Abstract

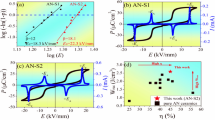

Dielectric capacitors have attracted extensive attention due to their high power density along with fast charge/discharge rate. Despite the high energy storage performance were obtained in lead-based ceramics, we still need to find lead-free ceramic alternatives considering the environmental requirements, and AgNbO3 has received extensive attention owing to its ferroelectric–antiferroelectric (FE–AFE) phase transition. In our study, the AFE properties of the samples were improved by tuning the grain size and polarizability of ions, and excellent energy storage performance was obtained in Bi/Ta co-doped AgNbO3. The BANT ceramic exhibited a remarkably enhanced recoverable energy density of 3.9 J/cm3 and acceptable efficiency of 61%. Morphological and structural analyses and electrical properties revealed that this co-substitution can optimize the AFE properties of the material, which can be demonstrated by the slim P–E loops and the reduced grain sizes. Of note, the BANT6 ceramic exhibited fast discharge speed accompanied by the actual energy storage density of up to 3.5 J/cm3 under 260 kV/cm. These findings indicate that AgNbO3-based AFE ceramics are a prospective alternative for energy storage materials applied to high-pulse-power fields.

Similar content being viewed by others

Data availability

The data that support the findings of this study are available from School of Materials, Guilin University of Electronic Science and Technology, but restrictions apply to the availability of these data, which were used under license for the current study, and so are not publicly available. Data are, however, available from the authors upon reasonable request and with permission of Pro. Changlai Yuan.

References

P. Redhu, A. Hooda, P. Sharma, S. Dahiya, R. Punia, R.P. Tandon, Ferroelectrics 569, 136 (2020). https://doi.org/10.1080/00150193.2020.1791661

K.M. Slenes, P. Winsor, T. Scholz, M. Hudis, IEEE Trans. Magn. 37, 324 (2001). https://doi.org/10.1109/20.911847

J. Cherusseri, N. Choudhary, K.S. Kumar, Y. Jung, J. Thomas, Nanoscale Horiz. 4, 840 (2019). https://doi.org/10.1039/c9nh00152b

M. Zhou, R. Liang, Z. Zhou, S. Yan, X. Dong, ACS Sustain. Chem. Eng. 6, 12755 (2018). https://doi.org/10.1021/acssuschemeng.8b01926

Y. Ahn, J. Seo, J.Y. Son, Appl. Surf. Sci. 357, 429 (2015). https://doi.org/10.1016/j.apsusc.2015.09.037

Z.S. Wu, K. Parvez, X. Feng, K. Mullen, Nat. Commun. 4, 2487 (2013). https://doi.org/10.1038/ncomms3487

X. Wei, H. Yan, T. Wang et al., J. Appl. Phys. (2013). https://doi.org/10.1063/1.4775493

H. Wang, P. Zhao, L. Chen, L. Li, X. Wang, J. Adv. Ceram. 9, 292 (2020). https://doi.org/10.1007/s40145-020-0367-8

Z.M. Dang, J.K. Yuan, S.H. Yao, R.J. Liao, Adv. Mater. 25, 6334 (2013). https://doi.org/10.1002/adma.201301752

A. Chelkowski, Dielectric Physics (Elsevier, New York, 1980)

C. Kittel, Phys. Rev. 82, 729 (1951). https://doi.org/10.1103/PhysRev.82.729

Z. Liu, X. Chen, W. Peng et al., Appl. Phys. Lett. (2015). https://doi.org/10.1063/1.4923373

X. Hao, J. Zhai, X. Yao, J. Am. Ceram. Soc. 92, 1133 (2009). https://doi.org/10.1111/j.1551-2916.2009.03015.x

D. Fu, M. Endo, H. Taniguchi, T. Taniyama, M. Itoh, Appl. Phys. Lett. (2007). https://doi.org/10.1063/1.2751136

A. Ratuszna, J. Pawluk, A. Kania, Phase. Transit. 76, 611 (2003). https://doi.org/10.1080/0141159021000009007

P. Sciau, A. Kania, B. Dkhil, E. Suard, A. Ratuszna, J. Phys. 16, 2795 (2004). https://doi.org/10.1088/0953-8984/16/16/004

I. Levin, V. Krayzman, J.C. Woicik et al., Phys. Rev. B (2009). https://doi.org/10.1103/PhysRevB.79.104113

A. Kania, Ferroelectrics 205, 19 (2011). https://doi.org/10.1080/00150199808228384

A. Kania, A. Niewiadomski, S. Miga et al., J. Eur. Ceram. Soc. 34, 1761 (2014). https://doi.org/10.1016/j.jeurceramsoc.2014.01.016

L. Zhao, Q. Liu, J. Gao, S. Zhang, J.F. Li, Adv. Mater. (2017). https://doi.org/10.1002/adma.201701824

N.N. Luo, K. Han, F.P. Zhuo et al., J. Mater. Chem. A 7, 14118 (2019). https://doi.org/10.1039/c9ta02053e

Y. Tian, L. Jin, H. Zhang et al., J. Mater. Chem. A 5, 17525 (2017). https://doi.org/10.1039/c7ta03821f

U. Bharagav, N.R. Reddy, K. Pratap et al., in Photocatalytic Systems by Design. ed. by M. Sakar, R.G. Balakrishna, T.-O. Do (Elsevier, New York, 2021)

I.O. Alade, Y. Zhang, X. Xu, N. J. Chem. 45, 15255 (2021). https://doi.org/10.1039/d1nj01523k

H. Wei, C. Yang, Y. Wu, B. Cao, M. Lorenz, M. Grundmann, J. Mater. Chem. C 8, 15575 (2020). https://doi.org/10.1039/d0tc02811h

J. Fabry, Z. Zikmund, A. Kania, V.V. Petricek, Acta Crystallogr. C 56(8), 916 (2000). https://doi.org/10.1107/s0108270100006806

Y. Zhang, X. Xu, J. Magn. Magn. Mater. (2020). https://doi.org/10.1016/j.jmmm.2020.166998

F. Zhuo, H. Qiao, J. Zhu et al., Chin. Chem. Lett. 32, 2097 (2021). https://doi.org/10.1016/j.cclet.2020.11.070

Y. Zhang, X. Xu, AIP Adv. (2001). https://doi.org/10.1063/1.5144241

A. Kania, J. Phys. D 34, 1447 (2001). https://doi.org/10.1088/0022-3727/34/10/302

M.H. Francombe, B. Lewis, Acta. Crystallogr. 11, 175 (1958). https://doi.org/10.1107/s0365110x58000463

M. Łukaszewski, M. Pawełczyk, J. Haňderek, A. Kania, Phase. Transit. 3, 247 (2006). https://doi.org/10.1080/01411598308243024

L. Li, M. Spreitzer, D. Suvorov, Appl. Phys. Lett. (2014). https://doi.org/10.1063/1.4875581

L. Zhao, Q. Liu, S. Zhang, J.-F. Li, J. Mater. Chem. C 4, 8380 (2016). https://doi.org/10.1039/c6tc03289c

S. Li, T. Hu, H. Nie et al., Energy Storage Mater. 34, 417 (2021). https://doi.org/10.1016/j.ensm.2020.09.021

N. Luo, K. Han, M.J. Cabral et al., Nat. Commun. 11, 4824 (2020). https://doi.org/10.1038/s41467-020-18665-5

D. Yang, J. Gao, L. Shu et al., J. Mater. Chem. A 8, 23724 (2020). https://doi.org/10.1039/d0ta08345c

H. Chen, J. Shi, X. Chen et al., J. Mater. Chem. A 9, 4789 (2021). https://doi.org/10.1039/d0ta11022a

H. Qi, R. Zuo, A. Xie et al., Adv. Funct. Mater. (2019). https://doi.org/10.1002/adfm.201903877

J. Ye, G. Wang, M. Zhou et al., J. Mater. Chem. C 7, 5639 (2019). https://doi.org/10.1039/c9tc01414d

Z. Yang, H. Du, L. Jin et al., J. Mater. Chem. A 7, 27256 (2019). https://doi.org/10.1039/c9ta11314b

W.-B. Li, D. Zhou, L.-X. Pang, J. Mater. Sci. 28, 8749 (2017). https://doi.org/10.1007/s10854-017-6600-8

H. Yang, F. Yan, Y. Lin, T. Wang, ACS Sustain. Chem. Eng. 5, 10215 (2017). https://doi.org/10.1021/acssuschemeng.7b02203

X. Kong, L. Yang, Z. Cheng, S. Zhang, J. Am. Ceram. Soc. 103, 1722 (2019). https://doi.org/10.1111/jace.16844

J. Li, F. Li, Z. Xu, S. Zhang, Adv. Mater. (2018). https://doi.org/10.1002/adma.201802155

Y. Wu, Y. Fan, N. Liu et al., J. Mater. Chem. C 7, 6222 (2019). https://doi.org/10.1039/c9tc01239g

C. Cui, Y. Pu, J. Mater. Sci. 53, 9830 (2018). https://doi.org/10.1007/s10853-018-2282-8

C. Luo, Q. Feng, N. Luo et al., Chem. Eng. J. (2021). https://doi.org/10.1016/j.cej.2021.129861

Z. Chen, X. Bai, H. Wang et al., Ceram. Int. 46, 11549 (2020). https://doi.org/10.1016/j.ceramint.2020.01.181

H. Sun, X. Wang, Q. Sun et al., J. Eur. Ceram. Soc. 40, 2929 (2020). https://doi.org/10.1016/j.jeurceramsoc.2020.03.012

Z. Lu, W. Bao, G. Wang et al., Nano Energy (2021). https://doi.org/10.1016/j.nanoen.2020.105423

Y. Tian, L. Jin, Q. Hu et al., J. Mater. Chem. A 7, 834 (2019). https://doi.org/10.1039/c8ta10075f

W. Chao, T. Yang, Y. Li, Z. Liu, J. Am. Ceram. Soc. 103, 7283 (2020). https://doi.org/10.1111/jace.17415

J. Gao, Q. Liu, J. Dong, X. Wang, S. Zhang, J.F. Li, ACS Appl. Mater. Inter. 12, 6097 (2020). https://doi.org/10.1021/acsami.9b20803

F. Li, M. Zhou, J. Zhai, B. Shen, H. Zeng, J. Eur. Ceram. Soc. 38, 4646 (2018). https://doi.org/10.1016/j.jeurceramsoc.2018.06.038

C.W. Ahn, G. Amarsanaa, S.S. Won, S.A. Chae, D.S. Lee, I.W. Kim, ACS Appl. Mater. Inter. 7, 26381 (2015). https://doi.org/10.1021/acsami.5b08786

J. Shi, X. Chen, X. Li et al., J. Mater. Chem. C 8, 3784 (2020). https://doi.org/10.1039/c9tc06711f

N. Luo, K. Han, F. Zhuo et al., J. Mater. Chem. C 7, 4999 (2019). https://doi.org/10.1039/c8tc06549g

Z Liu, T Lu, J Ye, et al. (2018) Adv. Mater. Technol. https://doi.org/10.1002/admt.201800111

K. Han, N. Luo, S. Mao et al., J. Mater. Chem. A 7, 26293 (2019). https://doi.org/10.1039/c9ta06457e

M. Yashima, S. Matsuyama, R. Sano, M. Itoh, K. Tsuda, D. Fu, Chem. Mater. 23, 1643 (2011). https://doi.org/10.1021/cm103389q

H.U. Khan, K. Alam, M. Mateenullah, T. Blaschke, B.S. Haq, J. Eur. Ceram. Soc. 35, 2775 (2015). https://doi.org/10.1016/j.jeurceramsoc.2015.04.007

I. Levin, J.C. Woicik, A. Llobet et al., Chem. Mater. 22, 4987 (2010). https://doi.org/10.1021/cm101263p

S. Li, H. Nie, G. Wang et al., J. Mater. Chem. C 7, 1551 (2019). https://doi.org/10.1039/c8tc05458d

T. Tunkasiri, G. Rujijanagul, J. Mater. Sci. Lett. 15, 1767 (1996). https://doi.org/10.1007/bf00275336

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (Grant No. 11464006) and Guangxi Key Laboratory of Information Materials (Grant No. 191026–Z).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yang, D., Lan, Y., Yuan, C. et al. Enhanced energy storage density of antiferroelectric AgNbO3-based ceramics by Bi/Ta modification at A/B sites. J Mater Sci: Mater Electron 33, 3081–3090 (2022). https://doi.org/10.1007/s10854-021-07511-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-021-07511-z