Abstract

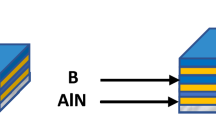

The demand for higher flux in light emitting diodes (LEDs) is associated with an increase in current density which impliedly leads to higher junction temperatures which affect the LEDs performance and operational life. It can be mitigated by minimizing the thermal path through the development and introduction of solid thermal interface material such as dielectric base. Consequently, the growth of AlNB composite based on varied Aluminium (Al) and Boron (B) thickness ratios (Al1−XNBX) for heat mitigation through heat spreading was performed using the reactive sputtering technique in N2:Ar gas ratios of 12:8 on Al substrates and annealed at 400 °C in N2 ambient. The surface microstructure and their variations are analyzed and observed the roughness in the range from 82 to 227 nm with an average particle size of ~ 200 nm. Surface cracks and thickness are measured from SEM analysis, while the structural characterization conducted by XRD confirmed the presence of Cubic aluminium nitride (c-AlN) (200 and 220), cubic boron nitride (c-BN) (111) and cubic aluminium (c-Al) (111 and 311) phases, respectively. The AlN and BN phases are also confirmed by FTIR spectra between ~ 545 and 1672 cm−1. Using the cumulative structure–function analysis, the noticeable reduction in total thermal resistance (Rthj-a) along the thermal path of the high power LED package is observed to be ~ 5.97 K/W compared with that of a bare aluminium substrate with 10.37 K/W. The lowest interfacial thermal resistance within the samples is found to be ~ 1.77 K/W and thus, the prepared AlNB composite highly recommended for effective heat spreading applications.

Similar content being viewed by others

References

LED Lighting Market Size, Share & Trends Analysis Report By End-use (Residential, Commercial), By Product (Lamps, Luminaires), By Application (Indoor, Outdoor), By Region, And Segment Forecasts, 2021–2028 (2021), https://www.grandviewresearch.com/industry-analysis/led-lighting-market. Accessed 20 July 2021

A.H. El-ladan, S. Subramani, Growth and performance analysis of BAlN alloy thin film on Al substrate as a heat spreader for effective thermal management applications on white-based high-power LED. Appl. Phys. A 127, 540 (2021). https://doi.org/10.1007/s00339-021-04617-3

A.H. El-ladan, S. Subramani, Development of AlNB alloy in (Al/AlN/B) stacking sequence using RF reactive sputtering towards thermal management application. J. Mater. Sci. Mater. Electron. 32, 577–589 (2021). https://doi.org/10.1007/s10854-020-04840-3

A.H. El-ladan, S. Subramani, synthesis and investigation of AlNB composite prepared by stacking methods for LED thermal management application ‘Unpublished Thesis Result’

G. Ke, Y. Tao, Y. Lu, Y. Bian, T. Zhu, H. Guo, Y. Chen, Highly c-axis oriented AlN film grown by unbalanced magnetron reactive sputtering and its electrical properties. J. Alloys Compd. 646, 446–453 (2015). https://doi.org/10.1016/j.jallcom.2015.05.174

B.D. Hahn, Y. Kim, C.W. Ahn, J.J. Choi, J. Ryu, J.W. Kim, W.H. Yoon, D.S. Park, S.Y. Yoon, B. Ma, Fabrication and characterization of aluminium nitride thick film coated on aluminium substrate for heat dissipation. Ceram. Int. 42, 18141–18147 (2016). https://doi.org/10.1016/j.ceramint.2016.08.128

A. Kumar, R.P. Yadav, V. Janyani, M. Prasad, Structural study of aluminium nitride thin film grown by radio frequency sputtering technique, in 2017 International Conference on Computer, Communications and Electronics (Comptelix). (IEEE, Jaipur, 2017), pp. 532–535. https://doi.org/10.1109/COMPTELIX.2017.8004027

Y. Lan, Y. Shi, K. Qi, Z. Ren, H. Liu, Fabrication and characterization of single-phase a-axis AlN ceramic films. Ceram. Int. 44, 8257–8262 (2018). https://doi.org/10.1016/j.ceramint.2018.02.007

K. Sato, H. Horibe, T. Shirai, Y. Hotta, H. Nakano, H. Nagai, K. Mitsuishid, K. Wataria, Thermally conductive composite films of hexagonal boron nitride and polyimide with affinity-enhanced interfaces. J. Mater. Chem. 20, 2749–2752 (2010). https://doi.org/10.1039/B924997D

K. Gordon, Thermal-management-of-white-leds.pdf US. DOE (2007), https://www1.eere.energy.gov/buildings/publications/pdfs/ssl/thermal_led_feb07_2.pdf, Accessed 28 June 2021

S. Subramani, M. Devarajan, Structural and surface analysis of chemical vapor deposited boron-doped aluminum nitride thin film on aluminum substrates. Mat. Sci.—Poland 37(3), 395–403 (2019). https://doi.org/10.2478/msp-2019-0056

M.S. Idris, S. Subramani, Performance of 9.0 W light-emitting diode on various layers of magnesium oxide thin film thermal interface materia. Appl. Phy. A. 126, 646 (2020). https://doi.org/10.1007/s00339-020-03820-y

M. Sundararajan, S. Subramani, M. Devarajan, M. Jaafar, Synthesis and analysis of anodic aluminum oxide-nanopore structure on Al substrates for efficient thermal management in electronic packaging. J. Mat. Sci. Mat. Electron. 31, 9641–9649 (2020). https://doi.org/10.1007/s10854-020-03507-3

N.J.A. Jamaludin, S. Subramani, Thermal performance of LED fixed on CVD processed ZnO thin film on Al substrates at various O2 gas flow rates. AIMS. Mat. Sci. 5(2), 246–256 (2018). https://doi.org/10.3934/matersci.2018.2.246

Z. Ong, S. Subramani, M. Devarajan, Thermal performance on born doped aluminium nitride thin film coated copper substrate of high power LED. J. Sci. Res. Rep. 5(2), 109–119 (2015). https://doi.org/10.9734/JSRR/2015/14232

Z. Habibaha, A.N. Arshad, L.N. Ismail, R.A. Bakar, M. Rusop, Chemical solution deposited magnesium oxide films: influence of deposition time on electrical and structural properties. Pro. Eng. 56, 737–742 (2013). https://doi.org/10.1016/j.proeng.2013.03.187

Lovkush, C. Ravikant, P. Arun, Plasmon coupling and aging effect in CsCl–Ag thin films. Mat. Res. Express 5(9), 6405 (2018). https://doi.org/10.1088/2053-1591/aad665

V.Y. Davydov, Y.E. Kitaev, I.N. Goncharuk et al., Phonon dispersion and Raman scattering in hexagonal GaN and AlN. Phys. Rev. B 58, 1289 (1988). https://doi.org/10.1103/PHYSREVB.58.12899

V.P. Filonenkoa, V.A. Davydova, I.P. Zibrovb, V.N. Agafonovc, V.N. Khabashesku, High pressure synthesis of new heterodiamond phase. Diam & Rel Mat 19, 541–544 (2010). https://doi.org/10.1016/j.diamond.2009.12.010

B. Singh, G. Kaur, P. Singh, K. Singh, B. Kumar, A. Vij, M. Kumar, R. Bala, R. Meena, A. Singh, A. Thakur, A. Kumar, Nanostructured boron nitride with high water dispersibility for boron neutron capture therapy. Sci. Rep. 6(1), 1–10 (2016). https://doi.org/10.1038/srep35535

J. Ying, X.W. Zhang, Z.G. Yin, H.R. Tan, S.G. Zhang, Y.M. Fan, Electrical transport properties of the Si-doped cubic boron nitride thin films prepared by in situ cosputtering. J. Appl. Phys. 109, 023716 (2011). https://doi.org/10.1063/1.3544065

Z. Yongnian, Z. Bing, H. Zhi, T. Yanchun, Z. Guangtian, Infrared spectroscopy investigation of cubic boron nitride films. Spect. Lett. 31(5), 945–954 (1998). https://doi.org/10.1080/00387019808003273

V. von, S¨. Eyhusen and Karlsruhe, Phase formation processes in the synthesis of boron nitride thin films, Dissertation zur Erlangung des Doktorgrades der Mathematisch-Naturwissenschaftlichen Fakult¨aten der Georg-August-Universit¨at zu G¨ottingen (2005)

Khavryuchenko, V. Oleksiy, S.A. Alekseev, A.S. Beobide, G. Kandilioti, G.A. Voyiatzis, V.V. Lisnyak, Combined vibrational spectroscopic and theoretical study on nature of c-BN powders surface. J. Phys. Chem. C 114(2), 1102–1109 (2010). https://doi.org/10.1021/JP908711X

X. Pian, G. Shao, B. Fan, H. Chen, C. Wang, R. Zhang, Rapid densification of SiC ceramic rollers by microwave sintering. Adv. Appl. Ceram. 114(1), 28–32 (2015). https://doi.org/10.1179/1743676114Y.0000000181

W. Hana, M. Chena, W. Songa, C. Gea, X. Zhanga, Construction of hexagonal boron nitride@polystyrene nanocomposite with high thermal conductivity for thermal management application. Ceram. Int. 46(6), 7595–7601 (2020). https://doi.org/10.1016/j.ceramint.2019.11.259

X. Li, S. Sundaram, Y. El Gmili, T. Moudakir, F. Genty, S. Bouchoule, G. Patriarche, R.D. Dupuis, P.L. Voss, J. Salvestrini, A. Ougazzaden, BAlN thin layers for deep UV applications. Phys. Stat. Solidi A 212(4), 745–750 (2015). https://doi.org/10.1002/pssa.201400199

M. Imura, Y. Ota, R.G. Banal, M. Liao, Y. Nakayama, M. Takeguchi, Y. Koide, Effect of boron incorporation on structural and optical properties of AlN layers grown by metal-organic vapor phase epitaxy. Phy. Stat. Solidi 215, 21 (2018). https://doi.org/10.1002/pssa.201800282

Understanding the difference between thermal impedance and thermal conductivity (2020), https://www.thermalspray.com/understanding-the-difference-between-thermal-impedance-and-thermal-conductivity/. Accessed 29 Apr 2020

K.P. Bhuvana, J. Elanchezhiyan, N. Gopalakrishnan, T. Balasubramanian, Influence of grain size on the properties of AlN doped ZnO thin film. Mat. Sci. Sem. Process. 14, 84–88 (2011). https://doi.org/10.1016/j.mssp.2011.01.005

Introduction to Roughness (2010), https://www.keyence.com/ss/products/microscope/roughness/line/. Accessed 20 July 2021

Acknowledgements

The first author would like to acknowledge Umaru Musa Yardua University, Katsina State and the TetFund Nigeria for research scholarship.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all the authors and the research institutions, there are not any conflict of interest financially, non-financially, directly, or indirectly related to the research work, the authors or between the authors and their research institution.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

El-ladan, A.H., Subramani, S. Influence of composition ratio on the thermal performance of AlNB nanocomposite for an efficient heat spreading in solid-state lighting package (LED). J Mater Sci: Mater Electron 33, 2183–2191 (2022). https://doi.org/10.1007/s10854-021-07425-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-021-07425-w