Abstract

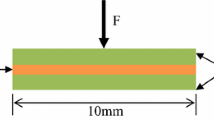

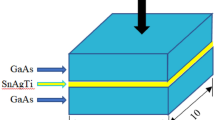

Low-temperature active bonding of silicon carbide substrate using Sn3.5Ag4Ti(Ce,Ga) active solder filler was carried out at 250 °C and 420 °C in air, respectively. The microstructure of the interface, the element distribution, and the new compounds formed at the interface had been investigated. The obvious segregation of titanium at the silicon carbide (SiC)/Sn3.5Ag4Ti(Ce,Ga) interface was observed for both soldering temperatures, in which the segregation rate at 420 °C is faster than that at 250 °C, because the diffusion coefficient of Ti is an exponential function of temperature. Results of transmission electron microscope analysis show that the reactants at the interface of SiC/Sn3.5Ag5Ti(Ce,Ga) of the joint soldered at 250 °C for 60 min were not observed although the segregation of Ti existed at the boundary. However, the TiC, Ti5Si3, and TiSi2 were found to be discontinuously formed at the interface for the joints soldered at 420 °C for 30 min. The work of adhesion of Ti on the surface of SiC is calculated, which might be inferred that the joining could be accomplished by chemical adsorption of titanium at the SiC/Sn3.5Ag4Ti(Ce,Ga) interface, regardless of whether an interfacial reaction layer is formed or not. The shear strength of the joints soldered at 420 °C is higher than that at 250 °C. This indicates that the formation of the reaction products plays a critical role to obtain more reliable bond between SiC and Sn3.5Ag4Ti(Ce,Ga), although it is not a necessary condition to realize bonding with reasonable strength.

Similar content being viewed by others

Data availability

The data that support the finding of this study are available from the corresponding author upon reasonable request.

Code availability

Not applicable.

References

L. Wu, L. Zhu, W. Guo, S. Sun, W. Niu, J. Xue, J. Zhai, H. Ma, R. Lin, H. Lin, K. Plucknett, Y. Liao, T. Liu, Q. Ren, J. Eur. Ceram. Soc. 41, 225–232 (2021)

X. Song, Z. Chen, S. Hu, X. Duan, Y. Lei, C. Niu, J. Feng, J. Am. Ceram. Soc. 103, 912–920 (2019)

F. Mu, Y. Wang, R. He, T. Suga, Materialia 3, 12–14 (2018)

G. Lyu, Y. Wang, J. Wei, Z. Zheng, J. Sun, L. Zhang, K.J. Chen, IEEE T. Power Electron. 35, 9669–9679 (2020)

Y. Feng, H. Sun, X. Yang, K. Liu, J. Zhang, J. Shen, D. Liu, Z. Cai, F. Xu, N. Tang, T. Yu, X. Wang, W. Ge, B. Shen, Appl. Phys. Lett. 118, 052104 (2021)

X. Dai, J. Cao, Z. Chen, X. Song, J. Feng, Ceram. Int. 42, 6319–6328 (2016)

X. Dai, J. Cao, Y. Tian, Z. Chen, X. Song, J. Feng, Mater. Charact. 118, 294–301 (2016)

M. Singh, R. Asthana, N. Sobczak, J. Mater. Eng. Perform. 29, 4898–4912 (2020)

M. Li, X. Song, S. Hu, Z. Chen, Y. Song, C. Niu, J. Am. Ceram. Soc. 102, 3318–3328 (2019)

Z. Li, R. Wei, Q. Wen, Z. Zhong, K. Song, Y. Wu, Vacuum 173, 109160 (2020)

B. Wu, X. Leng, Z. Xiu, J. Yan, Sci. Rep. (2018). https://doi.org/10.1038/s41598-018-34635-w

W. Yu, Y. Liu, X. Liu, Mater. Des. 150, 9–16 (2018)

L.C. Tsao, S.Y. Chang, Y.C. Yu, Trans. Nonferr. Metal. Soc. 28, 748–756 (2018)

S. Mishra, A. Sharma, D.H. Jung, J.P. Jung, Met. Mater. Int. 26, 1087–1098 (2020)

Y.S. Chung, T. Iseki, Eng. Fract. Mech. 40, 941–949 (1991)

L. Gremillard, E. Saiz, V.R. Radmilovic, A.P. Tomsia, J. Mater. Res. 21, 3222–3233 (2006)

C. Rado, S. Kalogeropoulou, N. Eustathopoulos, Mater. Sci. Eng. A 276, 195–202 (2000)

L.X. Cheng, G.Y. Li, Z.L. Li, Z.Z. Wu, B. Zhou, J. Mater. Sci. Mater. Electron. 26, 6004–6012 (2015)

A.K. Niessen, F.R. de Boer, R. Boom, P.F. de Chatel, Calphad 7, 51–70 (1983)

H. Yang, Doctoral Dissertation of Xiangtan University (2010)

W. Sutherland, IDEA Fit. J. 9, 781–785 (1905)

Z.X. Yang, H.R. Geng, Z.D. Tao, C.J. Sun, J. Atomic Mol. Phys. 21, 663–666 (2004)

L. Yuan, S. Ai-Hong, C. Guo-Yu, G. Bing-Dong, Acta Phys. Sin. 68, 268–275 (2019)

Y. Li, Master’s Dissertation of Jiangsu University (2017)

Q.L. Zhang, Inorganic Chemistry Series vol. 8, Titanium, vanadium, Chromium Group, 1st edn. (Science Press, Beijing, 1998)

J.G. Li, Mater. Lett. 22, 169–174 (1995)

J.G. Li, Mater. Chem. Phys. 47, 126–145 (1997)

B.W. Zhang, W.Y. Hu, X.L. Shu, Theory of Embedded Atom Method and its Application to Materials Science, 1st edn. (Hunan University Press, Changsha, 2003)

L.X. Cheng, M.R. Liu, X.Q. Wang, B.H. Yan, G.Y. Li, Mater. Sci. Eng. A 680, 317–323 (2017)

J. Li, L. Liu, Y. Wu, W. Zhang, W. Hu, Mater. Lett. 62, 3135–3138 (2008)

Acknowledgements

This work was supported by the National Natural Science Foundation of China [Grant No. 61804057] and the Science and Technology Planning Project of Guangdong [Grant No. 201803020022].

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation, data collection, and analysis were performed by LXC, KBM, XJY, and ZLL. The first draft of the manuscript was written by LXC and GYL, and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

No conflict of interest exits in the submission of this manuscript, and manuscript is approved by all authors and the responsible authorities at the institute for publication.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Cheng, L.X., Ma, K.B., Yue, X.J. et al. Role of Ti in direct active bonding of SiC substrate using Sn–Ag–Ti alloy filler. J Mater Sci: Mater Electron 33, 3331–3347 (2022). https://doi.org/10.1007/s10854-021-07533-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-021-07533-7