Abstract

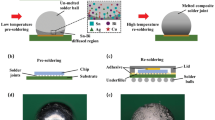

In order to control the interfacial intermetallics of the commonly used soldering joint in the electronics packaging products, copper and nickel-plated copper were selected as the substrates, SAC305 was selected as the solder, and a series of experiments were conducted. The pure copper was plated with nickel and then the nickel-plated copper substrate was heat-treated before reflow soldering. Effects of substrate heat treatment on reflow soldering and aging of the soldered joints were studied. The results show that the heat treatment of nickel-plated copper substrate before reflow soldering can enhance the adhesion between the substrate and the plated coating and it can inhibit the growth of interfacial intermetallic compound (IMC). In the aging process, the IMC layer thickness of the soldered joint without heat treatment on the substrate before reflow is thicker than that of the soldered joint with heat treatment before reflow. The IMC growth rate of the interfacial layer of the soldered joint without heat treatment on the substrate before reflow is 5.854 × 10–17 m2 s−1; the IMC growth rate of the interfacial layer of the soldered joint with the substrate heat-treated before reflow soldering is 3.193 × 10–17 m2 s−1. In the shear test, the shear strength of the solder joints with heat treatment on the substrate before reflow soldering is higher than that of the solder joints without heat treatment before reflow soldering.

Similar content being viewed by others

Data availability

The authors declare that data supporting the findings of this study are available within the article.

References

W.J. Plumbridge, Solders in electronics. J. Mater. Sci. 31(10), 2501–2514 (1996)

R.A. Islam, B.Y. Wu, M.O. Alam, Y.C. Chan, W. Jillek, Investigations on microhardness of Sn-Zn based lead-free solder alloys as replacement of Sn-Pb. J. Alloys Compd. 392(1–2), 149–158 (2005)

H. Ma, J.C. Suhling, A review of mechanical properties of lead-free solders for electronic packaging. J. Mater. Sci. 44(5), 1141–1158 (2009)

M. Abtew, G. Selvaduray, Lead-free solders in microelectronics. J. Mater. Sci. Eng. 27(5–6), 95–141 (2000)

H.R. Kotadia, P.D. Howes, S.H. Mannan, A review: on the development of low melting temperature Pb-free solders. J. Microelectron. Reliab. 54(6–7), 1253–1273 (2014)

S. Li, X.X. Wang, Z.Y. Liu, Y.T. Jiu, S.Y. Zhang, J.F. Geng, X.M. Chen, S.J. Wu, P. He, W.M. Long, Corrosion behavior of Sn-based lead-free solder alloys: a review. J. Mater. Sci. 31(12), 9076–9090 (2020)

S. Chellvarajoo, M.Z. Abdullah, Microstructure and mechanical properties of Pb-free Sn-3.0Ag-0.5Cu solder pastes added with NiO nanoparticles after reflow soldering process. J. Mater. Des. 90, 499–507 (2016)

S. Cheng, C.M. Huang, M. Pecht, A review of lead-free solders for electronics applications. J. Microelectron. Reliab. 75, 77–95 (2017)

G. Zeng, S.B. Xue, L. Zhang, L.L. Gao, W. Dai, J.D. Luo, A review on the interfacial intermetallic compounds between Sn-Ag-Cu based solders and substrates. J. Mater. Sci. 21(5), 421–440 (2010)

K.N. Tu, K. Zeng, Tin-lead (SnPb) solder reaction in flip chip technology. J. Mater. Sci. Eng. R 34(1), 1–58 (2001)

J.W. Yoon, C.B. Lee, S.B. Jung, Growth of an intermetallic compound layer with Sn-35Ag-5Bi on Cu and Ni-P/Cu during aging treatment. J. Electron. Mater. 32(11), 1195–1202 (2003)

Z. Mao, W.W. Zhang, J. Li, S.J. Dong, X. Lin, X.D. Jian, P. Wu, The obstruction effect of Ni layer on the interdiffusion of Cu substrate and Sn solder: a theoretical investigation. J. Electron. Mater. 49(11), 6559–6571 (2020)

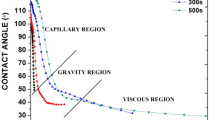

Y.L. Li, Z.L. Wang, W.F. Long, M. Lei, X.W. Hu, Wetting kinetics and spreading phenomena of Sn-35Bi-1Ag solder on different substrates. J. Mater. Sci. 29(16), 13914–13924 (2018)

S.H. Kim, J.Y. Kim, J. Yu, Investigation of electroplated Ni and Ni-Cu alloy UBM (Under Bump Metallurgy) with lead-free solders for flip chip packages. J. SPIE. Proc. Ser. 4931, 251–255 (2002)

J.W. Choi, H.S. Cha, T.S. Oh, Shear strength and aging characteristics of 63Sn37Pb solder bumps with various solder ball and pad sizes. J. Met. Mater. Int. 9(3), 273–278 (2003)

M. Li, Applications of electroplating technology in electronic packaging. J. Electroplat. Finish. 24(1), 44–49 (2005)

J.W. Yoon, S.W. Kim, S.B. Jung, IMC morphology, interfacial reaction and joint reliability of Pb-free Sn-Ag-Cu solder on electrolytic Ni BGA substrate. J. Alloys Compd. 392(1–2), 247–252 (2005)

C.P. Huang, C. Chen, C.Y. Liu, S.S. Lin, Metallurgical reactions of Sn-35Ag solder with various thicknesses of electroplated Ni/Cu under bump metallization. J. Mater. Res. 20(10), 2772–2779 (2005)

X. Bi, X. Hu, Q. Li, Effect of Co addition into Ni film on shear strength of solder/Ni/Cu system: experimental and theoretical investigations. J. Mater. Sci. Eng. A. 788, 139589 (2020)

J.F. Rohan, G. O’Riordan, J. Boardman, Selective electroless nickel deposition on copper as a final barrier/bonding layer material for microelectronics applications. J. Appl. Surf. Sci. 185, 289 (2002)

Y.L. Li, Z.L. Wang, X.W. Li, X.W. Hu, M. Lei, Growth behavior of IMCs layer of the Sn–35Bi–1Ag on Cu, Ni–P/Cu and Ni–Co–P/Cu substrates during aging. J. Mater. Sci. 30(2), 1519–1530 (2019)

J. Sudagar, J. Lian, W. Sha, Electroless nickel, alloy, composite and nano coatings: a critical review. J. Alloys Compd. 571(31), 183–204 (2013)

J.W. Choi, G.H. Hwang, W.K. Han, S.G. Kang, Phase transformation of Ni-B, Ni-P diffusion barrier deposited electrolessly on Cu interconnect. J. Appl. Surf. Sci. 253(4), 2171–2178 (2006)

B.Z. Song, Y.P. Zhao, Z.S. Cai, Study on the process hydrazine reduction of electroless pure nickel plating. J. Surf. Technol. 42(6), 48–51 (2013)

H. Kahar, Z.A.A. Malek, S.R.A. Idris, M. Ishak, Intermetallic growth and shear strength of SAC305/EN-boron. J. Solder. Surf. Mt. Technol. 28(3), 141–148 (2016)

J. Yoon, S. Kim, S. Jung, Effect of reflow time on interfacial reaction and shear strength of Sn-07Cu solder/Cu and electroless Ni-P BGA joints. J. Alloys Compd. 385(1–2), 192–198 (2004)

M.O. Alam, Y.C. Chan, K.C. Kung, Reliability study of the electroless Ni-P layer against solder alloy. J. Microelectron. Reliab. 42(7), 1065–1073 (2002)

K. Zeng, K.N. Tu, Six cases of reliability study of Pb-free solder joints in electronic packaging technology. J. Mater. Sci. Eng. R 38(2), 55–105 (2002)

A. Kumar, Z. Chen, S.G. Mhaisalkar, C.C. Wong, P.S. Teo, V. Kripesh, Effect of Ni-P thickness on solid-state interfacial reactions between Sn-35Ag solder and electroless Ni-P metallization on Cu substrate. J. Thin. Solid. Films. 504(1/2), 410–415 (2006)

G. Opposits, S. Szabó, D.L. Beke, Z. Guba, I.A. Szabo, Diffusion-induced bending of Cu-Ni thin sheet diffusion couples. J. Scr. Mater. 39(7), 977–983 (1998)

S.M. Schwarz, B.W. Kempshall, L.A. Giannuzzi, Effects of diffusion induced recrystallization on volume diffusion in the copper-nickel system. J. Acta Mater. 51(10), 2765–2776 (2003)

Z. Wang, L. Fang, I. Cotton, R. Freer, Ni-Cu interdiffusion and its implication for ageing in Ni-coated Cu conductors. J. Mater. Sci. Eng. B 198, 86–94 (2015)

W.C. Luo, C.E. Ho, J.Y. Tsai, Y.L. Lin, C.R. Kao, Solid-state reactions between Ni and Sn-Ag-Cu solders with different Cu concentrations. J. Mater. Sci. Eng. A 396, 385–391 (2005)

X.P. Li, M.B. Zhou, J.M. Xia, X. Ma, X.P. Zhang, Effect of the cross-interaction on the formation and evolution of intermetallic compounds in Cu (Ni)/Sn-Ag-Cu/Cu (Ni) BGA structure solder joints. J. Acta. Metall. Sin. 47(5), 611–619 (2011)

J.W. Yoon, B.I. Noh, J.H. Yoon, H.B. Kang, S.B. Jung, Sequential interfacial intermetallic compound formation of Cu6Sn5 and Ni3Sn4 between Sn-Ag-Cu solder and ENEPIG substrate during a reflow process. J. Alloys Compd. 509(9), L153–L156 (2011)

X.W. Hu, T. Xu, X.X. Jiang, Y.L. Li, Interfacial reaction and IMCs growth behavior of Sn30Ag05Cu/Ni solder bump during aging at various temperatures. J. Mater. Sci. 27(5), 4245–4252 (2016)

C.P. Lin, C.M. Chen, Y.W. Yen, Enhanced growth of the Cu6Sn5 phase in the Sn/Ag/Cu and Sn/Cu multilayers subjected to applied strain. J. Alloys Compd. 591, 297–303 (2014)

X. Yu, Y.L. Li, X.W. Hu, R.H. Zhang, Study of interfacial microstructure of Cu/Sn58Bi/Cu solder joints with annealed Cu. J. Trans. China Weld. Inst. 36(10), 29–32 (2014)

X.W. Hu, T. Xu, L.M. Keer, Y.L. Li, X.X. Jiang, Microstructure evolution and shear fracture behavior of aged Sn3Ag05Cu/Cu solder joints. J. Mater. Sci. Eng. A 673, 167–177 (2016)

J. Shen, M. Zhao, P. He, Y. Pu, Growth behaviors of intermetallic compounds at Sn-3Ag-05Cu/Cu interface during isothermal and non-isothermal aging. J. Alloys Compd. 574, 451–458 (2013)

T. Xu, X.W. Hu, J.Y. Li, Q.L. Li, Fracture behavior and mechanical strength of sandwich structure solder joints with Cu–Ni(P) coating during thermal aging. J. Mater. Sci. 31, 3876–3889 (2020)

Acknowledgements

This work was sponsored by the Science and Technology Innovation High Level Talent Project of Double Thousand Plan of Jiangxi Province (jxsq2019201048) and the National Natural Science Foundation of China (No. 52065043).

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation, data collection, and analysis were performed by Yulong Li, Xiang Deng, Min Lei, Xuewen Li, and Hua Ouyang. The first draft of the manuscript was written by Yulong Li and Xiang Deng, and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Li, Y., Deng, X., Lei, M. et al. Enhancing the properties of the SAC305-soldered joint: heat treatment of the nickel-plated copper substrate before reflow soldering. J Mater Sci: Mater Electron 33, 3535–3545 (2022). https://doi.org/10.1007/s10854-021-07545-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-021-07545-3