Abstract

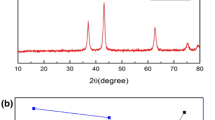

In this present work, the pristine and the different percentages of co-doped NiO nanoparticles have been successfully synthesized through the sol–gel method. The X-ray diffraction (XRD), Scanning Electron Microscopy (SEM), UV–Visible spectroscopy (UV-Vis), Fourier Transform Infra-Red Spectroscopy (FT-IR), and Vibrating Sample Magnetometer (VSM) were used to study the structural, morphological, optical, functional, and magnetic properties of the synthesized materials. The XRD patterns confirmed the formation of cubic phased NiO with their crystallite size, microstrain, dislocation density was estimated, and the average crystallite size increased with co-dopant inclusion. By introducing the co-dopant proportion in NiO lattice, the intensity of optical absorption was found to increase and the optical bandgap decreased from (Eg = 3.6, 3.54, 3.50 eV) due to quantum size effect. SEM result exhibits that the particles are spherical-shaped morphology. The VSM examination shows the magnetic transition of soft to hard-ferromagnetism in room temperature on Zn, Mn co-dopant ions occupying Ni translational symmetry.

Similar content being viewed by others

Data availability

Not applicable.

Code availability

Not applicable.

References

A. Neubecker, T. Pompl, T. Doll, W. Hansch, I. Eisele, Thin Solid Films 310, 19 (1997). https://doi.org/10.1016/S0040-6090(97)00329-5

G.M. Whitesides, Small 1, 172 (2005). https://doi.org/10.1002/smll.200400130

I. Yuko, W. Naoto, Y. Junichiro, Y. Saori, K. Yoshihide, K. Eriko, T. Hiroyuki, Phys. B 329, 862 (2003). https://doi.org/10.1016/S0921-4526(02)02578-4

L. Schmidt-Mende, J.L. MacManus-Driscoll, Mater. Today. 10, 40 (2007). https://doi.org/10.1016/S1369-7021(07)70078-0

R. Deng, B. Yao, Y.F. Li, Y. Xu, J.C. Li, B.H. Li, J. Lumin. 134, 240 (2013). https://doi.org/10.1016/j.jlumin.2012.08.039

Q.A. Pankhurst, J. Connolly, S. Jones, J. Dobson, J Phys D 36, R167 (2003). https://doi.org/10.1088/0022-3727/36/13/201

S. Farhadi, Z. Roostaei-Zaniyani, Polyhedron 30, 971 (2011). https://doi.org/10.1016/j.poly.2010.12.044

S.F. Wang, L.Y. Shi, X. Feng, S.R. Ma, Mater Lett. 67, 1549 (2007). https://doi.org/10.1016/j.matlet.2006.07.076

A. Santhoshkumar, H.P. Kavitha, R. Suresh, J. Adv. Chem. Sci. 2, 230 (2016)

W. Li, P. Haldar, Electrochem Solid State Lett. 13, B47 (2010). https://doi.org/10.1149/1.3313347

Z. Parsaee, Ultrason Sonochem. 44, 120 (2018). https://doi.org/10.1016/j.ultsonch.2018.02.021

N.N.M. Zorkipli, N.H.M. Kaus, A.A. Mohamad, Procedia Chem. 19, 626 (2016). https://doi.org/10.1016/j.proche.2016.03.062

L.G. Teoh, K.D. Li, Mater Trans. 53, 2135 (2012). https://doi.org/10.2320/matertrans.M2012244

M. Qamara, M.A. Gondal, Z.H. Yamania, J Mol Catal A 341, 83 (2011)

T.L. Lai, Y.Y. Shu, G.L. Huang, C.C. Lee, C.B. Wang, J Alloys Compd. 450, 318 (2008). https://doi.org/10.1016/j.jallcom.2006.10.114

P.V. Kumar, A.J. Ahamed, M. Karthikeyan, SN Appl. Sci. (2019). https://doi.org/10.1007/s42452-019-1113-0

I.S. Grace, J. Vinola, S. Deepapriya, D.R. John, A. Aslinjensipriya, R.S. Reena, A. Chamundeeswari, M. Jose, D.S. Jerome, AIP Conf. Proc. (2020). https://doi.org/10.1063/5.0009740

J. Al-Boukhari, L. Zeidan, A. Khalaf, R. Awad, Chem. Phys. 516, 116 (2018). https://doi.org/10.1016/j.chemphys.2018.07.046

A. Nakrela, N. Benramdane, A. Bouzidi, A. Kebba, M. Medles, C. Mathieu, Results Phys. 6, 133 (2016). https://doi.org/10.1016/j.rinp.2016.01.010

K. Anandan, V. Rajendran, MSEB. 199, 48 (2015). https://doi.org/10.1016/j.mseb.2015.04.015

S. Sankar, S.K. Sharma, N. An, H. Lee, D.Y. Kim, Y.B. Im, Y.D. Cho, R. Sankar, G.S. Ponnusamy, L.P. Raji, L.P. Purohit, Optik 127, 10727 (2016). https://doi.org/10.1016/j.ijleo.2016.08.126

P. Scherrer, Nachr. Ges. Wiss. Göttingen 26, 98 (1918)

J.I. Langford, A.J.C. Wilson, J. Appl. Cryst. 11, 102 (1978). https://doi.org/10.1107/S0021889878012844

V. Uvarov, I. Popov, Mater. Charact. 85, 111 (2013). https://doi.org/10.1016/j.matchar.2013.09.002

V. Boiko, Z. Dai, M. Markowska, C. Leonelli, C. Mortalò, F. Armetta, F. Ursi, G. Nasillo, M.L. Saladino, D. Hreniak, Sci. Rep. (2021). https://doi.org/10.1038/s41598-020-80335-9

O. Mondal, M. Pal, R. Singh, D. Sen, S. Mazumder, M. Pal, J. Appl. Cryst. 48, 836 (2015). https://doi.org/10.1107/S1600576715006664

T.M.K. Thandavan, S.M.A. Gani, C.S. Wong, R.M. Nor, J Nondestruct Eval. 34, 1 (2015)

A.B. Andrade, N.S. Ferreira, M.E.G. Valerio, RSC Adv. 7, 26839 (2017). https://doi.org/10.1039/C7RA01582H

M. Alagiri, S. Ponnusamy, C. Muthamizhchelvan, J. Mater. Sci. 23, 728 (2012). https://doi.org/10.1007/s10854-011-0479-6

M. El-Kemary, N. Nagy, I. El-Mehasseb, Mater. Sci. Semicond. Process. 16, 1747 (2013). https://doi.org/10.1016/j.mssp.2013.05.018

S. Agrawal, A. Parveen, A. Azam, J. Lumin. 184, 250 (2017). https://doi.org/10.1016/j.jlumin.2016.12.035

K. Varunkumar, R. Hussain, G. Hegde, A.S. Ethiraj, Mater. Sci. Semicond. Process. 66, 149 (2017)

M.A. Marselin, N.V. Jaya, Int. J. ChemTech Res. 7, 2654 (2014)

H.T. Rahal, R. Awad, A.M. Abdel-Gaber, D. El-Said Bakeer, J. Nanomater. (2017). https://doi.org/10.1155/2017/7460323

A.D. Khalaji, J. Clust. Sci. 24, 209 (2013). https://doi.org/10.1007/s10876-012-0540-5

Z. Sabouri, N. Fereydouni, A. Akbari, H.A. Hosseini, A. Hashemzadeh, M.S. Amiri, R.K. Oskuee, M. Darroudi, Rare Met. 39, 1134 (2020). https://doi.org/10.1007/s12598-019-01333-z

E.G. Goh, X. Xu, P.G. McCormick, Scr. Mater. 78, 49 (2014). https://doi.org/10.1016/j.scriptamat.2014.01.033

R.K. Gupta, Z. Serbetc, F. Yakuphanoglu, J. Alloys Compd. 515, 96 (2012). https://doi.org/10.1016/j.jallcom.2011.11.098

T. Taşköprü, F. Bayansal, B. Şahin, M. Zor, Philos. Mag. Lett. 95, 32 (2015). https://doi.org/10.1080/14786435.2014.984788

J. Wang, L. Wei, L. Zhang, C. Jiang, E. Siu-Waikong, Y. Zhang, J. Mater. Chem. 22, 8327 (2012). https://doi.org/10.1039/C2JM16934G

K. Baishya, J.S. Ray, P. Dutta, P.P. Das, S.K. Das, Appl. Phys. A. (2018). https://doi.org/10.1007/s00339-018-2097-0

K.N. Patel, M.P. Deshpande, K. Chauhan, P. Rajput, V.P. Gujarati, S. Pandya, V. Sathe, S.H. Chaki, Adv. Powder Technol. 29, 2394 (2018). https://doi.org/10.1016/j.apt.2018.06.018

G. Bharathy, P. Raji, J. Mater. Sci. 28, 17889 (2017). https://doi.org/10.1007/s10854-017-7730-8

Funding

There is no funding for this study.

Author information

Authors and Affiliations

Contributions

MJ: Project Administration, Writing—Original Draft Preparation. KB: Methodology, Data curation. EP: Investigation, Conceptualization. ME, BAK, AM: Resources.

Corresponding author

Ethics declarations

Conflict of interest

This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Jothibas, M., Bharanidharan, K., Paulson, E. et al. Effect of co-dopant proportion on the structural, optical and magnetic properties of pristine NiO nanoparticles synthesized by Sol–gel method. J Mater Sci: Mater Electron 33, 907–919 (2022). https://doi.org/10.1007/s10854-021-07361-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-021-07361-9