Abstract

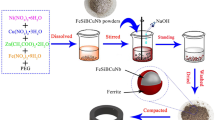

Herein a double shells structure was proposed to overcome the drawbacks such as poor heat resistance, incomplete insulation and high core loss coating of iron-based soft magnetic composites (SMCs) with single shell structure. The surface of the iron powder was coated with a double shells structure composed of an inner phosphate coating and an outer SiO2 coating through phosphating and hydrolysis successively. Subsequently, the effects of different SiO2 addition amount on the microstructure of iron powder and magnetic properties of SMCs were studied. The introduction of SiO2 in the double shells structure inhibited the decomposition and failure of phosphating layer after being annealed at a high temperature. The iron powder coated with the phosphate-SiO2 insulating layer was still effective after annealing in a N2 atmosphere at 570 °C, achieving the purpose of eliminating residual stress and improving magnetic properties. The optimal process parameters were set at 0.2 wt% phosphoric acid and 0.5 wt% tetraethyl orthosilicate to fabricate the phosphate-SiO2 double shells. The iron-based SMCs presented excellent magnetic properties with Bs of 1.29 T and Ps of 169.2 W/kg (measured at 1 T and 1 kHz). In addition, the core loss of SMCs introduced with SiO2 is 83% lower than that of SMCs produced by the phosphating process. This paper provides a feasible method for improving the magnetic properties of SMCs.

Similar content being viewed by others

Data availability

The data sets supporting the results of this article are included within the article.

References

Y. Peng, J. Nie, W. Zhang, J. Ma, C. Bao, Y. Cao, J. Magn. Magn. Mater. 399, 88 (2016)

S. Wu, A. Sun, Z. Lu, C. Cheng, X. Gao, J. Magn. Magn. Mater. 381, 451 (2015)

A.H. Taghvaei, H. Shokrollahi, K. Janghorban, J. Magn. Magn. Mater. 321, 3926 (2009)

L. Sun, Z. Shi, B. He, H. Wang, S. Liu, M. Huang, J. Shi, D. Dastan, H. Wang, Adv. Funct. Mater. (2021). https://doi.org/10.1002/adfm.202100280

S. Sun, Z. Shi, L. Sun, L. Liang, D. Dastan, B. He, H. Wang, M. Huang, R. Fan, A.C.S. Appl, ACS Appl. Mater. Interfaces 13, 27522 (2021)

J. Lei, J. Zheng, H. Zheng, L. Qiao, Y. Ying, W. Cai, W. Li, J. Yu, M. Lin, S. Che, J. Magn. Magn. Mater. 472, 7 (2019)

T.A. Laxminarayana, S.K. Manna, B.G. Fernandes, N. Venkataramani, Phys. Procedia 75, 1396 (2015)

M. Streckova, R. Bures, M. Faberova, L. Medvecky, J. Fuzer, P. Kollar, Chin. J. Chem. Eng. 23, 736 (2015)

S. Wu, J. Fan, J. Liu, H. Gao, D. Zhang, A. Sun, J. Supercond. Nov. Magn. 31, 587 (2018)

B. Yang, Z. Wu, Z. Zou, R. Yu, J. Phys. D Appl. Phys. 43, 365003 (2010)

J. Zheng, H. Zheng, J. Lei, Y. Ying, L. Qiao, W. Cai, W. Li, J. Yu, Y. Tang, S. Che, J. Magn. Magn. Mater. 499, 166255 (2020)

R. Bureš, M. Fáberová, P. Kollár, J. Füzer, S. Dobák, F. Onderko, P. Kurek, Acta Phys. Pol. A 131, 780 (2017)

L. Qian, J. Peng, Z. Xiang, Y. Pan, W. Lu, J. Alloy. Compd. 778, 712 (2019)

M. Huang, C. Wu, Y. Jiang, M. Yan, J. Alloy. Compd. 644, 124 (2015)

H.I. Hsiang, L.F. Fan, J.J. Hung, J. Magn. Magn. Mater. 447, 1 (2018)

Y. Chen, L. Zhang, H. Sun, F. Chen, P. Zhang, X. Qu, E. Fan, J. Alloy. Compd. 813, 152205 (2020)

D. Liu, C. Wu, M. Yan, J. Mater. Sci. 50, 6559 (2015)

A. Du, H. Wang, B. Zhou, C. Zhang, X. Wu, Y. Ge, T. Niu, X. Ji, T. Zhang, Z. Zhang, G. Wu, J. Shen, Chem. Mater. 30, 6849 (2018)

H. Wang, C. Zhang, B. Zhou, Z. Zhang, J. Shen, A. Du, Adv. Compos. Hybrid Mater. 2, 743 (2019)

L. Li, Q. Chen, Z. Gao, Y. Ge, J. Yi, J. Alloy. Compd. 805, 609 (2019)

A.H. Taghvaei, H. Shokrollahi, A. Ebrahimi, K. Janghorban, Mater. Chem. Phys. 116, 247 (2009)

N. Zhao, C. He, J. Liu, H. Gong, T. An, H. Xu, F. Zhao, R. Hu, H. Ma, J. Zhang, J. Solid State Chem. 219, 67 (2014)

A. Du, B. Zhou, J. Shen, S. Xiao, Z. Zhang, C. Liu, M. Zhang, J. Non-Cryst, Solids 355, 175 (2009)

B. Hu, X. Wang, H. Shu, X. Yang, L. Liu, Y. Song, Q. Wei, H. Hu, H. Wu, L. Jiang, X. Liu, Electrochim. Acta 102, 8 (2013)

K. Sun, S. Feng, Q. Jiang, X. Li, Y. Li, R. Fan, Y. An, J. Wang, J. Magn. Magn. Mater. 493, 165705 (2020)

J.L. Grosseau-Poussard, B. Panicaud, F. Pedraza, P.O. Renault, J.F. Silvain, J. Appl. Phys. 94, 784 (2003)

P. Kollár, Z. Birčáková, J. Füzer, R. Bureš, M. Fáberová, J. Magn. Magn. Mater. 327, 146 (2013)

T.D. Shen, U. Harms, R.B. Schwarz, J. Metastab. Nanocryst. Mater. 13, 441 (2002)

H.Ã. Shokrollahi, K. Janghorban, J. Magn. Magn. Mater. 313, 182 (2007)

K. Sun, J. Qin, Z. Wang, Y. An, X. Li, B. Dong, X. Wu, Z. Guo, R. Fan, Surf. Interfaces 21, 100735 (2020)

Acknowledgements

The authors gratefully acknowledge the financial supports by the Science and Technology Commission of Shanghai Municipality (18040501500), the Innovation Program of Shanghai Municipal Education Commission (Grant No. 2019-01-07-00-10-E00053), the National Natural Science Foundation of China (Grant No. 51803119, 51871146 and 51771108), Chenguang Program supported by Shanghai Education Development Foundation and Shanghai Municipal Education Commission (Grant No. 18CG56), the Natural Science Foundation of Shanghai (18ZR1417000) and Shanghai Engineering Technology Research Centre of Deep Offshore Material (19DZ2253100).

Funding

The authors gratefully acknowledge the financial supports by the Science and Technology Commission of Shanghai Municipality (18040501500), the Innovation Program of Shanghai Municipal Education Commission (Grant No. 2019-01-07-00-10-E00053), the National Natural Science Foundation of China (Grant No. 51803119, 51871146 and 51771108), Chenguang Program supported by Shanghai Education Development Foundation and Shanghai Municipal Education Commission (Grant No. 18CG56), the Natural Science Foundation of Shanghai (18ZR1417000) and Shanghai Engineering Technology Research Centre of Deep Offshore Material (19DZ2253100).

Author information

Authors and Affiliations

Contributions

WY: methodology, data curation, validation, writing-original draft. KS: writing-review and editing, project administration, supervision. JT: formal analysis, software, supervision. YL: formal analysis, resources. ZW: resources, software. BL: supervision, validation. RF: supervision, funding acquisition, investigation.

Corresponding authors

Ethics declarations

Conflict of interest

There is no conflict of interest in the submission of this manuscript.

Consent to participate

I would like to declare on behalf of my co-authors that the work described is original research that has not been published previously, and not under consideration for publication elsewhere.

Consent for publication

The manuscript is approved by all authors for publication.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yuan, W., Sun, K., Tian, J. et al. Improved magnetic properties of iron-based soft magnetic composites with a double phosphate-SiO2 shells structure. J Mater Sci: Mater Electron 32, 21472–21482 (2021). https://doi.org/10.1007/s10854-021-06656-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-021-06656-1