Abstract

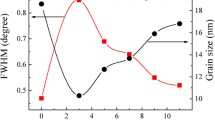

This work presents a methodology based on the WO3/Ag/WO3 (WAW) tri-layer configuration for obtaining indium-free TCOs by RF sputtering at room temperature. The tri-layer performance is shown to be very sensitive to the thickness variations. Through the optimization of the WO3 top layer, it was possible to obtain a combination of thicknesses that allow to maximize the optical transmittance and at the same time lower the sheet resistance, this translates into an excellent compromise between these two properties that are usually antagonists. Using a metallic layer with a thickness that is just at its percolation limit, high electrical conductivity values can be obtained without compromising the optical transmittance. Thickness variation of the dielectric layers in turn, allowed to optimize the transport of the electrons to the metallic film. The overall tri-layer performance was evaluated using multifigure of merit analysis. Our best results were obtained for WO3(40 nm)/Ag(7 nm)/WO3(20 nm) with 1.2 Ω/sq sheet resistance and transmittance above 85%. Therefore, it is possible to obtain a TCO in an indium-free tri-layer WAW configuration at room temperature with good performance that represents a viable alternative that is not restricted by the scarcity of indium.

Similar content being viewed by others

References

M. Frenzel, T. Hirsch, J. Gutzmer, Ore Geol. Rev. 76, 52 (2016)

T.H. Yeh, C.C. Lee, C.J. Shih, G. Kumar, S. Biring, S.W. Liu, Org. Electron. 59, 266 (2018)

Y. Yin, C. Lan, H. Guo, C. Li, ACS Appl. Mater. Interfaces 8, 3861 (2016)

A. Bingel, M. Steglich, P. Naujok, R. Müller, U. Schulz, N. Kaiser, A. Tünnermann, Thin Solid Films 616, 594 (2016)

J. Ho Kim, Y.J. Moon, S.K. Kim, Y.Z. Yoo, T.Y. Seong, Ceram. Int. 41, 14805 (2015)

J. Ho Kim, J. Hwan Lee, S.W. Kim, Y.Z. Yoo, T.Y. Seong, Ceram. Int. 41, 7146 (2015)

S. Kim, J.L. Lee, J. Photonics Energy 2, 021215 (2012)

H. Najafi-Ashtiani, B. Akhavan, F. Jing, M.M. Bilek, ACS Appl. Mater. Interfaces 11, 14871 (2019)

J. Hong, B.-S. Kim, B. Hou, S. Pak, T. Kim, A.-R. Jang, Y. Cho, S. Lee, G.-H. An, J.E. Jang, S.M. Morris, J.I. Sohn, S. Cha, A.C.S. Appl, Mater. Interfaces 13, 4244 (2021)

G. Haacke, J. Appl. Phys. 47, 4086 (1976)

J.A. Mendez-Gamboa, R. Castro-Rodriguez, I.V. Perez-Quintana, R.A. Medina-Esquivel, A. Martel-Arbelo, Thin Solid Films 599, 14 (2016)

H. Li, Y. Lv, X. Zhang, X. Wang, X. Liu, Sol. Energy Mater. Sol. Cells 136, 86 (2015)

S.F. Chen, S.J. Wang, Y.H. Li, Z.A. Zhu, X.T. Hong, J.H. Hu, M.C. Wang, Sensors 18, 2803 (2018)

Y. Yin, T. Gao, Q. Xu, G. Cao, Q. Chen, H. Zhu, C. Lan, C. Li, J. Mater. Chem. A 8, 10973 (2020)

Z. Wang, C. Zhang, R. Gao, D. Chen, S. Tang, J. Zhang, D. Wang, X. Lu, Y. Hao, Sol. Energy Mater. Sol. Cells 127, 193 (2014)

L. Cattin, Y. Lare, M. Makha, M. Fleury, F. Chandezon, T. Abachi, M. Morsli, K. Napo, M. Addou, J.C. Bernède, Sol. Energy Mater. Sol. Cells 117, 103 (2013)

J. Huang, X. Liu, Y. Lu, Y. Zhou, J. Xu, J. Li, H. Wang, J. Fang, Y. Yang, W. Wang, R. Tan, W. Song, Sol. Energy Mater. Sol. Cells 184, 73 (2018)

H. Wei, H. Eilers, J. Phys. Chem. Solids 70, 459 (2009)

G. Ramakrishnan, P.C.M. Planken, Opt. Lett. 36, 2572 (2011)

R.H. Castillo, F. Peñuñuri, D. Canto-Reyes, A.B. Pool, J.A. Mendez-Gamboa, M. Acosta, Mater. Lett. 260, 126913 (2020)

Y.W. Jo, C. Loka, K.S. Lee, J.H. Lim, RSC Adv. 10, 16187 (2020)

D. Rabia, M. Blais, H. Essaidi, N. Stephant, G. Louarn, M. Morsli, S. Touihri, Thin Solid Films 669, 613 (2019)

K. Jeon, H. Youn, S. Kim, S. Shin, M. Yang, Nanoscale Res. Lett. 7, 253 (2012)

H. Essaidi, L. Cattin, Z. El Jouad, S. Touihri, M. Blais, E. Ortega, G. Louarn, M. Morsli, T. Abachi, T. Manoubi, M. Addou, M.A. del Valle, F. Diaz, J.C. Bernède, Vacuum 153, 225 (2018)

X. Liu, X. Guo, Y. Lv, Y. Hu, J. Lin, Y. Fan, N. Zhang, X. Liu, A.C.S. Appl, Mater. Interfaces 10, 18141 (2018)

J. Tauc, R. Grigorovi, A. Vancu, Phys. Status Solidi 15, 627 (1966)

B. Fallahazad, S. Kim, L. Colombo, E. Tutuc, Appl. Phys. Lett. 97, 123105 (2010)

Y. Wang, B. He, H. Wang, J. Xu, T. Ta, W. Li, Q. Wang, S. Yang, Y. Tang, B. Zou, Mater. Lett. 188, 107 (2017)

A.A. Matias Velazquez, D. Canto-Reyes, J.A. Mendez-Gamboa, M. Acosta, Mater. Lett. 245, 65 (2019)

Acknowledgements

This work has been supported by CONACYT-SENER under contract 254667. R. Hernández Castillo, D. Canto-Reyes and Alicia Borges Pool acknowledge CONACYT postgraduate scholarship program. The authors thank the LANNBIO Nano-Biomaterials Laboratory (CINVESTAV- IPN Unidad Merida) for the access to SEM measurements.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Castillo, R.H., Canto-Reyes, D., Pool, A.B. et al. Influence of top layer thickness on the performance of WO3/Ag/WO3-transparent electrodes. J Mater Sci: Mater Electron 32, 19063–19069 (2021). https://doi.org/10.1007/s10854-021-06422-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-021-06422-3