Abstract

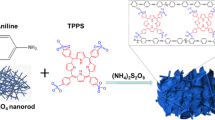

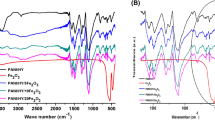

Two different samples of metakaolin one hardened by acid (10 M phosphoric acid) (MP) and another by alkali (Na2SiO3 of silica modulus 1.1) (MS) are reinforced with reduced graphene oxide (rGO) to form nanocomposites (MPr and MSr) and their macrostructural, microstructural and electrochemical properties are investigated. The presence of polymerised aluminosilicates and alumino-silico phosphates are conclusively proved from XRD. The FTIR spectral analysis of the composites and the synthesized cement were also performed. The results confirmed that the addition of an optimal dose of rGO at 2% does not affect the existing gel network of the final product. However, reinforcement by rGO improved the microstructure as seen from the scanning electron microscopy (SEM) analysis of both MP and MS and also resulted in a strength gain of nearly to 10–12% at all ages of curing (1–28 days). The maximum compressive strength attained at 28 days curing in the MPr sample is 79.15 MPa. The electrochemical properties have been studied through cyclic voltammetry and electrochemical impedance spectroscopy and the results are compared. CV curves are symmetrical but slightly deformed, which indicate a good capacitive behaviour. The specific conductance of MPr and MSr is 53.2 F/g and 42.5 F/g, respectively, which is comparatively higher than that of the geopolymer cement, MP (48.27 F/g) and MS (37.5 F/g). The performance of phosphoaluminate sample is better than the alkali-activated sample due to multiple ionic compositions that form Al–O–P units and Si–O–T (T = Si, Al, P) in the network. The conductive mechanism is predominantly governed by ion drift which can be explained through electrolyte distribution in the matrix via pore/channels in addition to fast conducting H+ ions in the phosphoaluminate. The synergistic effect of rGO–metakaolin geopolymers with a desirable compressive strength balanced by good electrochemical properties gives the newly formed material greater potential for energy storage applications.

Similar content being viewed by others

References

T. Gao, L. Shen, M. Shen, F. Chen, L. Liu, L. Gao, Analysis on differences of carbon dioxide emission from cement production and their major determinants. J. Clean. Prod. 103, 160–170 (2015). https://doi.org/10.1016/j.jclepro.2014.11.026

A. Teklay, C. Yin, L. Rosendahl, Flash calcination of kaolinite rich clay and impact of process conditions on the quality of the calcines: a way to reduce CO2 footprint from cement industry. Appl. Energy 162, 1218–1224 (2015). https://doi.org/10.1016/j.apenergy.2015.04.127

Y.-S. Wang, Y. Alrefaei, J.-G. Dai, Silico-aluminophosphate and alkali-aluminosilicate geopolymers: a comparative review. Front. Mater. 6, 106 (2019). https://doi.org/10.3389/fmats.2019.00106

M.B. Mohd Salahuddin, M. Norkhairunnisa, F. Mustapha, A review on thermophysical evaluation of alkali-activated geopolymers. Ceram. Int. 41(3), 4273–4281 (2015). https://doi.org/10.1016/j.ceramint.2014.11.119

J.L. Provis, Geopolymers and other alkali activated materials: why, how, and what?”. Mater. Struct. 47, 11–25 (2014). https://doi.org/10.1617/s11527-013-0211-5

M.R. Wang, D.C. Jia, P.G. He, Y. Zhou, Influence of calcination temperature of kaolin on the structure and properties of final geopolymer. Mater. Lett. 64, 2551–2554 (2010). https://doi.org/10.1016/j.matlet.2010.08.007

L. Mtiaz, S.K. Ur Rehman, S.A. Memon, M.K. Khan, M.F. Javed, A review of recent developments and advances in eco-friendly geopolymer concrete. Appl. Sci. 10(21), 1–56 (2020). https://doi.org/10.3390/app10217838

E.I. Diaz, E.N. Allouche, S. Eklund, Factors affecting the suitability of fly ash as source material for geopolymers. Fuel 89, 992–996 (2010). https://doi.org/10.1016/j.fuel.2009.09.012

M.S. Karuppannan, C. Palanisamy, M.S. Mohammed Farook, M. Natarajan, Study on fly ash and GGBS based oven cured geopolymer concrete. AIP Conf. Proc. 2240, 060001 (2020). https://doi.org/10.1063/5.0011023

A. Albidah, M. Alghannam, H. Abbas, T. Almusallam, Y. Al-salloum, Characteristics of metakaolin-based geopolymer concrete for different mix design parameters. J. Mater. Res. Technol. 10, 84–98 (2021). https://doi.org/10.1016/j.jmrt.2020.11.104

Q. Sun, J. Liu, Fabrication of 3D structures via direct ink writing f kaolin/graphene oxide composite suspensions at ambient temperature. Ceram. Int. 45, 18972–189979 (2019). https://doi.org/10.1016/j.ceramint.2019.06.136

N. Ye, Y. Chen, J. Yang, S. Liang, Y. Hu, B. Xiao, X. Wu, Co-disposal of MSWI fly ash and Bayer red mud using an one-part geopolymeric system. J. Hazard. Mater. 318, 70–78 (2016). https://doi.org/10.1016/j.jhazmat.2016.06.042

K. Behfarnia, N. Salemi, The effects of nano-silica and nano-alumina on frost resistance of normal concrete. Constr. Build. Mater. 48, 580–584 (2013). https://doi.org/10.1016/j.conbuildmat.2013.07.088

S. Lu, X. Wang, Z. Meng, Q. Deng, F. Peng, C. Yu, X. Hu, Y. Zhao, Y. Ke, F. Qi, The mechanical properties, microstructures and mechanism of carbon nanotube-reinforced oil well cement-based nanocomposites. RSC Adv. 9, 26691–26702 (2019). https://doi.org/10.1039/c9ra04723a

K. Gong, Z. Pan, A.H. Korayem, L. Qiu, D. Li, F. Collins, W.H. Duan, Reinforcing effects of graphene oxide on Portland cement paste. J. Mater. Civ. Eng. 27(2), A4014010 (2015). https://doi.org/10.1061/(asce)mt.1943-5533.0001125

T. Huang, Z. Sun, Advances in multifunctional graphene–geopolymer composites. Constr. Build. Mater. 272, 121619 (2021)

A. Mohajerani, D. Suter, T. Jeffrey-Bailey, T. Song, A. Arulrajah, S. Horpibulsuk, D. Law, Recycling waste materials in geopolymer concrete. Clean Technol. Environ. Policy (2019). https://doi.org/10.1007/s10098-018-01660-2

E. Rabiaa, R.A.S. Mohamed, W.H. Sofi, T.A. Tawfik, Developing geopolymer concrete properties by using nanomaterials and steel fibers. Adv. Mater. Sci. Eng. 2020, 1–12 (2020). https://doi.org/10.1155/2020/5186091

X.J. Lee, B.Y.Z. Hiew, K.C. Lai, L.Y. Lee, S. Gan, S. Thangalazhy-Gopakumar, S. Rigby, Review on graphene and its derivatives: synthesis methods and potential industrial implementation. J. Taiwan Inst. Chem. Eng. (2018). https://doi.org/10.1016/j.jtice.2018.10.028

A. Anwar, B.S. Mohammed, M.B. AbdulWahab, M.S. Liew, Enhanced properties of cementitious composite tailored with graphene oxide nanomaterial—a review. Dev. Built Environ. (2019). https://doi.org/10.1016/j.dibe.2019.100002

H. Zhao, K. Min, N.R. Aluru, Size and chirality dependent elastic properties of graphene nanoribbons under uniaxial tension. Nano Lett. 9(8), 3012–3015 (2009). https://doi.org/10.1021/nl901448z

S. Panda, T.K. Rout, A.D. Prusty, P.M. Ajayan, S. Nayak, Electron transfer directed antibacterial properties of graphene oxide on metals. Adv. Mater. 30(7), 1702149 (2018). https://doi.org/10.1002/adma.201702149

T. Wang, M.D.J. Quinn, S.M. Notley, Enhanced electrical, mechanical and thermal properties by exfoliating graphene platelets of larger lateral dimensions. Carbon 129, 191–198 (2018). https://doi.org/10.1016/j.carbon.2017.12.034

P.-H. Shih, T.-N. Do, G. Gumbs, M.-F. Lin, Electronic and optical properties of doped graphene. Physica E 118, 113894 (2020). https://doi.org/10.1016/j.physe.2019.113894

S. Javanbakht, H. Namazi, Doxorubicin loaded carboxymethyl cellulose/graphene quantum dot nanocomposite hydrogel films as a potential anticancer drug delivery system. Mater. Sci. Eng. C 87, 50–59 (2018). https://doi.org/10.1016/j.msec.2018.02.010

Y. Qian, I.M. Ismail, A. Stein, Ultralight, high-surface-area, multifunctional graphene-based aerogels from self-assembly of graphene oxide and resol. Carbon 68, 221–231 (2014). https://doi.org/10.1016/j.carbon.2013.10.082

Y. Wang, Y. Huang, Y. Song, X. Zhang, Y. Ma, J. Liang, Y. Chen, Room-temperature ferromagnetism of graphene. Nano Lett. 9(1), 220–224 (2009). https://doi.org/10.1021/nl802810g

R. He, N. Dai, Z. Wang, Thermal and mechanical properties of geopolymers exposed to high temperature: a literature review. Adv. Civ. Eng. 2020, 1–17 (2020). https://doi.org/10.1155/2020/7532703

M. Pengou, B. Ngouné, H.K. Tchakouté, C.P.N. Nanseu, E. Ngameni, Utilization of geopolymer cements as supercapacitors: influence of the hardeners on their properties. SN Appl. Sci. (2020). https://doi.org/10.1007/s42452-020-2939-1

W. Ma, D. Zhang, Multifunctional structural supercapacitor based on graphene and magnesium phosphate cement. J. Compos. Mater. (2018). https://doi.org/10.1177/0021998318790322

J. Xu, D. Zhang, Multifunctional structural supercapacitor based on graphene and geopolymer. Electrochim. Acta 224, 105–112 (2017). https://doi.org/10.1016/j.electacta.2016.12.045

M. Saafi, L. Tang, J. Fung, M. Rahman, F. Sillars, J. Liggat, X. Zhou, Graphene/fly ash geopolymeric composites as self-sensing structural materials. Smart Mater. Struct. 23(6), 65006 (2014)

S. Yan, P. He, D. Jia, Z. Yang, X. Duan, S. Wang, Y. Zhou, Effect of reduced graphene oxide content on the microstructure and mechanical properties of graphene–geopolymer nanocomposites. Ceram. Int. 42(1), 752–758 (2016). https://doi.org/10.1016/j.ceramint.2015.08.176

H.K. Tchakouté, C.H. Rüscher, E. Kamseu, F. Andreola, C. Leonelli, Influence of the molar concentration of phosphoric acid solution on the properties of metakaolin-phosphate-based geopolymer cements. Appl. Clay Sci. 147, 184–194 (2017)

L. Chen, Z. Wang, Y. Wang, J. Feng, Preparation and properties of alkali activated metakaolin-based geopolymer. Materials 9(9), 767 (2016). https://doi.org/10.3390/ma9090767

J. Baril, J.J. Max, C. Chapados, Infrared titration of phosphoric acid. Can. J. Chem. 78(4), 490–507 (2000)

M. Saafi, L. Tang, J. Fung, M. Rahman, J. Liggat, Enhanced properties of graphene/fly ash geopolymeric composite cement. Cem. Concr. Res. 67, 292–299 (2015). https://doi.org/10.1016/j.cemconres.2014.08.011

S. Yan, P. He, D. Jia, X. Duan, Z. Yang, S. Wang, Y. Zhou, Effects of graphene oxide on the geopolymerization mechanism determined by quenching the reaction at intermediate states. RSC Adv. 7(22), 13498–13508 (2017). https://doi.org/10.1039/c6ra26340b

S. Partschefeld, T. Wiegand, F. Bellmann, A. Osburg, Formation of geopolymers using sodium silicate solution and aluminum orthophosphate. Materials 13(18), 4202 (2020). https://doi.org/10.3390/ma13184202

R. Irfanita, S.S. Desa, M.R. Fahlefy, S. Wahyuni, U. Athiyyah et al., The influence of reduced graphene oxide nanoparticles (rGO NPs) on the microstructure of metakaolin geopolymer. IOP Conf. Ser. Mater. Sci. Eng. 864, 012043 (2020). https://doi.org/10.1088/1757-899x/864/1/012043

Y.J. Zhang, P.Y. He, Y.X. Zhang, H. Chen, A novel electroconductive graphene/fly ashbased geopolymer composite and its photocatalytic performance. Chem. Eng. J. (2017). https://doi.org/10.1016/j.cej.2017.11.171

Acknowledgements

The authors greatly acknowledge the utilization of facilities provided by DST-FIST, Department of Chemistry and SEM facility by NRC, SRM Institute of Science and Technology, Kattankulathur, India. Authors thank the authorities of SRMIST for funding to the research scholars.

Funding

This work was supported by the Department of Science and Technology, the Government of India (GOI), under the Grant DST/TDT/WMT/2017 14/03/18, GOI.

Author information

Authors and Affiliations

Contributions

TR: Investigation, Data curation, Resources and Writing. KJ: Investigation, Methodology, Data curation and Original draft preparation. RJ: Conceptualization, Editing and Supervision, Funding acquisition.

Corresponding author

Ethics declarations

Conflict of interest

All the authors declare that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Revathi, T., Janani, K. & Jeyalakshmi, R. Synthesis of alkali and acid-mediated rGO–metakaolin nano composites for supercapacitor application. J Mater Sci: Mater Electron 33, 9163–9179 (2022). https://doi.org/10.1007/s10854-021-07211-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-021-07211-8