Abstract

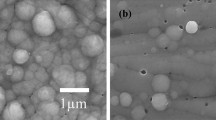

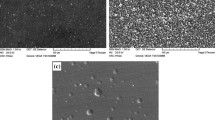

In this paper, the Ni–Fe–P ternary alloy coating was fabricated by electroless deposition and the process parameters of coating preparation were investigated in detail via response surface methodology. The optimal bath temperature and pH for Ni–Fe–P ternary alloy coatings were determined by the central composite design with two center points and the statistical model was established to identify the optimal process conditions for Ni–Fe–P ternary alloy coating. The micro-structure of Ni–Fe–P coatings was investigated by scanning electron microscope. The dispersive spectroscopy and X-ray diffraction were used to study the chemical composition of the coatings. The electrochemical impedance spectroscopy and the potential polarization techniques were used to research its corrosion resistance in 3.5 wt.% NaCl solution. The results show that the coating has the optimal corrosion resistance while the bath temperature was 85 °C and bath pH was 8.

Similar content being viewed by others

References

N. Attarzadeh, M. Molaei, K. Babaei, A. Fattah-alhosseini, New promising ceramic coatings for corrosion and wear protection of steels: a review. Surf. Interfaces (2021). https://doi.org/10.1016/j.surfin.2021.100997

M.F. Montemor, Functional and smart coatings for corrosion protection: a review of recent advances. Surf. Coat. Technol. (2014). https://doi.org/10.1016/j.surfcoat.2014.06.031

D. Wang, G.R. Bierwagen, Sol-gel coatings on metals for corrosion protection. Prog. Org. Coat. (2009). https://doi.org/10.1016/j.porgcoat.2008.08.010

R. Rajkumar, C. Vedhi, A study of corrosion protection efficiency of silica nanoparticles acrylic coated on mild steel electrode. Vacuum (2019). https://doi.org/10.1016/j.vacuum.2018.12.005

B. Liu, S. Yan, Y. He, H. Li, Y. Fan, T. He, Y. Xiang, Preparation of Ni-W-eGO composite coatings and investigation of its mechanical properties and corrosion resistance. Colloids. Surf. A Physicochem. Eng. Asp. (2021). https://doi.org/10.1016/j.colsurfa.2021.127385

Y.C. Lin, S. Liu, Robust ZnO nanowire photoanodes with oxygen vacancies for efficient photoelectrochemical cathodic protection. Appl. Surf. Sci. (2021). https://doi.org/10.1016/j.apsusc.2021.150694

F. Pessu, R. Barker, F. Chang, T. Chen, A. Neville, Iron sulphide formation and interaction with corrosion inhibitor in H2S-containing environments. J. Pet. Sci. Eng. (2021). https://doi.org/10.1016/j.petrol.2021.109152

H.J. Li, Y. He, P.Y. Luo, Y. Fan, T. He, Y.H. Zhang, Y.X. Xiang, Y.H. He, R.X. Song, Fabrication of the ZrC reinforced Ni-W composite coating and exploration of its mechanical properties and corrosion resistance. Surf. Coat. Technol. (2020). https://doi.org/10.1016/j.surfcoat.2021.127413

B. Li, T. Mei, S. Du, W. Zhang, Synthesis of Ni–Fe and Ni–Fe/ZrO2 composite coating and evaluation of its structural and corrosion resistance. Mater. Chem. Phys. (2020). https://doi.org/10.1016/j.matchemphys.2019.122595

R.X. Song, S.H. Zhang, Y. He, H. Li, Y. Fan, T. He, Y.H. Zhang, Y.X. Xiang, H. Zhang, Effect of H-MWCNTs addition on anti-corrosion performance and mechanical character of Ni-Cu/H-MWCNTs composite coatings prepared by pulse electrodeposition technique. Colloids. Surf. A: Physicochem. Eng. Asp. (2021). https://doi.org/10.1016/j.colsurfa.2021.127519

Y.H. Zhang, S.H. Zhang, Y. He, H.J. Li, T. He, Y. Fan, H.L. Zhang, Mechanical properties and corrosion resistance of pulse electrodeposited Ni-B/B4C composite coatings. Surf. Coat. Technol. (2021). https://doi.org/10.1016/j.surfcoat.2021.127458

W.J. Cheong, B.L. Luan, D.W. Shoesmith, The effects of stabilizers on the bath stability of electroless Ni deposition and the deposit. Appl. Surf. Sci. (2004). https://doi.org/10.1016/j.apsusc.2004.02.003

H. Daneshmand, A. Sazgar, M. Araghchi, Fabrication of robust and versatile superhydrophobic coating by two-step spray method: An experimental and molecular dynamics simulation study. Appl. Surf. Sci. (2021). https://doi.org/10.1016/j.apsusc.2021.150825

O. Kilanko, O.S.I. Fayomi, A.A. Sode, Anticorrosion effect of silicon nitride and zirconium diboride composite on Ni–P–Zn electroless deposition on mild steel. J. Bio- and Tribo-Corrosion (2020). https://doi.org/10.1007/s40735-020-00392-5

S. Sadreddini, A. Afshar, M.A. Jazani, Tribological properties of Ni–P–SiO2 nanocomposite coating on aluminum. Colloid J. (2015). https://doi.org/10.1134/s1061933x15050166

D. Dong, X.H. Chen, W.T. Xiao, G.B. Yang, P.Y. Zhang, Preparation and properties of electroless Ni–P–SiO2 composite coatings. Appl. Surf. Sci. (2009). https://doi.org/10.1016/j.apsusc.2009.03.039

C.S. Ramesh, R. Keshavamurthy, B.H. Channabasappa, A. Ahmed, Microstructure and mechanical properties of Ni–P coated Si3N4 reinforced Al6061 composites. Mater. Sci. Eng. A-Struct. (2009). https://doi.org/10.1016/j.msea.2008.10.012

F.J. He, Y.Z. Fang, S.J. Jin, The study of corrosion-wear mechanism of Ni-W-P alloy. Wear (2014). https://doi.org/10.1016/j.wear.2013.12.024

B.K. Kim, S.K. Kim, S.K. Cho, J.J. Kim, Enhanced catalytic activity of electrodeposited Ni-Cu-P toward oxygen evolution reaction. Appl. Catal. B. (2018). https://doi.org/10.1016/j.apcatb.2018.05.082

Z.G. An, J.J. Zhang, Sl. Pan, Fabrication of glass/Ni–Fe–P ternary alloy core/shell composite hollow microspheres through a modified electroless plating process. Appl. Surf. Sci. (2008). https://doi.org/10.1016/j.apsusc.2008.07.067

A.E. Fetohi, R.M.A. Hameed, K.M. El-Khatib, E.R. Souaya, Ni-P and Ni-Co-P coated aluminum alloy 5251 substrates as metallic bipolar plates for PEM fuel cell applications. Int. J. Hydrog. Energy. (2012). https://doi.org/10.1016/j.ijhydene.2012.01.145

C. Shi, L. Wang, L. Wang, Preparation of corrosion-resistant, EMI shielding and magnetic veneer-based composite via Ni–Fe–P alloy deposition. J. Mater. Sci. Mater. Electron. (2015). https://doi.org/10.1007/s10854-015-3331-6

X. Yan, J. Sun, Y. Wang, J. Yang, A Fe-promoted Ni–P amorphous alloy catalyst (Ni–Fe–P) for liquid phase hydrogenation of m- and p-chloronitrobenzene. J. Mol. Catal. A: Chem. (2006). https://doi.org/10.1016/j.molcata.2006.01.060

Q. Zhang, L. Ning, C. Wang, M. Wang, Y. Shen, Y. Yan, Fabrication and characterization of bio-based shielding material with dissimilar surface resistivity prepared by electroless Ni–Fe–P alloy plating on bamboo (N. affinis). J. Mater. Sci. Mater. Electron. (2019). https://doi.org/10.1007/s10854-019-02476-6

H.J.M. Soares, O.S. Campos, D.F. Dias, P.N.S. Casciano, P. de Lima-Neto, A.N. Correia, Chemical, morphological and corrosion characterisations of electrodeposited Ni-Fe-P coatings. Electrochim. Acta. (2018). https://doi.org/10.1016/j.electacta.2018.07.151

L.L. Wang, L.H. Zhao, G. Huang, Composition, structure and corrosion characteristics of Ni-Fe-P and Ni-Fe-P-B alloy deposits prepared by electroless plating. Surf. Coat. Technol. (2000). https://doi.org/10.1016/S0257-8972(00)00545-4

F.L.G. Silva, J.R. Garcia, V.G.M. Cruz, A.S. Luna, D.C.B. Lago, L.F. Senna, Response surface analysis to evaluate the influence of deposition parameters on the electrodeposition of Cu-Co alloys in citrate medium. J. Appl. Electrochem. (2008). https://doi.org/10.1007/s10800-008-9630-3

J. Mangas-Murillo, E.M. Cuerda-Correa, J.R. Dominguez, A. Macias-Garcia, E. Bernalte, Electrical resistivity of YSZ-coated stainless steel electrodes. A study by response surface methodology. J. Alloys Compd. (2013). https://doi.org/10.1016/j.jallcom.2013.05.086

E. Yucel, N. Guler, Y. Yucel, Optimization of deposition conditions of CdS thin films using response surface methodology. J. Alloys Compd. (2014). https://doi.org/10.1016/j.jallcom.2013.11.067

H. Farnoush, D.H. Fatmehsari, J.A. Mohandesi, H. Abdoli, Evaluation of strengthening behavior of Al-AlN nanostructured composite by the use of modified Heckel model and response surface methodology. J. Alloys Compd. (2012). https://doi.org/10.1016/j.jallcom.2011.11.138

G. Chen, J. Chen, C. Srinivasakannan, J.H. Peng, Application of response surface methodology for optimization of the synthesis of synthetic rutile from titania slag. Appl. Surf. Sci. (2012). https://doi.org/10.1016/j.apsusc.2011.11.039

H.T. Bai, Y.Q. Wang, Y. Ma, Q.B. Zhang, N.S. Zhang, Effect of CO2 partial pressure on the corrosion behavior of J55 carbon steel in 30% crude oil/brine mixture. Materials (2018). https://doi.org/10.3390/ma11091765

L. Liu, H. Zhang, H. Zheng, J. Peng, P. Gong, X. Wang, Z. Chen, X. Cao, Influence of crystalline structure on diffusion barrier property of electroless Ni–Fe–P coatings in Zn–Al solder interconnects. J. Alloys Compd. (2019). https://doi.org/10.1016/j.jallcom.2019.06.384

L.M. Abrantes, J.P. Correia, On the mechanism of electroless Ni-P plating. J. Electrochem. Soc. (1994). https://doi.org/10.1149/1.2055125

M.E. Touhami, E. Chassaing, M. Cherkaoui, Kinetics of the autocatalytic deposition of Ni-P alloys in ammoniacal solutions. Electrochim. Acta. (1998). https://doi.org/10.1016/S0013-4686(97)00322-8

A.L.M. Oliveira, J.D. Costa, M.B. de Sousa, J.J.N. Alves, A.R.N. Campos, R.A.C. Santana, S. Prasad, Studies on electrodeposition and characterization of the Ni–W–Fe alloys coatings. J. Alloys Compd. (2015). https://doi.org/10.1016/j.jallcom.2014.09.087

S.A. Ataie, A. Zakeri, RSM optimization of pulse electrodeposition of Zn-Ni-Al2O3 nanocomposites under ultrasound irradiation. Surf. Coat. Technol (2019). https://doi.org/10.1016/j.surfcoat.2018.12.063

J.X. Kang, W.Z. Zhao, G.F. Zhang, Influence of electrodeposition parameters on the deposition rate and microhardness of nanocrystalline Ni coatings. Surf. Coat. Technol (2009). https://doi.org/10.1016/j.surfcoat.2009.01.003

I.V. Petukhov, M.G. Shcherban, N.E. Skryabina, N.E. Skryabina, Corrosion and electrochemical behavior of Ni–P coatings in 0.5 M H2SO4. Prot. Met. (2002). https://doi.org/10.1023/A:1019669503487

B. Akteke-Öztürk, G.-W. Weber, G. Köksal, Generalized desirability functions: a structural and topological analysis of desirability functions. Optimization (2019). https://doi.org/10.1080/02331934.2019.1570192

Acknowledgements

Open Fund (PLN161, PLN201806) of State Key Laboratory of Oil and Gas Reservoir Geology and Exploitation (Southwest Petroleum University) and the National Natural Science Foundation of China (51774245) financially supported this work.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhang, Z., Bai, Y., He, Y. et al. Using RSM optimization to fabricate Ni–Fe–P ternary alloy electroless coating and explore its corrosion properties. J Mater Sci: Mater Electron 32, 26412–26424 (2021). https://doi.org/10.1007/s10854-021-07020-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-021-07020-z