Abstract

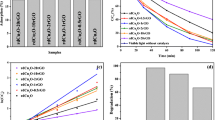

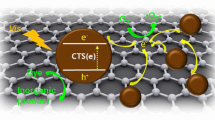

The future catalytic conversion technologies using an inexpensive catalyst is beneficial as they influence energy-saving and harvest-boosted photocatalytic performances toward environmentally carcinogenic pollutants removal. Here, we demonstrate a feasible hydrothermal-assisted strategy to engineer a novel low-dimensional ordered nanoarchitecture comprising Cu ion-modulated CoTe nanoalloy grown onto reduced graphene nanosheets (rGO/Cu/CoTe nanocomposites) is established for toxic dye removal applications. They are advancing the excellence of Cu ion-modulated CoTe nanoalloy catalytic sites encapsulated carbon sheets for effective electron/hole transport, thus boosting catalytic reactions. This obtained integral nanoarchitecture may enhance ion/mass transportation by the greatly ordered crystalline structure and ease the formation of reactive species, radicals, and intermediate products. The holey rGO/Cu/CoTe displays enhanced photocatalytic performance toward visible-light-induced photodegradation of toxic dye Methylene Blue (MB) and Methyl Orange (MO). The 98% and 90.3% degradation efficiencies for MB and MO dyes are observed within 180 min, respectively. Furthermore, the influence of cation modulation on the active catalytic sites could be ascribed by a greatly exposed atom on a lateral surface, consequential from an enormous surface area compared to other chalcogen-based carbon nanocomposites.

Similar content being viewed by others

References

D. Sivaraj, K. Vijayalakshmi, M. Srinivasan, P. Ramasamy, Ceram. Int. 47, 25074 (2021)

W.S. Chai, J.Y. Cheun, P.S. Kumar, M. Mubashir, Z. Majeed, F. Banat, S.-H. Ho, P.L. Show, Journal of Cleaner Production 126589 (2021)

S.Y. Cheng, P.-L. Show, J.C. Juan, J.-S. Chang, B.F. Lau, S.H. Lai, E.P. Ng, H.C. Yian, T.C. Ling, Chemosphere 262, 127829 (2021)

R.M.A. Kanwar, Z.M. Khan, H.U. Farid, Inter. J. Environ. Sci. Technol. 1 (2021)

Z. Zhang, Y. Wu, L. Luo, G. Li, Y. Li, H. Hu, Sci. Total. Environ. 148291 (2021)

N. Li, X. Lu, M. He, X. Duan, B. Yan, G. Chen, S. Wang, J. Hazardous. Mater. 125478 (2021)

G. Yadav, A. Mishra, P. Ghosh, R. Sindhu, V. Vinayak, A. Pugazhendhi, Sci. Total. Environ. 796, 149022 (2021)

A. Padmanaban, G. Murugadoss, N. Venkatesh, S. Hazra, M.R. Kumar, R. Tamilselvi, P. Sakthivel, J. Environ. Chem. Eng. 9, 105976 (2021)

U.G. Akpan, B.H. Hameed, J. Hazard. Mater. 170, 520 (2009)

K. Kasinathan, J. Kennedy, M. Elayaperumal, M. Henini, M. Malik, Sci. Rep. 6, 1 (2016)

K. Kaviyarasu, C.M. Magdalane, D. Jayakumar, Y. Samson, A.K.H. Bashir, M. Maaza, D. Letsholathebe, A.H. Mahmoud, J. Kennedy, J. King. Saud University-Science 32, 1516 (2020)

C.M. Magdalane, K. Kaviyarasu, G.M.A. Priyadharsini, A.K.H. Bashir, N. Mayedwa, N. Matinise, A.B. Isaev, N.A. Al-Dhabi, M.V. Arasu, S. Arokiyaraj, J. Mater. Res. Technol. 8, 2898 (2019)

J. Lin, Z. Luo, J. Liu, P. Li, Mater. Sci. Semicond. Process. 87, 24 (2018)

A. Padmanaban, N. Padmanathan, T. Dhanasekaran, R. Manigandan, S. Srinandhini, P. Sivaprakash, S. Arumugam, V. Narayanan, J. Electroanal. Chem. 877, 114658 (2020)

N. Raza, W. Raza, H. Gul, K.-H. Kim, Environ. Res. 194, 110499 (2021)

L. Nisar, M. Sadaqat, A. Hassan, A. Shah, M. Najam-Ul-Haq, M.N. Ashiq, M.F. Ehsan, K.S. Joya, Fuel 280, 118666 (2020)

L. Zhong, Y. Bao, L. Feng, Electrochim. Acta 321, 134656 (2019)

Z. Zhang, Z. Cai, L. Xia, D. Zhao, F. Fan, Y. Huang, ACS Appl. Mater. Interfaces. 13, 30967 (2021)

W. Zhang, X. Wang, K.W. Wong, W. Zhang, T. Chen, W. Zhao, S. Huang, ACS Appl. Mater. Interfaces. 13, 34134 (2021)

Y. Wang, S. Wang, Y. Wu, Z. Wang, H. Zhang, Z. Cao, J. He, W. Li, Z. Yang, L. Zheng, J. Alloy. Compd. 851, 156733 (2021)

H. Safajou, M. Ghanbari, O. Amiri, H. Khojasteh, F. Namvar, S. Zinatloo-Ajabshir, and M. Salavati-Niasari, Inter. J. Hydrogen Ener. 46, 20534 (2021)

Y. Zeng, J. Zhong, H. Wang, M. Fu, D. Ye, Y. Hu, Chem. Eng. J. 425, 131658 (2021)

M. Imranullah, T. Hussain, R. Ahmad, J.S. Hwang, S. Ahmad, I. Shakir, D.J. Kang, J. Mater. Res. Technol. 15, 623 (2021)

S. Panimalar, R. Uthrakumar, E.T. Selvi, P. Gomathy, C. Inmozhi, K. Kaviyarasu, J. Kennedy, Surfaces and Interfaces 20, 100512 (2020)

D.C. Marcano, D.V. Kosynkin, J.M. Berlin, A. Sinitskii, Z. Sun, A. Slesarev, L.B. Alemany, W. Lu, J.M. Tour, ACS Nano 4, 4806 (2010)

R. Suresh, R. Udayabhaskar, C. Sandoval, E. Ramírez, R.V. Mangalaraja, H.D. Mansilla, D. Contreras, J. Yáñez, New J. Chem. 42, 8485 (2018)

H. Wang, Y. Wang, L. Tan, L. Fang, X. Yang, Z. Huang, J. Li, H. Zhang, Y. Wang, Appl. Catal. B 244, 568 (2019)

T. Dhanasekaran, A. Padmanaban, R. Manigandan, S.P. Kumar, A. Stephen, V. Narayanan, J. Mater. Sci.: Mater. Electron. 28, 12726 (2017)

P. Gnanamozhi, V. Renganathan, S.-M. Chen, V. Pandiyan, M.A. Arockiaraj, N.S. Alharbi, S. Kadaikunnan, J.M. Khaled, K.F. Alanzi, Ceram. Int. 46, 18322 (2020)

Acknowledgements

The author (A.P) recognizes the University of Madras, Department of Inorganic Chemistry, Chennai, for providing the lab facilities. The author recognizes the SSN College of Engineering, Kalavakkam, Tamil Nadu, for financial assistance in SSN PDF. The author acknowledges the NRC, SRMIST, for providing the XPS instrumentation facilities. The author recognizes SRMIST for high-resolution scanning electron microscope (HR-SEM) facility.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Padmanaban, A., Dhanasekaran, T., Dhanavel, S. et al. Rational design of uniformly embedded Cu/CoTe nanoparticles in freestanding rGO sheets for visible light-induced degradation of toxic dyes. J Mater Sci: Mater Electron 33, 9358–9367 (2022). https://doi.org/10.1007/s10854-021-07303-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-021-07303-5