Abstract

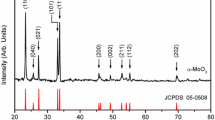

In this study, nanotubular structures were prepared on tantalum film via anodisation using an organic-based electrolyte. Nanotubular tantalum pentoxide (Ta2O5) was synthesised at 30 and 60 min and fabricated as a humidity sensor. The significant growth of anodised nanotubular Ta2O5 has increased the number of pore structures and offered more water absorption active sites for humidity sensing detection. Both anodised samples were annealed to transform an amorphous structure to a cubic crystal structure, where the presence of more crystalline peaks was justified by the XRD spectra. The formation of pore size was proven by FESEM images and the density of pore distribution of the 60-min sensor was higher than the 30-min sensor with a diameter of 10–50 nm and 15–20 nm, respectively. Both fabricated sensors were tested for humidity detection in the range of 40–90% humidity level. Based on the results obtained, the 60-min sensor operated at 10 V possessed the highest sensitivity, low hysteresis, and improved stability compared to the 30-min sensor operated at the same bias voltage. Thus, this paper has elucidated the relationship of anodising time during nanostructure construction towards the variation of current output in humidity sensing due to the availability of oxygen vacancies and active sites as an effort to improve humidity sensing.

Similar content being viewed by others

Data availability

The datasets generated during and/or analysed during the current study are available from the corresponding author on reasonable request.

Code availability

Not applicable.

References

G. Korotcenkov, B.K. Cho, Sens. Actuators B 244, 182 (2016). https://doi.org/10.1016/j.snb.2016.12.117

A. Dey, Mater. Sci. Eng. B 229, 206 (2018). https://doi.org/10.1016/j.mseb.2017.12.036

J.N. Hasnidawani, H.N. Azlina, H. Norita, N.N. Bonnia, Procedia Chem. 19, 211 (2016). https://doi.org/10.1016/j.proche.2016.03.095

Z. Zhang, Z. Wen, Z. Ye, L. Zhu, J. Alloys Compd. 727, 436 (2017). https://doi.org/10.1016/j.jallcom.2017.07.181

J. Huang, K. Zhang, Y. Lai, Handb. Nanoelectrochem. (2016). https://doi.org/10.1007/978-3-319-15266-0_17

M.M. Momeni, M. Mirhosseini, M. Chavoshi, Surf. Eng. 33, 83 (2015). https://doi.org/10.1179/1743294415Y.0000000071

R.V. Gonçalves, H. Wender, P. Migowski, A.F. Feil, D. Eberhardt, J. Boita, S. Khan, G. Machado, J. Dupont, S.R. Teixeira, J. Phys. Chem. 121, 5855 (2017). https://doi.org/10.1021/acs.jpcc.6b10540

A. Salamat, T. Islam, Instrum. Sci. Technol. 48, 128 (2020). https://doi.org/10.1080/10739149.2019.1662803

D. Nunes, A. Pimentel, A. Gonçalves, S. Pereira, R. Branquinho, P. Barquinha, E. Fortunato, R. Martins, Semicond. Sci. Technol. (2017). https://doi.org/10.1088/1361-6641/ab011e

S. Pratibha, B. Chethan, Y.T. Ravikiran, N. Dhananjaya, V.J. Angadi, Sens. Actuators A 304, 111903 (2020). https://doi.org/10.1016/j.sna.2020.111903

H. Ma, H. Fang, W. Wu, C. Zheng, L. Wu, H. Wang, R. Soc. Chem. 10, 25467 (2020). https://doi.org/10.1039/D0RA03958F

R.S. Khaleel, M.S. Hashim, Kuwait J. Sci. 47, 42 (2020)

C.K. Chung, O.K. Khor, E.H. Kuo, C.A. Ku, Mater. Lett. 260, 126921 (2020). https://doi.org/10.1016/j.matlet.2019.126921

D.L. Gapale, S.A. Arote, B.M. Palve, S.N. Dalvi, R.Y. Borse, Mater. Res. Express (2018). https://doi.org/10.1088/2053-1591/aae970

S. Singh, G. Gupta, S. Yadav, P.K. Dubey, Sens. Actuators A 295, 133 (2019). https://doi.org/10.1016/j.sna.2019.05.023

Y. Freeman, J.S. State, S. Technol, ECS J. Solid State Sci. Technol. (2017). https://doi.org/10.1149/2.0031708jss

N.L.S. Ngadiman, R.A. Rani, S.R. Makhsin, M.A. Ayub, N.H. Saad, M. Zolkipli, A.S. Zoolfakar, 2020 IEEE International Conference on Semiconductor Electronics. (2020). https://doi.org/10.1109/ICSE49846.2020.9166891

M.A. Abu Talip, N.S. Khairir, R.A. Kadir, M.H. Mamat, R.A. Rani, M.R. Mahmood, A.S. Zoolfakar, J. Mater. Sci.: Mater. Electron. 30, 4953 (2019). https://doi.org/10.1007/s10854-019-00792-5

H. Li, H. Guo, K. Huang, B. Liu, C. Zhang, X. Chen, X. Xu, J. Yang, Appl. Phys. A (2018). https://doi.org/10.1007/s00339-018-2182-4

C. Mayousse, C. Celle, A. Fraczkiewicz, J.-P. Simonato, Nanoscale (2014). https://doi.org/10.1039/C4NR06783E

R.A. Rani, A. Sabirin, M.F. Mohamad, A.S. Ismail, M.H. Mamat, J. Electron. Mater. 48, 3805 (2019). https://doi.org/10.1007/s11664-019-07126-5

L. Manjakkal, K. Cvejin, J. Kulawik, K. Zaraska, R.P. Socha, D. Szwagierczak, Anal. Chim. Acta J. 931, 47 (2016). https://doi.org/10.1016/j.aca.2016.05.012

M. Sarraf, B.A. Razak, A. Dabbagh, N.H. Abu, W.J. Basirun, E. Bin, J. Mech. Behav. Biomed. Mater. 66, 129 (2016). https://doi.org/10.1016/j.jmbbm.2016.11.012

W. Wei, J.M. Macak, P. Schmuki, Electrochem. Commun. 10, 428 (2008). https://doi.org/10.1016/j.elecom.2008.01.004

M.R. Nickel, G. Melligan, T.P.W. Mcmullen, R.E. Burrell, Thin Solid Films 685, 245 (2019). https://doi.org/10.1016/j.tsf.2019.06.033

S. Minagar, C. Berndt, C. Wen, J. Funct. Biomater. 6, 153 (2015). https://doi.org/10.3390/jfb6020153

R.S. Brown, Investigating the Properties and Application of Tantalum Pentoxide Nanostructures for Cancer Radiotherapy (University of Wollongong, Wollongong, 2017)

R. Nakamura, K. Asano, M. Ishimaru, K. Sato, M. Takahashi, H. Numakura, J. Mater. Res. 29, 753 (2014). https://doi.org/10.1557/jmr.2014.44

N.L.S. Ngadiman, R.A. Rani, Z.F. Zulkifli, M.F. Abdullah, S.R. Makhsin, M. Zolkapli, A.S. Zoolfakar, M. Nour, Proceedings—2021 IEEE Regional Symposium Micro Nanoelectronics RSM 2021. (2021) https://doi.org/10.1109/RSM52397.2021.9511581

D. Lan, X. Zhao, F. Wang, C. Ai, D. Wen, H. Zhang, Int. J. Mod. Phys. B 32, 1 (2018). https://doi.org/10.1142/S0217979218501990

Z. Chen, C. Lu, Sens. Lett. 3, 274 (2005). https://doi.org/10.1166/sl.2005.045

Y. Li, K. Nagato, J. Delaunay, J. Kubota, Nanotechnology (2014). https://doi.org/10.1088/0957-4484/25/1/014013

W. Chen, Q. Tu, H. Wu, C. Zhao, X. Yao, W. Fan, S. Zhang, J. Ni, X. Zhang, Electrochim. Acta 236, 140 (2017). https://doi.org/10.1016/j.electacta.2017.03.024

R.A. Rani, S. Zoolfakar, A.P.O. Mullane, M.W. Austin, K. Kalantar-zadeh, J. Mater. Chem. A 2, 15683 (2014). https://doi.org/10.1039/C4TA02561J

S. Maeng, L. Axe, T. Tyson, A. Jiang, J. Electrochem. Soc. (2005). https://doi.org/10.1149/1.1850362

S.W. Park, J.M. Choi, K.H. Lee, H.W. Yeom, S. Im, Y.K. Lee, J. Phys. Chem. B 114, 5661 (2010). https://doi.org/10.1021/jp910459p

R.P. Wang, S.J. Madden, C.J. Zha, A.V. Rode, B. Luther-Davies, J. Appl. Phys. 100, 1 (2006). https://doi.org/10.1063/1.2353787

A. Sharma, Y. Kumar, P.M. Shirage, J. Mater. Sci.: Mater. Electron. 29, 10769 (2018). https://doi.org/10.1007/s10854-018-9143-8

V. Uvarov, I. Popov, Mater. Charact. 85, 111–123 (2013). https://doi.org/10.1016/j.matchar.2013.09.002

W. Yue, W. Zhou, Prog. Nat. Sci. 18, 1329 (2008). https://doi.org/10.1016/j.pnsc.2008.05.010

W. Lisowski, G. Trykowski, Nanomaterials 9, 1347 (2019). https://doi.org/10.3390/nano9101347

R.V. Gonçalves, P. Migowski, H. Wender, A.F. Feil, M.J.M. Zapata, S. Khan, F. Bernardi, G.M. Azevedo, S.R. Teixeira, CrystEngComm 16, 797 (2014). https://doi.org/10.1039/c3ce42043d

W. Ren, G.D. Yang, A.L. Feng, R.X. Miao, J.B. Xia, Y.G. Wang, J. Adv. Ceram. 10, 704 (2021). https://doi.org/10.1007/s40145-021-0465-2

M.H. Feng, W.C. Wang, X.J. Li, J. Alloys Compd. 698, 94 (2017). https://doi.org/10.1016/j.jallcom.2016.11.370

H.A. Gatea, J. Mater. Sci.: Mater. Electron. 31, 22119 (2020). https://doi.org/10.1007/s10854-020-04714-8

D. Zhang, H. Chang, P. Li, R. Liu, Q. Xue, Sens. Actuators B 225, 233 (2016). https://doi.org/10.1016/j.snb.2015.11.024

S.C. Vijayakumari, C.H.V.V. Ramana, S. Thomas, D. Kim, Talanta 196, 337 (2018). https://doi.org/10.1016/j.talanta.2018.12.072

X. Cha, F. Yu, Y. Fan, J. Chen, L. Wang, Q. Xiang, Z. Duan, J. Xu, Sens. Actuators B 263, 436 (2018). https://doi.org/10.1016/j.snb.2018.01.110

K. Rathi, K. Pal, ACS Omega 2, 842 (2017). https://doi.org/10.1021/acsomega.6b00399

M.A. Mir, M.A. Shah, P.A. Ganai, J. Solid State Electrochem. 24, 1679 (2020). https://doi.org/10.1007/s10008-020-04683-2

J.J. Steele, M.T. Taschuk, M.J. Brett, IEEE Sens. J. 8, 1422 (2008). https://doi.org/10.1109/JSEN.2008.920715

Y. Zhang, K. Yu, D. Jiang, Z. Zhu, H. Geng, L. Luo, Appl. Surf. Sci. 242, 212 (2005). https://doi.org/10.1016/j.apsusc.2004.08.013

H. Farahani, R. Wagiran, M.N. Hamidon, Sensors 14, 7881 (2014). https://doi.org/10.3390/s140507881

B. Chethan, H.G.R. Prakash, Y.T. Ravikiran, S.C. Vijayakumari, S. Thomas, Sens. Actuators B 296, 126639 (2019). https://doi.org/10.1016/j.snb.2019.126639

Y. Zhang, H. Zou, J. Peng, Z. Duan, M. Ma, X. Xin, W. Li, X. Zheng, Sens. Actuators B 272, 459 (2018). https://doi.org/10.1016/j.snb.2018.06.007

Y. Gu, Z. Ye, N. Sun, X. Kuang, W. Liu, X. Song, L. Zhang, W. Bai, J. Mater. Sci.: Mater. Electron. (2019). https://doi.org/10.1007/s10854-019-02230-y

S. Manjunatha, T.M.Y.T. Ravikiran, B.C.M. Revanasiddappa, Appl. Phys. A 6, 104003 (2019). https://doi.org/10.1007/s00339-019-2638-1

K.Z. Soderznik, C. Fabrega, F. Hernandez-Ramirez, J.D. Prades, Č Miran, Proceedings 15, 7 (2019). https://doi.org/10.3390/proceedings2019015009

L.P.B. Reddy, H.G.R. Prakash, Y.T. Ravikiran, S.K. Ganiger, V.J. Angadi, J. Mater. Sci.: Mater. Electron. 31, 21981 (2020). https://doi.org/10.1007/s10854-020-04701-z

S.Y. Hussein, S.A. Kakil, T.A.H. Abbas, L.H. Slewa, J. Mater. Sci.: Mater. Electron. 31, 15466 (2020). https://doi.org/10.1007/s10854-020-04109-9

Funding

This work is supported by the Ministry of Education Malaysia (MOE) under the Fundamental Research Grant Scheme (FRGS) [Grant No. 600-IRMI/FRGS 5/3 (389/2019)].

Author information

Authors and Affiliations

Contributions

NLSN performed the experiments and analysed the data and wrote the manuscript. RAR helped to analyse the data, contributed to the final version of the manuscript, supervised the project, and is in charge of overall direction and planning. SRM and MAA helped to supervise the project. MAAT contributed to sample preparation. ASZ contributed to the design and implementation of the experiment.

Corresponding author

Ethics declarations

Conflict of interest

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ngadiman, N.L.S., Abdul Rani, R., Makhsin, S.R. et al. Facile fabrication method and decent humidity sensing of anodised nanotubular Ta2O5 on Ta foil substrate. J Mater Sci: Mater Electron 33, 3065–3080 (2022). https://doi.org/10.1007/s10854-021-07509-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-021-07509-7