Abstract

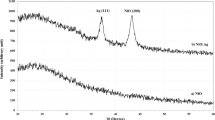

The LCMO: Ag0.2 thin film was grown on the tilted LAO substrate by pulsed laser technology. The structural and electrical properties of the thin film were studied with different deposition times. The X-Ray diffraction analysis demonstrated that all film samples showed exhibit mixed growth and have high crystalline quality. The surface morphology of the films was characterized by atomic force microscopy, and the surface roughness of the films decreased as the deposition time increased. Electrical properties tests show that the peak voltages Up of LIV signals of the films reach their maximum at a deposition time of 10 min, while it also having the TCRmax = 18.43%·K−1. The testing results show that the presence of optimal film thickness can enhance the anisotropic Seebeck coefficient of the film, which in turn improves the film properties.

Similar content being viewed by others

References

P. Schiffer, A.P. Ramirez, W. Bao, S.W. Cheong, Phys Rev Lett 75, 3336 (1995). https://doi.org/10.1103/PhysRevLett.75.3336

Y.B. Zhang, S. Li, C.Q. Sun, W. Gao, Mater. Sci. Eng., B 98, 54 (2003). https://doi.org/10.1016/s0921-5107(02)00758-4

T.A. Mellan, F. Corà, R. Grau-Crespo, S. Ismail-Beigi, Phys. Rev. B (2015). https://doi.org/10.1103/PhysRevB.92.085151

D. Xian-Lin, W. Gen-Shui, C. Ying, T. Xiao-Dong, Z. Yuan-Yuan, J. Inorgan. Mater. (2016). https://doi.org/10.15541/jim20150397

G. Jung, V. Markovich, Y. Yuzhelevski et al., J. Magn. Magn. Mater. 272–276, 1800 (2004). https://doi.org/10.1016/j.jmmm.2003.12.1049

R.L. Zhang, Y. Feng, W.H. Song et al., J. Magn. Magn. Mater. 281, 318 (2004). https://doi.org/10.1016/j.jmmm.2004.04.121

D.H. Manh, N.C. Thuan, P.T. Phong, L.V. Hong, N.X. Phuc, J. Alloy. Compd. 479, 828 (2009). https://doi.org/10.1016/j.jallcom.2009.01.049

U.K.G.A. Gaur, K. Yadav, G.D. Varma, J. Optoelectron. Adv. Mater. 4, 989 (2010)

M. Orvatinia, M. Heydarianasl, Sens. Actuators, A 174, 52 (2012). https://doi.org/10.1016/j.sna.2011.11.026

D. Fan, Q. Li, Y. Xuan, H. Tan, J. Fang, Appl. Therm. Eng. 51, 255 (2013). https://doi.org/10.1016/j.applthermaleng.2012.07.046

T.H. Elbio Dagotto, Adriana Moreo, Phys. Rep. 344, 1 (2001)

E. Rozenberg, M. Auslender, A.I. Shames, Y.M. Mukovskii, E. Sominski, A. Gedanken, J. Non-Cryst. Solids 354, 5282 (2008). https://doi.org/10.1016/j.jnoncrysol.2008.05.087

P. Srivastava, O.N. Srivastava, H.K. Singh, P.K. Siwach, J. Alloy. Compd. 459, 61 (2008). https://doi.org/10.1016/j.jallcom.2007.05.033

G. Venkataiah, D.C. Krishna, M. Vithal et al., Physica B 357, 370 (2005). https://doi.org/10.1016/j.physb.2004.12.001

G. Li, H.D. Zhou, S.J. Feng, X.J. Fan, X.G. Li, Z.D. Wang, J. Appl. Phys. 92, 1406 (2002). https://doi.org/10.1063/1.1490153

F.L. Tang, X. Zhang, J. Phys.: Condens. Matter 18, 7851 (2006). https://doi.org/10.1088/0953-8984/18/34/001

F.-L. Tang, Y.-X. Hu, W.-J. Lu et al., J. Magn. Magn. Mater. 333, 8 (2013). https://doi.org/10.1016/j.jmmm.2012.12.032

C.L. Chang, A. Kleinhammes, W.G. Moulton, L.R. Testardi, Phys Rev B Condens Matter 41, 11564 (1990). https://doi.org/10.1103/physrevb.41.11564

X. Ding, Q.M. Chen, J. Ma, M. Theingi, Y.J. Li, H. Zhang, Key Eng. Mater. 519, 184 (2012)

H. Lengfellner, S. Zeuner, W. Prettl, K.F. Renk, Europhys. Lett. (EPL) 25, 375 (1994). https://doi.org/10.1209/0295-5075/25/5/011

X.H.L.H.-U. Habermeiera, P.X. Zhang, B. Leibold, Solid State Commun. 110, 473 (1999)

P.X. Zhang, C. Wang, S.L. Tan, H. Zhang, H.U. Habermeier, J. Cryst. Growth 310, 2732 (2008). https://doi.org/10.1016/j.jcrysgro.2008.01.044

R. Gross, L. Alff, B. Buchner et al., J. Magn. Magn. Mater. 211, 150 (2000). https://doi.org/10.1016/s0304-8853(99)00727-1

V.P.S. Awana, R. Tripathi, S. Balamurugan, H. Kishan, E. Takayama-Muromachi, Solid State Commun. 140, 410 (2006). https://doi.org/10.1016/j.ssc.2006.09.021

P.-X. Zhang, S.-J. Zhu, X. Liu, J.-B. Peng, T.W. Kim, H.U. Habermeier, Jpn. J. Appl. Phys. 45, 727 (2006). https://doi.org/10.1143/jjap.45.727

J.H. Kim, A.M. Grishin, H.H. Radamson, J. Appl. Phys. (2006). https://doi.org/10.1063/1.2150260

Y.-P. Yi-Zhi, L. Xiang, C. Qing-Ming, J. Inorg. Mater. 29, 754 (2014). https://doi.org/10.3724/SP.J.1077.2014.13562

A. Purohit, S. Chander, S.P. Nehra, C. Lal, M.S. Dhaka, Opt. Mater. 47, 345 (2015). https://doi.org/10.1016/j.optmat.2015.05.053

Q.Y. Xie, X.S. Wu, J. Li, B. Lv, J. Gao, Thin Solid Films 545, 89 (2013). https://doi.org/10.1016/j.tsf.2013.07.036

A.M.B. Vengalis, F. Anisimovas, R. Butkute, L. Dapkus, A. Kindurys, J. Magnet. Magnet. Mater. 211, 35 (2000)

D. Rasic, R. Sachan, N.K. Temizer, J. Prater, J. Narayan, ACS Appl. Mater. Interfaces 10, 21001 (2018). https://doi.org/10.1021/acsami.8b05929

J. Zhao, C. Liu, J. Li et al., AIP Adv. (2019). https://doi.org/10.1063/1.5088738

Acknowledgements

This work was supported by the National Natural Science Foundation of China (No. 11564021).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

No conflict of interest exists in the submission of this manuscript, and manuscript is approved by all authors for publication.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Qi, L., Li, Y., Li, Z. et al. Electrical properties of La0.72Ca0.28MnO3: Ag0.2 thin films of different deposition time prepared by deposited pulsed laser method. J Mater Sci: Mater Electron 32, 22999–23006 (2021). https://doi.org/10.1007/s10854-021-06784-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-021-06784-8