Abstract

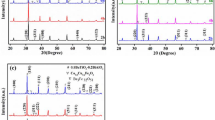

In this work, we used the single-pot synthesis methods to prepare the uniform and pure CFO/BCZT composite particles with different mass ratios (1:3, 1:4, 1:5, 1:6, 1:7) at first. Then these particles were sintered into the composite ceramics successfully at 1200 °C. The surface morphology, dielectric, leakage, ferroelectric, and ferromagnetic properties of composite ceramics were studied systematically. All diffraction peaks correspond to the standard card and the XRD pattern shows no impurity peaks. Then the grain size of composite powders is in the range of 30–40 nm. SEM results show that the crystal grains of the ferromagnetic and ferroelectric phases are easy to agglomerate. The dielectric properties of composite ceramics are mainly related to the mass ratio of the ferroelectric phase. As the content of BCZT improves, the dielectric constant slowly increases, and the dielectric loss slowly reduces at high frequency. The saturated polarization (Ps), residual polarization (Pr), and coercive field (Ec) of the 1:4 reach 3.03 µC/cm2, 1.14 µC/cm2, and 8.91 kV/cm, respectively. The leakage current and ferromagnetism of composite ceramics could be improved by adjusting the mass ratio. In addition, the frequency could well change the magnetoelectric coupling coefficient (αME) of the sample. The maximum magnetoelectric coupling coefficient of the 1:3 is 92.24 mV/cm Oe.

Similar content being viewed by others

Data availability

The data presented in this study are available on request from the corresponding author. The data are not publicly available due to privacy restriction.

References

V.A. Khomchenko, D.V. Karpinsky, A.L. Kholkin et al., J. Appl. Phys. 108, 074109 (2010)

S. Sharma, J.M. Siqueiros, O.R. Herrera, J. Alloy. Compd. 853, 156979 (2021)

R.L. Gao, H.W. Yang, Y.S. Chen et al., Appl. Phys. Lett. 104, 031906 (2014)

X.J. He, B. Liu, Y.B. Pan, J.R. Lin, Ferroelectrics 514, 158–164 (2017)

M. Geramilla, R. Balakrishnan, S.T. Natarajan et al., Appl. Phys. A 125, 1 (2019)

M.A. Rafiq, T.U. Zaman, H.A. Ishfaq et al., Ceram. Int. 46, 2489–2499 (2020)

K.C. Verma, N. Goyal, R.K. Kotnala, Physica B 554, 9–16 (2019)

V.R. Monaji, S.D. Kumar et al., Ceram. Int. 44, 4298–4306 (2018)

P. Galizia, C. Baldisserri, E. Mercadelli, C. Capiani, C. Galassi et al., Materials 13, 2592 (2020)

Y. Liu, G.W. Xu, Y.Y. Xie, H. Lv, C.Y. Huang, Y.W. Chen et al., Ceram. Int. 44, 9649–9655 (2018)

C.Y. Li, R.C. Xu, R.L. Gao et al., Mater. Chem. Phys. 249, 123144 (2020)

L.K. Pradhan, R. Pandey, R. Kumar, M. Kar, J. Appl. Phys. 123, 074101 (2018)

N. Buatip, M. Dhanunjaya, P. Amonpattaratkit et al., Radiat. Phys. Chem. 172, 108770 (2020)

P. Pomyai, D. Munthala, T. Sonklin et al., J. Eur. Ceram. Soc. 41, 2497–2505 (2021)

Y. Huan, X.H. Wang, J. Fang, L.T. Li, J. Eur. Ceram. Soc. 34, 1445–1448 (2014)

A. Guzu, C.E. Ciomaga, M. Airimioaei et al., J. Alloy. Compd. 796, 55–64 (2019)

G.J. Li, X.M. Li, Q.X. Zhu, J.L. Zhao, X.D. Gao, CrystEngComm 21, 6545–6551 (2019)

Q.W. Zhang, W. Cai, C. Zhou et al., Appl. Phys. A 125, 1–9 (2019)

S.A. Raza, S.U. Awan, S. Hussain, S.A. Shah et al., J. Appl. Phys. 128, 124101 (2020)

Q.T. Li, Q.W. Zhang, W. Cai et al., Mater. Chem. Phys. 252, 123242 (2020)

J. Kulawik, D. Szwagierczak, P. Guzdek, J. Magn. Magn. Mater. 324, 3052–3057 (2012)

I. Coondoo, N. Panwar, D. Alinkin et al., Acta Mater. 155, 331–342 (2018)

G. Kotnana, F. Sayed, D.C. Joshi et al., J. Magn. Magn. Mater. 511, 166792 (2020)

P. Acharyya, P.K. Samanta, A. Sarkar et al., Nanoscale 11, 4001–4007 (2019)

N. Wang, S. Wang, G. Liu et al., Mat. Sci. Eng. A 806, 140842 (2021)

H. Istgaldi, M.S. Asl, P. Shahi et al., Ceram. Int. 46, 2923–2930 (2020)

S. Sharma, J.M. Siqueiros, G. Srinet et al., J. Alloy. Compd. 732, 666–673 (2018)

R.L. Gao, Q.M. Zhang, Z.Y. Xu et al., Compos. Part B-Eng. 166, 204–212 (2019)

T. Cheng, L.F. Xu, P.B. Qi et al., J. Alloy. Compd. 602, 269–274 (2014)

A. Barua, S.K. Dey, S.K. Sabyasachi, S. Kumar, J. Alloy. Compd. 854, 157217 (2021)

S. Singh, N. Kumar, R. Bhargava et al., J. Alloy. Compd. 587, 437–441 (2014)

P.Q. Mantas, J. Eur. Ceram. Soc. 19, 2079–2086 (1999)

V.R. Monaji, J.P. Paul, N.S. Sowmya et al., Ceram. Int. 42, 17827–17833 (2016)

Z.H. Wang, R.L. Gao, G. Cheng et al., Ceram. Int. 46, 9154–9160 (2020)

Y.Z. Xue, R.C. Xu, Z.H. Wang et al., J. Electron. Mater. 48, 4806–4817 (2019)

Z.J. Wang, Y. Chen, J. Alloy. Compd. 854, 157270 (2021)

M. Hashim, Alimuddin, S. Kumar et al., J. Alloy. Compd. 511, 107–114 (2012)

H. Yang, G. Zhang, Y. Lin, J. Alloy. Compd. 644, 390–397 (2015)

J. Wei, Y. Liu, X.F. Bai et al., Ceram. Int. 42, 13395–13403 (2016)

G.W. Pabst, L.W. Martin, Y.H. Chu, R. Ramesh, Appl. Phys. Lett. 90, 072902 (2007)

M.A. Khan, T.P. Comyn, A.J. Bell, Appl. Phys. Lett. 92, 072908 (2008)

Y.H. Chen, D.H. Chen, L.F. Meng et al., R. Soc. Open sci. 7, 191822 (2020)

Y.R. Wang, Y.P. Pu, Y.C. Tian et al., J. Alloy. Compd. 696, 1307–1313 (2017)

S. Smail, M. Benyoussef, K. Taïbi et al., Mater. Chem. Phys. 252, 123462 (2020)

R.V. Krishnaiah, A. Srinivas, S.V. Kamat, T. Karthik, S. Asthana, Ceram. Int. 40, 7799–7804 (2014)

J.D. Bobić, M. Ivanov, N.I. Ilić et al., Ceram. Int. 44, 6551–6557 (2018)

A. Franco, F.C. Silva, Appl. Phys. Lett. 96, 172505 (2010)

M. Atif, M. Nadeem, J. Alloy. Compd. 623, 447–453 (2015)

S.M. Mane, A.R. Nimbalkar, H. Kim et al., J. Alloy. Compd. 849, 156599 (2020)

M.A. Radmanesh, S.A. Seyyed Ebrahimi, J. Magn. Magn. Mater. 324, 3094–3098 (2012)

H. Palneedi, S. Na, G. Hwang et al., J. Alloy. Compd. 765, 764–770 (2018)

S.R. Wadgane, S.T. Alone, A. Karim et al., J. Magn. Magn. Mater. 471, 388–393 (2019)

Z.Q. Zheng, P. Zhou, Y. Liu et al., J. Alloy. Compd. 818, 152871 (2020)

Acknowledgements

Authors are thankful for financial assistance provided by the Natural Science Foundation of China (Grant No. 52074232).

Funding

This work was financially supported by the Natural Science Foundation of China (No. 52074232).

Author information

Authors and Affiliations

Contributions

CL and YL involved in conceptualization; CL, JZ, and YY performed data curation; HZ, XY, and QZ contributed in investigation; YL participated in project administration; CL and YL took part in writing—review & editing. All authors have read and agreed to the version of the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Li, C., Zhang, J., Yuan, Y. et al. A simple and low-cost method of preparing CoFe2O4/Ba0.85Ca0.15Zr0.1Ti0.9O3 composite ceramics. J Mater Sci: Mater Electron 33, 3757–3773 (2022). https://doi.org/10.1007/s10854-021-07567-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-021-07567-x