Abstract

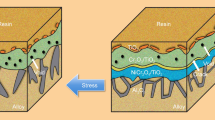

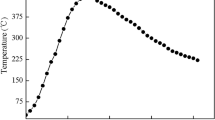

In this study, the effects of reflow temperature, reflow time, and substrates (polycrystalline and (001/110/111) monocrystalline Cu substrates) on the growth of Cu3Sn at the Cu/Sn3Ag interface were investigated. Results show that the growth of Cu3Sn on the interface shows grain boundary diffusion regardless of the orientation of Cu substrates. The formation of Cu3Sn is considered as the reaction between Cu atoms and Cu6Sn5 at Cu6Sn5/Cu3Sn interface due to the similar interfacial outline to Cu substrate. In addition, the growth of interfacial Cu3Sn is positively correlated with reflow temperature and time. And the preferred plane orientation of Cu substrate has a significant effect on the growth rate of Cu3Sn during reflowing. In this experiment, the growth of Cu3Sn shows grain boundary diffusion. The growth of Cu3Sn on polycrystalline Cu substrate is faster because it has a lot grain boundaries. And the growth rate on (110)Cu single crystals is the fastest among single-crystal Cu substrates because the high surface free energy of single-crystal oriented (110)Cu substrates promotes the growth of Cu3Sn and the diffusion distance of Cu atoms is the shortest in this direction.

Similar content being viewed by others

Data availability

The raw/processed data required to reproduce these findings cannot be shared at this time due to technical or time limitations.

References

K.N. Tu, Reliability challenges in 3D IC packaging technology. Microelectron. Reliab. 51, 517–523 (2011)

J.H. Lau, Overview and outlook of through-silicon via (TSV) and 3D integrations. Microelectron. Int. 28(2), 8–22 (2011)

Beyne E. 3D system integration technologies [C]. VLSI Technology, Systems, and Applications, 2006 International Symposium on, Taiwan, 2006:1-9

J.F. Li, P.A. Agyakwa, C.M. Johnson, Acta Mater. 59, 1198–1211 (2011)

N.S. Bosco, F.W. Zok, Acta Mater. 52, 2965–2972 (2004)

S. Sommadossi, L. Litynska, P. Zieba, W. Gust, E.J. Mittemeijer, Mater. Chem. Phys. 81, 566–568 (2003)

D. Q. Yu, C. K. Lee, L. L. Yan, W. K. Choi, A. Yu, J. H. Lau. Appl. Phys. Lett. 94 (2009) e034105.

R. Zhang, Y.H. Tian, C.J. Hang, B.L. Liu, C.Q. Wang, Mater. Lett. 110, 137–140 (2013)

Y. Wang, Y. Liu, M. Li, K. N. Tu, L. Xu. Interconnect quality and reliability of 3D packaging. Springer (2017).

S.F. Choudhury, L. Ladani, J. Electron. Mater. 43, 996–1004 (2014)

M.L. Huang, J.F. Zhao, Z.J. Zhang, N. Zhao, Acta Mater. 100, 98–106 (2015)

Z.H. Zhang, M.Y. Li, Z.Q. Liu, S.H. Yang, Acta Mater. 104, 1–8 (2016)

C.M. Gourlay, S.A. Belyakov, Z.L. Ma, J.W. Xian, JOM 67, 2383–2393 (2015)

W.H. Zhong, Y.C. Chan, M.O. Alam et al., Effect of multiple reflow processes on the reliability of ball grid array (BGA) solder joints. J. Alloys. Compd. 414, 123–130 (2006)

A.S.M.A. Haseeb, Y.M. Leong, M.M. Arafat, In-situ alloying of Sn-3.5Ag solder during reflow through Zn nanoparticle addition and its effects on interfacial intermetallic layers. Intermetallics 54, 86–94 (2014)

L. Ashley, H. M. Dalal, D. B. Nguyen, et al. Method of forming copper interconnections with enhanced electromigration resistance and reduced defect sensitivity. US, 2001.

Lead-free solders for ribbon interconnection of crystalline silicon PERC solar cells with infrared soldering[C]//AIP Conference Proceedings. AIP Publishing LLC AIP Publishing, 2019.

C. W. Lin, W. H. Lu, H. T. Kuo, et al. Package-on-package structure and method of forming same. 2016.

ONS. FOI request: package size reduction without proportionate price cuts that have been used in the calculation of the CPI over the last year.

R. Labie, P. Limaye, K. W. Lee, et al. Reliability testing of Cu-Sn intermetallic micro-bump interconnections for 3D-device stacking[C]//Electronic System-Integration Technology Conference (ESTC), 2010 3rd. IEEE, 2010.

Z. Rui, Y. Tian, C. Hang, et al. Formation mechanism and orientation of Cu3Sn grains in Cu–Sn intermetallic compound joints. Mater. Lett. 2013, 110(nov.1):137–140.

Z. Rui, Y. Tian, B. Liu, et al. Growth mechanism of Cu–Sn full IMC joints on polycrystalline and single crystal Cu substrate[C]//Electronic Packaging Technology (ICEPT), 2013 14th International Conference on. IEEE, 2013.

Y. Y. Qiao, N. Zhao, C. Y. Liu, et al. Dramatic morphological reservation of prism-type Cu6Sn5 formed on single crystal Cu substrates under temperature gradient. Mater. Today Commun. 2020, 23:100928.

Y. H. Tian, C. Q. Wang, L. N. Niu. Morphologies of Cu6Sn5 in Sn3.0Ag0.5Cu lead-free solder joints on single crystal Cu substrates. 2012.

H. Zou, Q. Zhu, Z. Zhang, Growth kinetics of intermetallic compounds and tensile properties of Sn-Ag-Cu/Ag single crystal joint. J. Alloy. Compd. 461, 410–417 (2008)

A Q Y, B F G, B Z G, et al. Interface dynamics in one-dimensional nanoscale Cu/Sn couples. Acta Mater. 2017, 125:136–144.

J. Gong, C. Liu, P.P. Conway et al., Evolution of Cu–Sn intermetallics between molten Sn–Ag–Cu solder and Cu substrate. Acta Mater. 56(16), 4291–4297 (2008)

H.K. Kim, K.N. Tu, Kinetic analysis of the soldering reaction between eutectic Sn–Pb alloy and Cu accompanied by ripening. Phys. Rev. B 53(23), 16027–16034 (1996)

R. L. Xu, Y. C. Liu, C. Wei, et al. Effects of Zn additions on the structure of the soldered Sn-3.5Ag and Cu interfaces. Solder. Surf. Mt. Technol. 2010, 22(2):13–20.

Park M. S., Gibbons S. L., R. Arróyave. Phase-field simulations of intermetallic compound growth in Cu/Sn/Cu sandwich structure under transient liquid phase bonding conditions. Acta Mater. 2012, 60(18):6278–6287.

J. Mackerle, Finite element analysis and simulation of adhesive bonding, soldering and brazing: a bibliography (1976–1996). Model. Simul. Mater. Sci. Eng. 5(2), 159 (1997)

M.S. Park, M.K. Stephenson, C. Shannon et al., Experimental and computational study of the morphological evolution of intermetallic compound layers at the Cu/Sn interface under isothermal soldering conditions. Acta Mater. 60, 5125–5134 (2012)

Y. Zhong, N. Zhao, C.Y. Liu, W. Dong, Y. Y. Qiao, Y. P. Wang. Appl. Phys. Lett. 111 (2017) e223502.

H.K. Kim, K.N. Tu, Phys. Rev. B 53(23), 16027 (1996)

P. J., Shang, et al. Growth mechanisms of Cu3Sn on polycrystalline and single crystalline Cu substrates. Acta Mater. 2009.

Effect of Cu preferential orientation on the microstructure and properties of anodized CuxO Films. Eur. J. Inorg. Chem. 2020, 2020(3).

Acknowledgements

This work was supported by the National Natural Science Foundation of china (Grant No. 51871040).

Funding

This study was funded by National Natural Science Foundation of China (51871040).

Author information

Authors and Affiliations

Contributions

MS: Data curation, Formal analysis, Methodology, and Writing—original draft. CD: Data curation, Test, and Methodology. HM: Writing—review and editing. YW: Writing—review and editing. HM: Funding acquisition and Writing—review and editing.

Corresponding authors

Ethics declarations

Conflict of interest

We have no conflicts of interest to declare.

Research date policy

The data that support the findings of this study are available from the corresponding author upon reasonable request.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Shang, M., Dong, C., Ma, H. et al. Growth mechanism and kinetics of Cu3Sn in the interfacial reaction between liquid Sn and diversely oriented Cu substrates. J Mater Sci: Mater Electron 33, 2957–2969 (2022). https://doi.org/10.1007/s10854-021-07494-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-021-07494-x