Hu, F. Luo, G.Q. Li, Y.W. Li, X. Liu, J. Wang, Controllable SiO2 insulating layer and magnetic properties for intergranular insulating Fe-6.5wt.%Si/SiO2 composites. Adv. Powder Technol. 30, 538–543 (2019). https://doi.org/10.1016/j.apt.2018.12.004

X. Fan, J. Wang, Z.Y. Wu, G.Q. Li, Core-shell structured FeSiAl/SiO2 particles and Fe3Si/Al2O3 soft magnetic composite cores with tunable insulating layer thicknesses. Mater. Sci. Eng. B-Adv 201, 79–86 (2015). https://doi.org/10.1016/j.mseb.2015.08.009

R. Koohkan, S. Sharafi, H. Shokrollahi, K. Janghorban, Preparation of nanocrystalline Fe-Ni powders by mechanical alloying used in soft magnetic composites. J. Magn. Magn. Mater. 320, 1089–1094 (2008). https://doi.org/10.1016/j.jmmm.2007.10.033

G. Zhang, G. Shi, W. Yuan, Y. Liu, Magnetic properties of iron-based soft magnetic composites prepared via phytic acid surface treatment. Ceram. Int. 47, 8795–8802 (2021). https://doi.org/10.1016/j.ceramint.2020.11.245

L. Ren, J. Zhao, S.-J. Wang, B.-Z. Han, Z.-M. Dang, Dielectric and magnetic properties of Fe@FexOy/epoxy resin nanocomposites as high-performance electromagnetic insulating materials. Compos. Sci. Technol. 114, 57–63 (2015). https://doi.org/10.1016/j.compscitech.2015.04.003

M.M. Dias, H.J. Mozetic, J.S. Barboza, R.M. Martins, L. Pelegrini, L. Schaeffer, Influence of resin type and content on electrical and magnetic properties of soft magnetic composites (SMCs). Powder Technol. 237, 213–220 (2013). https://doi.org/10.1016/j.powtec.2013.01.006

H. Shokrollahi, K. Janghorban, F. Mazaleyrat, M.L. Bue, V. Ji, A. Tcharkhtchi, Investigation of magnetic properties, residual stress and densification in compacted iron powder specimens coated with polyepoxy. Mater. Chem. Phys. 114, 588–594 (2009). https://doi.org/10.1016/j.matchemphys.2008.10.013

B. Yang, Z. Wu, Z. Zou, R. Yu, High-performance Fe/SiO2 soft magnetic composites for low-loss and high-power applications. J. Phys. D (2010). https://doi.org/10.1088/0022-3727/43/36/365003

S. Wu, A. Sun, Z. Lu, C. Cheng, X. Gao, Magnetic properties of iron-based soft magnetic composites with SiO2 coating obtained by reverse microemulsion method. J. Magn. Magn. Mater. 381, 451–456 (2015). https://doi.org/10.1016/j.jmmm.2015.01.030

B. Zhou, Y. Dong, L. Liu, L. Chang, F. Bi, X. Wang, Enhanced soft magnetic properties of the Fe-based amorphous powder cores with novel TiO2 insulation coating layer. J. Magn. Magn. Mater. 474, 1–8 (2019). https://doi.org/10.1016/j.jmmm.2018.11.014

A. Hossein Taghvaei, A. Ebrahimi, K. Gheisari, K. Janghorban, Analysis of the magnetic losses in iron-based soft magnetic composites with MgO insulation produced by sol–gel method. J. Magn. Magn. Mater. 322, 3748–3754 (2010). https://doi.org/10.1016/j.jmmm.2010.07.032

Y. Peng, Y. Yi, L. Li, J. Yi, J. Nie, C. Bao, Iron-based soft magnetic composites with Al2O3 insulation coating produced using sol–gel method. Mater. Design 109, 390–395 (2016). https://doi.org/10.1016/j.matdes.2016.07.097

A.H. Taghvaei, H. Shokrollahi, K. Janghorban, Properties of iron-based soft magnetic composite with iron phosphate–silane insulation coating. J. Alloys Compd. 481, 681–686 (2009). https://doi.org/10.1016/j.jallcom.2009.03.074

L. Qian, J. Peng, Z. Xiang, Y. Pan, W. Lu, Effect of annealing on magnetic properties of Fe/Fe3O4 soft magnetic composites prepared by in-situ oxidation and hydrogen reduction methods. J. Alloy Compd. 778, 712–720 (2019). https://doi.org/10.1016/j.jallcom.2018.11.184

G. Zhao, C. Wu, M. Yan, Enhanced magnetic properties of Fe soft magnetic composites by surface oxidation. J. Magn. Magn. Mater. 399, 51–57 (2016). https://doi.org/10.1016/j.jmmm.2015.09.054

W. Gu, X. Cui, J. Zheng, J. Yu, Y. Zhao, G. Ji, Heterostructure design of Fe3N alloy/porous carbon nanosheet composites for efficient microwave attenuation. J. Mater. Sci. Technol. 67, 265–272 (2021). https://doi.org/10.1016/j.jmst.2020.06.054

G.D. Cui, X.L. Wei, E.A. Olevsky, R.M. German, J.Y. Chen, Preparation of high performance bulk Fe-N alloy by spark plasma sintering. Mater. Design 90, 115–121 (2016). https://doi.org/10.1016/j.matdes.2015.10.122

J. Xiao, J.W. Chen, Z.Q. Ou, J.H. Lai, T.W. Yu, Y. Wang, N-doped carbon-coated Fe3N composite as heterogeneous electro-Fenton catalyst for efficient degradation of organics. Chin. J Catal 42, 953–962 (2021). https://doi.org/10.1016/S1872-2067(20)63719-6

W. Huang, X. Wang, Preparation and Properties of ε-Fe3N-Based Magnetic Fluid. Nanoscale Res. Lett. 3, 260–264 (2008). https://doi.org/10.1007/s11671-008-9148-y

N. Zhao, W. Wang, X. Lei, Z. Ye, X. Chen, H. Ding, H. Yang, Synthesis, structure and magnetic properties of Fe3N nanoparticles. J. Mater. Sci.: Mater. Electron. 28, 15701–15707 (2017). https://doi.org/10.1007/s10854-017-7460-y

X. Tan, S. Wang, Y. Chen, Y. Zhou, Z. Li, Design, preparation and characterization of iron nitride magnetic abrasives. J. Alloy Compd. 774, 443–450 (2019). https://doi.org/10.1016/j.jallcom.2018.09.389

Z. Gao, L. Li, Y. Ge, Q. Chen, Enhanced AC magnetic properties of Fe-based soft magnetic composites coated with an electrically insulated SiO2–ZrO2 layer. J. Mater. Sci.: Mater. Electron. 32, 14944–14955 (2021). https://doi.org/10.1007/s10854-021-06046-7

H. Sun, C. Wang, J. Wang, M. Yu, Z. Guo, Fe-based amorphous powder cores with low core loss and high permeability fabricated using the core-shell structured magnetic flaky powders. J. Magn. Magn. Mater. (2020). https://doi.org/10.1016/j.jmmm.2020.166548

Acknowledgements

The authors acknowledge the support and guidance provided by College of Materials and Chemistry, China Jiliang University, Hangzhou 310018, China.

Funding

This work was supported by Zhejiang Province Public Welfare Technology Application Research Project (LGG22E010001, LGG19E010002), Natural Science Foundation of Zhejiang Province (LY20E020011), Key R&D Program of Zhejiang Province of China (2020C01008), and National Natural Science Foundation of China (U1809216).

Author information

Authors and Affiliations

Contributions

MG contributed to resources, writing - original draft, and writing - review & editing. XP contributed to project administration, supervision, and funding acquisition. JL contributed to writing - review & editing and funding acquisition. YY, HG, and HJ contributed to funding acquisition. JX contributed to resources. BH contributed to resources and writing - review & editing. DJ, TE, and XW contributed to writing - review & editing.

Corresponding authors

Ethics declarations

Conflict of interest

The authors have no relevant financial or non-financial interests to disclose.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Ge, M., Peng, X., Li, J. et al. Effects of gas nitridation on microstructures and magnetic properties of Fe3N/Fe soft magnetic composites. J Mater Sci: Mater Electron 33, 10287–10296 (2022). https://doi.org/10.1007/s10854-022-08017-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-022-08017-y