Abstract

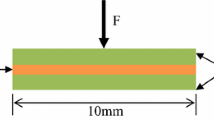

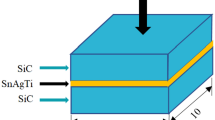

The element diffusion behavior, the interfacial evolution and mechanical properties of the joining of gallium arsenide (GaAs) with Sn3.5Ag4Ti(Ce,Ga) alloy filler at 250 °C in air were investigated. The interfacial microstructure, elemental diffusion and absorption, interface reaction and evolution were analyzed in detail. Titanium (Ti) and gallium (Ga) element were found to obviously take part in the active bonding between GaAs substrate and Sn3.5Ag4Ti(Ce,Ga) alloy filler. According to the transmission electron microscopy analysis, the titanium elements were observed to successively segregate at the interface, while some of the element Ga included in GaAs to dissolve into the molten alloy. In addition, there is a resultant formed discontiniously along the interface which was identified as Ga4Ti5, but no arsenic compounds were observed. The joining mechanisms related to the adsorption and reaction were discussed based on the thermodynamics theories, the molecular dynamic (MD) model and the reaction product controlled (RPC) model. The analysis results show that the RPC model was a special form of MD model, both the chemical reaction and the adsorption of active elements may control the reactive wetting of Sn3.5Ag4Ti(Ce,Ga) filler alloy on GaAs substrate together. In order to better understand the interfacial evolution of bonding, a simple interfacial evolution model between GaAs substrate and Sn3.5Ag4Ti(Ce, Ga) active solder was established. Finally, the effect of holding time on shear strength was investigated and the maximum shear strength of 23.32 MPa was obtained when soldered at 250 °C for 1 h. The interface separation could be caused by the mixed fracture mechanism.

Similar content being viewed by others

Data availability

The data that support the finding of this study are available from the corresponding author upon reasonable request.

References

R.H. van Leest, P. Mulder, G.J. Bauhuis, H. Cheun, H. Lee, W. Yoon, R. van der Heijden, E. Bongers, E. Vlieg, J.J. Schermer, Phys. Chem. Chem. Phys. 19, 7607–7616 (2017)

P. Huo, I. Rey-Stolle, J. Electron. Mater. 45, 2769–2775 (2016)

Y. Ohno, J. Liang, N. Shigekawa, H. Yoshida, S. Takeda, R. Miyagawa, Y. Shimizu, Y. Nagai, Appl. Surf. Sci. 525, 146610 (2020)

E. Higurashi, T. Suga, Electr. Commun. Jpn. 99, 63–71 (2016)

E. Higurashi, K. Okumura, K. Nakasuji, T. Suga, Jpn. J. Appl. Phys. 54, 030207 (2015)

P. Karbownik, A. Trajnerowicz, A. Szerling, A. Wójcik-Jedlińska, M. Wasiak, E. Pruszyńska-Karbownik, K. Kosiel, I. Gronowska, R. Sarzała, M. Bugajski, Opt. Quant. Electron. 47, 893–899 (2015)

T. Li, D. Zhou, Y. Yan, S. Zhang, J. Liu, Mater. Sci. Eng. A 796, 139929 (2020)

L.X. Zhang, B. Zhang, Z. Sun, S.Y. Liu, M. Lei, J.C. Feng, Ceram. Int. 46, 10224–10232 (2020)

C. Xin, J. Yan, Q. Wang, W. Feng, C. Xin, J. Alloy. Compd. 820, 153189 (2020)

D. Liu, K. Zhao, Y. Song, L. Zhang, X. Song, W. Long, Mater. Charact. 157, 109890 (2019)

S.Y. Chang, T.H. Chuang, L.C. Tsao, C.L. Yang, Z.S. Yang, J. Mater. Process. Tech. 202, 22–26 (2008)

S.Y. Chang, L.C. Tsao, M.J. Chiang, T.H. Chuang, C.N. Tung, G.H. Pan, J. Mater. Eng. Perform. 12, 383–389 (2003)

L.C. Tsao, Mater. Sci. Eng. A 565, 63–71 (2013)

L.C. Tsao, J. Mater. Sci. 25, 233–243 (2014)

L.C. Tsao, Mater. Des. 56, 318–324 (2014)

B.Z. Wu, X.S. Leng, Z.Y. Xiu, J.C. Yan, Sci. Rep. 8, 16856 (2018)

L.X. Cheng, G.Y. Li, Z.L. Li, Z.Z. Wu, B. Zhou, J. Mater. Sci. 26, 6004–6012 (2015)

L.X. Cheng, G.Y. Li, X.Q. Wang, Z.L. Li, Z.Z. Wu, Mater. Sci. Eng. A 658, 42–49 (2016)

Y. Liu, J.C. Tedenac, X.P. Su, C. Colinet, J.H. Wang, Calphad 41, 140–149 (2013)

Y.J. Liang, Handbook of Inorganic Thermodynamic Data (Northeastern University Press, Shenyang, 1993), pp. 39–441

D.R. Journal of Physical and Chemical Reference Data (The American Chemical Society and The American Instutute of Physics, 1982), pp. 92–407

R.T. Li, W. Pan, J. Chen, J. Lian, Mater. Sci. Eng. A 335, 21–25 (2002)

T. Sebestyen, I. Mojzes, D. Szigethy, Electron. Lett. 16, 504 (1980)

R.P. Gupta, W.S. Khokle, J. Wuerfl, H.L. Hartnagel, Thin Solid Films 151, L121–L125 (1987)

A.F. Wright, N.A. Modine, J. Appl. Phys. 120, 215705 (2016)

Z.W. Li, J.H. Yin, Materials Fundamentals of Semiconductor Silicon, 2nd edn. (Beijing Chemical Industry Press, Beijing, 2012), pp. 125–136

T.D. Blake, Surfactant Sci. Ser. 49, 251–255 (1993)

Q. Lin, R. Cao, Comp. Mater. Sci. 99, 29–32 (2015)

M. Benhassine, E. Saiz, A.P. Tomsia, J. De Coninck, Acta Mater. 59, 1087–1094 (2011)

S.Y. Chang, T.H. Chuang, C.L. Yang, J. Electron. Mater. 36, 1193–1198 (2007)

Acknowledgements

This research is supported by the National Natural Science Foundation of China [Grant No. 61804057]; and the Science and Technology Planning Project of Guangdong [Grant No. 201803020022].

Funding

This research is supported by the National Natural Science Foundation of China [Grant No. 61804057]; and the Science and Technology Planning Project of Guangdong [Grant No. 201803020022].

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation, data collection and analysis were performed by LXC, XJY, ZZW, and JX. The first draft of the manuscript was written by LXC and GYL, and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

No conflict of interest exits in the submission of this manuscript, and manuscript is approved by all authors and the responsible authorities at the institute for publication.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Cheng, L.X., Yue, X.J., Xia, J. et al. Adsorption and interface reaction in direct active bonding of GaAs to GaAs using Sn–Ag–Ti solder filler. J Mater Sci: Mater Electron 32, 21248–21261 (2021). https://doi.org/10.1007/s10854-021-06627-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-021-06627-6