Abstract

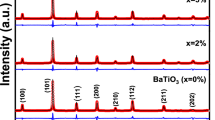

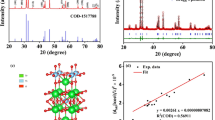

forsterite (Mg2SiO4) ceramic is an important millimeterwave dielectric ceramic with the advantages of low dielectric constant, high quality factor, and rich source of raw materials. forsterite ceramics were prepared by solid-state sintering. The effects of Mg/Si ratio (2–2.07) and sintering regime on the phase composition, microstructure, and dielectric properties of forsterite ceramics were investigated by X-ray diffraction, scanning electron microscopy, low-field nuclear magnetic resonance, and microwave network analyzer. The results show that excessive magnesium oxide can accelerate the solid-state reaction of magnesium oxide and silicon dioxide, limit the formation of enstatite (MgSiO3), and refine the grain size and pore structure, but excessive magnesium oxide makes forsterite ceramics difficult to densify and the total porosity of forsterite ceramics increases obviously. For the samples calcined at 1250 °C and sintered at 1250–1450 °C, with the increase of sintering temperature, the grain size of forsterite increases and the porosity of ceramics decreases; however, after it reaches 1425 °C, some grain boundaries begin to melt into glass phase and cracks or pores appear at some grains. Excessive magnesium oxide has little effect on the dielectric constant of forsterite ceramics, but increases the dielectric loss and reduces the quality factor.

Similar content being viewed by others

Data availability

The data used to support the findings of this study are available from the corresponding author upon reasonable request.

References

H. Ohsato, T. Tsunooka, T. Sugiyama, T. Sugiyama, K. Kakimoto, H. Ogawa, J. Electroceram. 17, 445–450 (2006)

T. Sugiyama, T. Tsunooka, K. Kakimoto, H. Ohsato, J. Eur. Ceram. Soc. 26, 2097–2100 (2006)

A. Ullah, H.X. Liu, P.C. Zhai, H. Hao, J. Iqbal, M.H. Cao, Z.H. Yao, A.S. Ahmad, A. Manan, J. Mater. Sci: Mater. Electron 30, 6469–6474 (2019)

G.Q. Zhang, H. Wang, J. Chin. Ceram. Soc. 45, 1256–1263 (2017)

A. Kazakos, S. Komarneni, R. Roy, Mater. Lett. 9(10), 405–409 (1990)

C. M. Shaw, University of California (1956)

G.W. Brindley, R. Hayami, Philos. Mag. 12(117), 505–514 (1965)

R.D. McDonnell, C.J. Spiers, C.J. Peach, Phys. Chem. Miner. 29(1), 19–31 (2002)

K.X. Song, X.M. Chen, X.C. Fan, J. Am. Ceram. Soc. 90(6), 1808–1811 (2007)

J. Li, Shaanxi Normal University (2016)

W. Liu, L. Xing, et al., Nuclear magnetic resonance logging.1st edn. (Petroleum Industry, Beijing, 2007), pp.18–20

X.N. Li, Y.Q. Li, C. Chen, D.W. Zhao, X.J. Wang, L. Zhao, H. Shi, G.H. Ma, Z.G. Su, J Porous Mater 22, 11–20 (2015)

S.Q. Yu, University of Electronic Science and Technology of China (2013)

H.M. Jiang, S.R. Zhang, X.H. Zhou, Piezoelectrics Acoustooptics 30(5), 615–617 (2008)

S.J. Penn, N.M. Alford, A. Templeton et al., J. Am. Ceram. Soc. 80(7), 1885–1888 (1997)

R. Heidinger, S. Nazare, Powder Metall. Inr. 20, 30–32 (1988)

M.T. Sebastian, H. Jantunen, R. Ubic, Microwave materials and applications (John Wiley & Sons, Chichester, 2017), pp. 1–200

Y.M. Lai, X. Tang, H.W. Zhang, X.F. Liang, X. Huang, Y.X. Li, H. Su, Mater Res Bull 99, 496–502 (2018)

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

He, G., Li, Z., Dong, Y. et al. Effects of excessive magnesium oxide and sintering regime on microstructure and dielectric properties of forsterite ceramics for millimeterwave dielectrics. J Mater Sci: Mater Electron 33, 3129–3138 (2022). https://doi.org/10.1007/s10854-021-07515-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-021-07515-9