Abstract

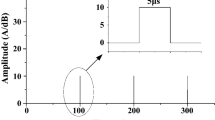

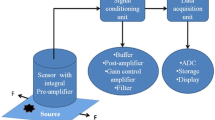

An epoxy-based acoustic emission sensor with low secondary reflection, high precision, and strong corrosion resistance was prepared by using the acoustic characteristics of different combinations of sensing element, matching layer, and backing layer. A simple calibration system for acoustic emission sensors is set up, and the static and dynamic characteristics of the sensor are tested. The experimental results show that the static and dynamic characteristics of the sensor are obtained by analyzing the characteristic parameters of the acoustic emission signal. In this static characteristic, sensitivity refers to the change in acoustic emission energy value caused by every 1 mm change in the falling distance of the zirconia ball, which is represented by the symbol E/mm. The linear error of the sensor is 16.5%, the sensitivity is 444.05 E/mm, the return error is 11.2%, and the non-repeating error is 19%. In order to evaluate the characteristics of signal superposition, the concept of signal superposition error value (ΔHt) is proposed based on error value between the sum of each impact component and the total impact quantity. The signal stacking property of the epoxy-based acoustic emission sensor is tested by using this index, and calculated ΔHt value is 0.059. This method can easily calibrate the acoustic emission sensor and provide a new basis for the accuracy of information received by the sensor. It is also found that the secondary reflexion signal of the polymer acoustic emission sensor is smaller, the resonant frequency is lower, and it has better corrosion resistance to rain water.

source distance

Similar content being viewed by others

References

J. Yu, P. Ziehl, F. Matta, A. Pollock, Constr. Steel Res. 86, 85–91 (2013)

N. Collier, P. Debreyne, G. Delaplace, B. Chen et al., Ultrasonics 89, 187–194 (2018)

P. Marina, T. Martinb, D.L. Tunnicliffeb, Sens. Actuators A. 99(3), 236–243 (2001)

H.L. Dunegan, D.O. Harris, C.A. Harris, Eng. Fract. Mech. 1, 105–110 (1968)

H.L. Dunegan, D.O. Harris, J. Ultrason. 7(3), 160–166 (1969)

E. Caso, F. Alfonso, P. Garcia et al., Appl. Acoust. 159, 107092 (2020). https://doi.org/10.1016/j.apacoust.2019.107092

M. Hamel, A. Addali, D. Mba et al., Appl. Acoust. 79, 42–46 (2016). https://doi.org/10.1016/j.apacoust.2013.12.005

B.J. Wright, S. Grigg, A.S. Bergsaker et al., Clin. Biomech. 76, 105026 (2020). https://doi.org/10.1016/j.clinbiomech.2020.105026

H. Pan, M. Huang, Constr. Build. Mater. 254, 119307 (2020)

M.S.H. Bhuiyan, I.A. Bhuiyan, M. Dahari, Y. Nukman, Measurement 92, 208–217 (2016)

W. Zhang, H. Jia, G. Gao, X. Cheng, P. Du, D. Xv, Appl. Acoust. 156, 387–393 (2019)

R. Goldaran, A. Turer, K. Mehdi, Constr. Build. Mater. 242, 118–123 (2020)

J.B. Liu, A.X. Guo, H. Li et al., J. Fluids Struct. 78, 197–214 (2018)

D. Xiao, Z. Zhang, H. Ren, Advances in Acoustic Emission Technology (Springer, New York, 2015), pp. 33–45

H. Hatano, E. Mori, Acoust. Soc. Am. 59, 344–349 (1976)

H. Hatano, T. Chaya, S. Watanabe, K. Jinbo, Ultra Ferroe. Freq. Control 45, 1221–1228 (1998)

G.C. McLaskey, S.D. Glaser, Nondestruct. Eval. 31, 157–168 (2012)

B. Burks, M.A. Hamstad, Compos. Struct. 117, 411–422 (2014)

J. Kober, Z. Prevorovsky, M. Chlada, Sens. Actuators A Phys. 240, 50–56 (2016)

G.R. Markus, A. Markus, Sens. Actuators 269, 294–307 (2018)

J. Yang, W. Yang, W. Chen et al., Prog. Polym. Sci. 109, 101289 (2020). https://doi.org/10.1016/j.progpolymsci.2020.101289

C. Wu, Y. Pan, T. Ueda, Constr. Build Mater. 174, 537–546 (2018)

Y. Xi, B. Li, L. Gao, T. Tang, H. Liao, Appl. Acoust. 134, 131–137 (2018)

J. Weiss, E. Jondeau, A. Giani et al., Sens. Actuators 265, 211–216 (2017)

Funding

This work was awarded by the National Natural Science Foundation of China [Grant Numbers U1806221, 51208228], the innovative team projects of institutions of higher learning, piezoelectric composite materials and engineering health monitoring [Grant Number 2019 GXRC017].

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Guo, R., Huang, S. & Liu, F. Study on preparation and simple calibration system of acoustic emission sensor based on epoxy resin. J Mater Sci: Mater Electron 33, 3348–3360 (2022). https://doi.org/10.1007/s10854-021-07534-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-021-07534-6