Abstract

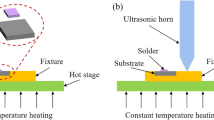

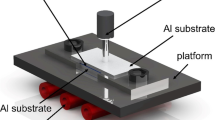

Cu foams with 75% and 98% porosity were employed as reinforcing structures to enhance the performance of the Sn3.0Ag0.5Cu(SAC305)/Cu solder joints. The effects of Cu foam porosity and ultrasonic power on the microstructure and shear properties of solder joints were investigated. The results suggested that the Cu substrate produced excellent metallurgical reactions with both composite solder foils, but more Cu6Sn5 was generated in 75% porosity Cu foam/SAC305 solder joints. The increase of ultrasonic power would accelerate the dissolution of Cu skeleton and effectively refine and homogenize the intermetallic compound grains. Higher power ultrasonic vibration optimized the microstructure of the solder joint, so the shear strength of the joint was increased, but excessive ultrasonic power would cause microcracks at the interface of the solder joint in turn reducing the shear strength.

Similar content being viewed by others

References

H. Qin, X. Zhang, M. Zhou et al., Size and constraint effects on mechanical and fracture behavior of micro-scale Ni/Sn3.0Ag0.5Cu/Ni solder joints. Mater. Sci Eng. A. 617, 14–23 (2014)

B. Li, X. Zhang, Y. Yang et al., Size and constraint effects on interfacial fracture behavior of microscale solder interconnect. Microelectron Reliab. 53(1), 154–163 (2013)

H. Wang, M. Xin, G. Feng et al., Sn concentration on the reactive wetting of high-Pb solder on Cu substrate. Mater. Chem. Phys. 99(2/3), 202–205 (2006)

S. Ahmed et al., Effect of volume in interfacial reaction between eutectic Sn–Pb solder and Cu metallization in microelectronic packaging. Mater. Sci. Eng B. 106(2), 120–125 (2004)

M. Schaefer, R.A. Fournelle, J. Liang, Theory for intermetallic phase growth between cu and liquid Sn-Pb solder based on grain boundary diffusion control. J. Electron. Mater. 27(11), 1167–1176 (1998)

Z. Chen, Y. Shi, Z. Xia et al., Properties of lead-free solder SnAgCu containing minute amounts of rare earth. J. Electron. Mater. 32(4), 235–243 (2003)

J. Yoon, S. Kim, J. Koo et al., Reliability investigation and interfacial reaction of ball-grid-array packages using the lead-free Sn-Cu solder. J. Electron. Mater. 33(10), 1190–1199 (2004)

T. Luan, W. Guo, S. Yang et al., Effect of intermetallic compounds on mechanical properties of copper joints ultrasonic-soldered with Sn-Zn alloy. J. Mater. Process Technol. 248, 123–129 (2017)

L. Satizabal, D. Costa, G. Hainick et al., Microstructural and hardness evaluations of a centrifuged Sn-22Pb casting alloy compared with a lead-free SnAg alloy. Metall. Mater Trans. A. 48(4), 1880–1892 (2017)

F. Hu, Q. Zhang, J. Jiang et al., Influences of Ag addition to Sn-58Bi solder on SnBi/Cu interfacial reaction. Mater. Lett. 214, 142–145 (2017)

J. Janne, Sundelin et al., Mechanical and microstructural properties of SnAgCu solder joints. Mater. Sci. Eng A. 420(1–2), 55–62 (2006)

H. Wang, X. Hu, X. Jiang, Effects of Ni modified MWCNTs on the microstructural evolution and shear strength of Sn-3.0Ag-0.5Cu composite solder joints. Mater. Charact. 163, 110287 (2020)

A.A. El-Daly et al., Tensile deformation behavior and melting property of nano-sized ZnO particles reinforced Sn-3.0Ag-0.5Cu lead-free solder. Mater. Sci. Eng. A. 618, 389 (2014)

A. Gain, Y. Chan, W. Yung, Effect of additions of ZrO2 nano-particles on the microstructure and shear strength of Sn-Ag-Cu solder on Au/Ni metallized Cu pads. Microelectron Reliab. 51(12), 2306–2313 (2011)

L. Liang, J. Zhang, Y. Xu et al., The effect of pressure and orientation on Cu-Cu3Sn interface reliability under isothermal ageing and monotonic traction via molecular dynamics investigation. Mater. Des. 149, 194–204 (2018)

Y. Qiao, H. Ma, F. Yu et al., Quasi-in-situ observation on diffusion anisotropy dominated asymmetrical growth of Cu-Sn IMCs under temperature gradient. Acta Mater. 217, 117168 (2021)

T. Wu, X. Wang, J. Huang et al., Characterization and functional applications of nanoporous Ag foams prepared by chemical dealloying. Metall. Mater. Trans. B. 46(5), 2296–2304 (2015)

C. Zhao, Z. Wu, Heat transfer enhancement of high temperature thermal energy storage using metal foams and expanded graphite. Sol. Energy. Mater. Sol. Cells. 95(2), 636–643 (2011)

H. He, S. Huang, Y. Xiao et al., Diffusion reaction-induced microstructure and strength evolution of Cu joints bonded with Sn-based solder containing Ni-foam. Mater. Lett. 281, 128642 (2020)

J. Kim, R. Kim, H. Kwon, Preparation of copper foam with 3-dimensionally interconnected spherical pore network by electrodeposition. Electrochem. Commun. 10(8), 1148–1151 (2008)

Y. Xiao, Q. Wang, Z. Wang et al., Ultrasonic soldering of Cu alloy using Ni-foam/Sn composite interlayer. Ultrason. Sonochem. 45, 223–230 (2018)

H. He, S. Huang, Y. Ye et al., Microstructure and mechanical properties of Cu joints soldered with a Sn-based composite solder, reinforced by metal foam. J. Alloys. Compd. 845, 156240 (2020)

J. Liu, H. Zhao, Z. Li et al., Study on the microstructure and mechanical properties of Cu-Sn intermetallic joints rapidly formed by ultrasonic-assisted transient liquid phase soldering. J. Alloys. Compd. 692, 552–557 (2017)

H. Zhao, J. Liu, Z. Li et al., Non-interfacial growth of Cu3Sn in Cu/Sn/Cu joints during ultrasonic-assisted transient liquid phase soldering process. Mater. Lett. 186, 283–288 (2017)

R. Chinnam, C. Fauteux, J. Neuenschwander et al., Evolution of the microstructure of Sn-Ag-Cu solder joints exposed to ultrasonic waves during solidification. Acta. Mater. 59(4), 1474–1481 (2011)

W. Guo, T. Luan, J. He et al. Ultrasonic-assisted soldering of fine-grained 7034 aluminum alloy using Sn-Zn solders below 300 °C. Ultrason. Sonochem. 815 (2017)

X. Yi, R. Zhang, X. Hu, Study on the microstructure and mechanical property of Cu-foam modified Sn3.0Ag0.5Cu solder joints by ultrasonic-assisted soldering. J. Manuf. Process. 64, 508–517 (2021)

M. Yang, H. Ji, S. Wang et al., Effects of Ag content on the interfacial reactions between liquid Sn-Ag-Cu solders and Cu substrates during soldering. J. Alloys. Compd. 679, 18–25 (2016)

Z. Li, Z. Xu, M. Lin et al., Cavitation at filler metal/substrate interface during ultrasonic-assisted soldering. Part I: Cavitation characteristics. Ultrason. Sonochem. 49, 249–259 (2018)

Y. Tang, Q. Guo, S. Luo et al., Formation and growth of interfacial intermetallics in Sn-0.3Ag-0.7Cu-xCeO2/Cu solder joints during the reflow process. J. Alloys. Compd. 778, 741–755 (2018)

V. Belova, D. Gorin, D.G. Shchukin et al. Selective ultrasonic cavitation on patterned hydrophobic surfaces. Angew. Chem. Int. Ed. 49(39) (2010)

H. Ji, Q. Wang, M. Li et al., Ultrafine-grain and isotropic Cu/SAC305/Cu solder interconnects fabricated by high-intensity ultrasound-assisted solidification. J. Electron. Mater. 43(7), 2467–2478 (2014)

X. Hu, T. Xu, M. Leon et al., Microstructure evolution and shear fracture behavior of aged Sn3Ag0.5Cu/Cu solder joints. Mater. Sci. Eng. A. 673, 167–177 (2016)

S. Choudhury, L. Ladani, Local shear stress-strain response of Sn-3.5Ag/Cu solder joint with high fraction of intermetallic compounds: experimental analysis. J. Alloys. Compd. 680, 665–676 (2016)

L. Wegner, L. Gibson, The fracture toughness behaviour of interpenetrating phase composites. Int. J. Mech. Sci. 43(8), 1771–1791 (2001)

Acknowledgements

This work was supported by the National Natural Science Foundation of China (No. 51765040).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Declarations

We declare that we have no financial and personal relationships with other people or organizations that can in appropriately influence our work.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Mao, X., Zhang, R., Yi, X. et al. Study on the performance of Cu foam with different porosity on SAC305 solder joints under ultrasonic-assisted soldering. J Mater Sci: Mater Electron 32, 28108–28118 (2021). https://doi.org/10.1007/s10854-021-07186-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-021-07186-6