Abstract

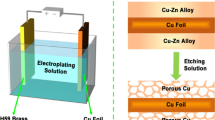

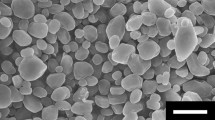

In this study, a two-step process involving oxygen plasma surface activation and thermos-compression in Pt-catalyzed formic acid gas was used to bond Cu foil and polyimide. The oxygen plasma was used to activate the polyimide surface to achieve strong adhesion with sputtered deposition film, and the Pt-catalyzed formic acid gas removed the oxides on the Cu surface effectively to promote bonding between Cu foil and polyimide. Via this method, a void-less bonding with a maximum shear strength of 20.31 MPa was achieved. The plasma bombardment was found to promote the formation of C-O-Cr and N-Cr bonds between polyimide and deposition metals, which improved their adhesion. After shear test, striped metal films remained on fracture surfaces at both polyimide and Cu foil sides, suggesting the fracture mainly occurred within adhered deposition metals rather than at bonding interface. This low-temperature bonding method is promising to achieve the direct integration between polyimide and copper foil without adhesive, which plays a key role in flexible device integration.

Similar content being viewed by others

References

Y. Khan, M. Garg, Q. Gui, M. Schadt, A. Gaikwad, D. Han, N.A.D. Yamamoto, P. Hart, R. Welte, W. Wilson, S. Czarnecki, M. Poliks, Z. Jin, K. Ghose, F. Egitto, J. Turner, A.C. Arias, Adv. Funct. Mater 26, 47 (2016)

K. Matsuura, J. Liang, K. Maezawa, N. Shigekawa, IEEE Trans. Electron Devices 66, 9 (2019)

T. Takano, H. Kudo, M. Tanaka, M. Akazawa, Y. Okazaki, H. Iida, K. Sakamoto, D. Kitayama, S. Yamada, S. Kuramochi, Int. Conf. Electron. Packag. Technol ICEPT 19, 2377 (2019)

R. Barrett, M. Faucon, J. Lopez, G. Cristobal, F. Destremaut, A. Dodge, P. Guillot, P. Laval, C. Masselon, J.-B. Salmon, Lab Chip 6, 494 (2006)

B. Weinhausen, S. Köster, Lab Chip 13, 212 (2013)

S.H. Kima, S.H. Choa, N.E. Leea, H.M. Kimb, Y.W. Namc, Y.H. Kimd, Surf Coat Technol 193, 101–106 (2005)

M.M.R. Howlader, T. Watanabe, T. Suga, J. Vac. Sci. Technol. B 19, 2114 (2001)

M.M.R. Howlader, T. Suga, A. Takahashi, J Mater Sci 40, 3177 (2005)

J. Liang, T. Miyazaki, M. Morimoto, S. Nishida, N. Watanabe, N. Shigekawa, Appl. Phys. Express 6, 021801 (2013)

A. Shigetou, T. Suga, Electronics Goes Green 2012, 1–6 (2012)

T. Suga, A. Takahashi, M. Howlader, K. Saijo and S. Oosawa (2002) IEEE Polytronic, 177–182

J. Liang, K. Furuna, M. Matsubara, M. Dhamrin, Y. Nishio, N. Shigekawa, ECS J. Solid State Sci. Technol. 6, 626 (2017)

Y. Nakamura, Y. Suzuki, Y, Watanabc, Thin Solid Flims 290, 367–369 (1996)

S. Park, H. Lee, J Colloid Interface Sci 285, 267–272 (2005)

T. Yang, D. Xie, Z. Li, H. Zhu, Mater. Sci. Eng., R 115, 1–37 (2017)

W. Yang, Y. Lu, S. Tadatomo, Int (Conf. Electron. Packag. Technol, ICEPT, 2016), pp. 784–787

M. Fujino, M. Akaike, N. Matsuoka, T. Suga, Jpn J Appl Phys 56, 0401 (2017)

Y.J. Kim, T.J. Byun, S.I. Kim, J.G. Han, J. Korean Phy. Soc. 53, 3 (2008)

S.B. Lee, Y.K. Kim, Plasma Process. Polym. 6, S525–S529 (2009)

R. He, M. Fujino, M. Akaike, T. Sakai, S. Sakuyama, T. Suga, Appl Surf Sci 414, 163–170 (2017)

A.M. Ektessabi, U.S. Hakamata, Thin Solid Films 377, 621 (2000)

K. Yamanaka, H. Yugawa, M. Harazono, Y. Hosoi, M. Fukui, N. Inagaki, IEEE Trans Compon Packaging Manuf Technol 1, 5 (2011)

Acknowledgements

This work was supported in part by National Natural Science Foundation of China under Grant Nos. 62004213, 61527816, 11634002, 61631021, 62074161, 61822407, and U20A20208; in part by the Key Research Program of Frontier Sciences, Chinese Academy of Sciences (CAS) under Grant No. QYZDB-SSW-JSC012; in part by the Youth Innovation Promotion Association of CAS; in part by the University of CAS; and in part by the Opening Project of Key Laboratory of Microelectronic Devices & Integrated Technology, Institute of Microelectronics, CAS.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Meng, Y., Xu, Y., Gao, R. et al. Low-temperature bonding of surface-activated polyimide to Cu Foil in Pt-catalyzed formic acid atmosphere. J Mater Sci: Mater Electron 33, 2582–2589 (2022). https://doi.org/10.1007/s10854-021-07463-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-021-07463-4