Abstract

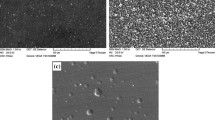

Electroless ZnO-reinforced Ni–P coatings are developed on mild steel substrates in the Electroless bath, which contains an optimum concentration of ZnO nanoparticles. This work focuses on the characteristics and properties of the Ni–P–ZnO coatings developed at different concentrations of reducing agent (sodium hypophosphite). Results confirm that the reducing agent greatly influences the deposition rate, surface roughness, hardness, and corrosion resistance of the coating. Reducing agent concentration influences the phosphorus present in the coating. An increase in the amorphous nature of the coating with an increase in reducing agent concentration improves the resistance to corrosion of the coating, but at the same time, it decreases the microhardness of the coating. High phosphorus deposition at the maximum amount of reducing agent concentration lowers the microhardness of the coating. The Hard Ni3P crystalline phase formed at 400 °C enhances the resistance to corrosion and microhardness of the coating. Scanning electron microscopy and X-ray diffraction studies are used to characterize the Ni–P–ZnO coating. The microhardness and corrosion resistance of the coating were evaluated using a Vickers microhardness tester and potentiodynamic polarization studies.

Similar content being viewed by others

References

A.R. Rahimi, H. Modarres, M. Abdouss, Surf. Eng. 25, 367 (2013)

S. Kundu, S.K. Das, P. Sahoo, Mater. Sci. Eng. Proc. 149, 1 (2016)

S. Sharma, A. Sharma, J. Mater. Eng. Perform. 25, 4383 (2016)

S. Karthikeyan, L. Vijayaraghavan, Trans. IMF 94, 265 (2016)

C. Vinod Babu, K. Ramji, M.V.A.R. Bahubalendruni, J. BioTriboCorros. 7, 1 (2021)

K.G. Keong, W. Sha, S. Malinov, Surf. Coating Technol. 168, 263 (2003)

J.N. Balaraju, S.K. Seshadri, Met. Fin. 97, 8 (1999)

S. Mauro, Dario, Mater. Technol. 51, 413 (2017)

H.A. Sorkhabi, S.H. Rafizadeh, Surf. Coatings Technol. 176, 318 (2004)

B.S. Choudhury, R.S. Sen, B. Oraon, G. Majumdar, Surf. Eng. 25, 410 (2009)

M. Yan, H.G. Ying, T.Y. Ma, Surf. Coating Technol. 202, 5909 (2008)

L. Gil, L. Jimenez, A.C. Castro, E.S. Puchi-Cabrera, M.H. Staia, Rev. de Metal 44, 66 (2008)

X.W. Li, Z.L. Chen, H.B. Hou, L. Hao, Corros. Eng. Sci. Technol. 45, 277 (2013)

G.G. Zusmanovich, Mater. Sci. Heat Treat. Metals 2, 229 (1960)

F.S. Goettems, J.Z. Ferreira, Mater. Res. 20, 1300 (2017)

J.N. Balaraju, S.K. Seshadri, Trans. IMF 77, 84 (1999)

Z.A. Hamid, M.T.A. Elkhair, Mater. Lett. 57, 720 (2002)

S.A. Gawad, A.M. Baraka, M.S. Morsi, Int. J. Electrochem. Sci. 8, 1722 (2013)

A. Farzaneh, M. Mohammadi, M. Ehteshamzadeha, F. Mohammadi, Appl. Surf. Sci. 276, 697 (2013)

S. Karthikeyan, B. Ramamoorthy, Appl. Surf. Sci. 307, 654 (2014)

P. Gadhari, P. Sahoo, Proced. Mater. Sci. 6, 623 (2014)

J.N. Balaraju, K.S. Rajam, Int. J. Electrochem. Sci. 2, 747 (2007)

D. Dong, X.H. Chen, W.T. Xiao, G.B. Yang, P.Y. Zhang, Appl. Surf. Sci. 255, 7051 (2009)

X.H. Chen, C.S. Chen, H.N. Xiao, H.B. Liu, L.P. Zhou, S.L. Li, G. Zhang, Tribol. Int. 39, 22 (2006)

M. Islam, M.R. Azhar, N. Fredj, M. Aleman, O.R. Oloyede, A.A. Almajid, S.I. Shah, Surf. Coating Technol. 261, 141 (2015)

J.N. Balaraju, V. Ezhil Selvi, K.S. Rajam, Mater. Chem. Phys. 120, 546 (2010)

S.A. Gawad, A.M. Baraka, M.S. Morsi, M.S.A. Eltoum, Int. J. Electrochem. Sci. 8, 1722 (2013)

J.N. Balaraju, T.S.N.S. Narayanan, S.K. Seshadri, J. Solid State Electrochem. 5, 334 (2001)

G.Y. Zou, H. Zhang, Z. Zou, Arch. Metall. Mater. 60, 865 (2015)

C. Vinod Babu, Mater. Res. Express 6, 025030 (2018)

Z. Yang, H. Xu, M. Li, Y. Shi, Y. Huang, H. Li, Thin Solid Films 466, 86 (2004)

M. Franco, W. Sha, S. Malinov, Surf. Coatings Technol. 235, 755 (2013)

C.Vinod Babu, K. Ramji, Mater. Res. Innov. 24, 67 (2020)

R. Hu, Y. Su, Y. Liu, H. Liu, Y. Chen, C. Cao, H. Ni, Nanoscale Res. Lett. 198, 1 (2018)

J.N. Balaraju, K.S. Rajam, Surf. Coatings Technol. 195, 154 (2005)

C. Vinod Babu, K. Ramji, J. BioTriboCorros. 4, 1 (2018)

S. Ranganatha, T.V. Venkatesha, K. Vathsala, Appl. Surf. Sci. 256, 7377 (2010)

L.G. Jiaqiang, L. Lei, S. Wu. Yating, W. Bin, W. Hu, Surf. Coating Technol. 200, 5836 (2005)

C. Vinod Babu, U. Sudhakar, R.C. Sharma, J. Critical Rev. 7, 268 (2020)

C. Vinod Babu, K. Ramji, G. Thirumala Rao, Adv. Mater. Proc. Technol. XX, 1 (2020)

Acknowledgements

One of the authors, Vinod Babu Chintada and Thirumala Rao Gurugubelli, wishes to express their gratitude to the GMRIT management for providing financial assistance through the SEED grant for the research.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors have no conflict of interest to declare that are relevant to the content of this article.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Chintada, V.B., Gurugubelli, T.R. & Koutavarapu, R. An investigation over the effect of the reducing agent on the properties of the ZnO-reinforced Ni–P coatings. J Mater Sci: Mater Electron 33, 950–958 (2022). https://doi.org/10.1007/s10854-021-07366-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-021-07366-4