Abstract

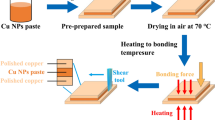

Cu-Cu bonding is always conducted at high temperature and high pressure in reductive atmosphere to eliminate the influence caused by oxidation. Herein, a novel low-pressure sinterable Cu nanoparticle (Cu-NPs) paste was developed using Cu Metal Organic Decomposition (MOD) ink as solvent and surface modifier. The Cu MOD ink in paste introduced in Cu nanoparticle paste not only eliminated the surface oxidation of Cu-NPs, but also modified Cu-NPs with Cu atoms due to the thermal decomposition during sintering process. As a result, robust Cu sinter joints for die-attachment could be realized at a low pressure of 0.4 MPa in non-reductive nitrogen atmosphere. Using the paste with 20 wt.% Cuf addition in solvent, a relative high shear strength of 17.1 MPa could be achieved at 300 °C, which is about 3.8 times higher than that sintered without MOD ink (4.5 MPa). When bonding temperature rose to 350 °C, even higher shear strength over 20 MPa was obtained. The bonding strength was comparable to the traditional Pb-5Sn solder alloy, promising its industrial potential.

Similar content being viewed by others

References

Z. Liu, B. Li, F.C. Lee, Q. Li, IEEE Trans. Ind. Electron. 64, 9114 (2017)

K. Shenai, IEEE Trans Electron Devices 62, e248 (2015)

F. Roccaforte, P. Fiorenza, G. Greco, R. Lo Nigro, F. Giannazzo, F. Iucolano, M. Saggio, Microelectron. Eng. 187, e66 (2018)

M. Shur, Solid-State Electron. 155, 65 (2019)

A.Q. Huang 2016 IEEE Int Electron Devices Meet pp 20.1. 1

H. Zhang, Y. Gao, J. Jiu, K. Suganuma, J. Alloys Compd. 696, 123 (2017)

H. Zhang, C. Hen, J. Jiu, S. Nagao, K. Suganuma, J. Mater. Sci.: Mater. Electron. 29, 8854 (2018)

Z. Zhang, C. Chen, Y. Yang, H. Zhang, D. Kim, T. Sugahara, S. Nagao, K. Suganuma, J. Alloys Compd. 780, 435 (2019)

S. Zhang, Q. Wang, T. Lin, P. Zhang, P. He, K.-W. Paik, J. Manuf. Processes. 62, 546 (2021)

D. Yamagiwa, T. Matsuda, H. Furusawa, K. Sato, H. Tatsumi, T. Sano, Y. Kashiba, A. Hirose, J. Mater. Sci.: Mater. Electron. 32, 19031 (2021)

Y. Zuo, S. Carter-Searjeant, M. Green, L. Mills, S.H. Mannan, Mater. Lett. 276, e128260 (2020)

Y. Mou, Y. Peng, Y.R. Zhang, H. Cheng, M.X. Chen, Mater. Lett. 227, 179 (2018)

Y. Kobayashi, T. Shirochi, Y. Yasuda, T. Morita, J. Int. Adhes. Adhes. 33, 50 (2012)

Jo. J.-L, Anai. K, Yamauchi. S, Hattori. T, Sakaue. T 2020 IEEE Electron. Compon. Technol. Conf. pp 749

H. Nishikawa, T. Hirano, T. Takemoto, N. Terada, Open Surface Science Journal 3, 60 (2011)

J.-W. Yoon, J.-H. Back, Materials. 11(11), e2105 (2018)

H. Nishikawa, X. Liu, S. He, Int. Microelectron Assem Packag Soc. 2017, e000202 (2017)

Y. Farraj, A. Smooha, A. Kamyshny, S. Magdassi, A.C.S. Appl, Mater. Interfaces. 9, 8766 (2017)

Y. Farraj, M. Grouchko, S. Magdassi, Chem. Commun. 51, 1587 (2015)

K.-M. Huang., H. Tsukamoto, Y. Yong, H.-L. Chiu, N. Mai Thanh, T. Yonezawa, Y.-C. Liao 2017 RSC Adv. 7: e25095

S. Kang, K. Tasaka, J.H. Lee, A. Yabuki, Chem. Phys. Lett. 763, e138248 (2021)

A. Yabuki, S. Kawahara, S. Kang, I.W. Fathona, J. Mater. Sci. Eng. B. 262, e114743 (2020)

W. Li, H. Zhang, Y. Gao, J. Jiu, C.-F, Li, C. Chen, D. Hu, Y. Goya, Y. Wang, H. Koga, S. Nagao, K. Suganuma 2017 J. Mater. Chem. C. 5: e1155

E. Ide, A. Hirose, K.F. Kobayashi, Mater. Trans. 47, 211 (2006)

Y. Shi, W. Fang, Z. Xia, Y. Lei, F. Guo, X. Li, J. Mater. Sci.: Mater. Electron. 21, 875 (2010)

Y. Gao, W. Li, C. Chen, H. Zhang, J. Jiu, C.-F. Li, S. Nagao, K. Suganuma, Mater. Des. 160, 1265 (2018)

Y. Dong, Z. Lin, X. Li, Q. Zhu, J.-G. Li, X. Sun, J. Mater. Chem. C. 6, 6406 (2018)

K.-M. Huang, H. Tsukamoto, Y. Yong, H.-L. Chiu, N. Mai Thanh, T. Yonezawa, Y.-C. Liao 2017 RSC Adv. 7: e25095

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Gao, Y., Xiao, Yb., Liu, ZQ. et al. Low pressure Cu-Cu bonding using MOD ink-modified Cu particle paste for die-attachment of power semiconductors. J Mater Sci: Mater Electron 33, 3576–3585 (2022). https://doi.org/10.1007/s10854-021-07551-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-021-07551-5