Abstract

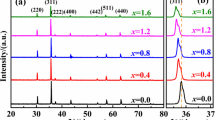

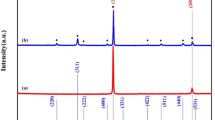

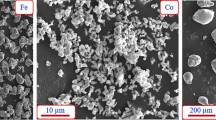

The OH¯/(Co2+, Fe2+) ratio and annealing temperature (Ta) have a great influence on the microstructure and magnetic properties of FeCo alloys. In this work, the OH¯/(Co2+, Fe2+) ratio was first changed from 10:1 to 30:1. When the OH¯/(Co2+, Fe2+) ratio was 20:1, pure FeCo powder samples were obtained. After annealing at 400 °C, the saturation magnetization (Ms), remnant magnetization (Mr), and coercivity (Hc) were 155 emu/g, 15 emu/g, and 210 Oe, respectively. Then the prepared FeCo samples were annealed in the range of 300 °C–600 °C for 5 h. With the increasing of Ta, the better magnetic properties of FeCo powders were observed. When the Ta was 600 °C, the Ms, Mr, and Hc were 202 emu/g, 12 emu/g, and 87 Oe, respectively. When the OH¯/(Co2+, Fe2+) = 20:1 and Ta was 400 °C, the real part of complex permittivity was between 8.2 and 9.5, and the corresponding imaginary part was between − 0.3 and 1.3. Furthermore, the maximum reflection loss (RL) value of FeCo powders (20–30 nm) was − 35.49 dB which showed great potential in corresponding industrial applications.

Similar content being viewed by others

References

M. Salavati-Niasari, F. Farzaneh, M. Ghandi, J. Mol. Catal. A Chem. 186, 101 (2002)

D. Ghanbari, M. Salavati-Niasari, J. Ind. Eng. Chem. 24, 284 (2015)

M. Amiri, M. Salavati-Niasari, A. Akbari, Adv. Colloid Interfac. 265, 29 (2019)

A. Abbasi, D. Ghanbari, M. Salavati-Niasari, M. Hamadanian, J. Mater. Sci. Mater. El. 27, 4800 (2016)

S. Mortazavi-Derazkola, M. Salavati-Niasari, O. Amiri, A. Abbasi, J. Energy Chem. 26, 17 (2017)

H.J. Wu, G.L. Wu, Y.Y. Ren, X.H. Li, L.D. Wang, Chem. Eur. J. 22, 8864 (2016)

N.A. Frey, S. Peng, K. Cheng, S.H. Sun, Chem. Soc. Rev. 38, 2532 (2009)

T.L. Doane, C. Burda, Chem. Soc. Rev. 41, 2885 (2012)

L. Liu, N. He, T. Wu, P. Hu, G. Tong, Chem. Eng. J. 355, 103 (2019)

F. Wang, N. Wang, X. Han, D. Liu, Y. Wang, L. Cui, P. Xu, Y.C. Du, Carbon 145, 701 (2019)

Y. Cheng, G.B. Ji, Z.Y. Li, H.L. Lv, W. Liu, Y. Zhao, J.M. Cao, Y.W. Du, J. Alloy. Compd. 704, 289 (2017)

D.W. Liu, Y.C. Du, P. Xu, N. Liu, Y.H. Wang, H.H. Zhao, L.R. Cui, X.J. Han, J. Mater. Chem. C 7, 5037 (2019)

Z. Wu, K. Pei, L. Xing, X. Yu, W. You, R. Che, Adv. Funct. Mater. 28, 1901448 (2019)

O. Acher, S. Dubourg, Phys. Rev. B 77, 104440 (2008)

M. Koiwa, Philos. Mag. 24, 81 (1971)

D. Kodama, K. Shinoda, K. Sato, Y. Konno, R.J. Joseyphus, K. Motomiya, H. Takahashi, T. Matsumoto, Y. Sato, K. Tohji, B. Jeyadevan, Adv. Mater. 18, 3154 (2006)

F.J. Yang, J.J. Min, Z.W. Kang, S.Y. Tu, H.B. Chen, D.G. Liu, W.J. Li, X.Q. Chen, C.P. Yang, Chem. Phys. Lett. 670, 1 (2017)

R.H. Tang, T. Li, Z.B. Wu, W.P. Cai, H. Jiang, Z.G. Yang, W. Liu, Z.J. Zhang, B. Yang, X.F. Liu, Z.Y. Zou, R.H. Yu, IEEE Trans. Magn. 47, 3456 (2011)

P. Karipoth, A. Thirumurugan, R.J. Joseyphus, J. Colloid. Interf. Sci. 404, 49 (2013)

Z.J. Huba, K.J. Carroll, E.E. Carpenter, J. Appl. Phys. 109, 07B514 (2011)

R.J. Joseyphus, K. Shinoda, D. Kodama, B. Jeyadevan, Mater. Chem. Phys. 123, 487 (2010)

M.R. Wright, An Introduction to Chemical Kinetics (Wiley, Chichester, 2004).

C. Wang, X.J. Han, P. Xu, X.L. Zhang, Y.C. Du, S.R. Hu, J.Y. Wang, X.H. Wang, Appl. Phys. Lett. 98, 072906 (2011)

T. Wu, Y. Liu, X. Zeng, T.T. Cui, Y.T. Zhao, Y. Li, G.X. Tong, A.C.S. Appl, Mater. Interfaces 8, 7370 (2016)

L. Tian, J. Xu, S. Xiao, Vacuum 86, 27 (2011)

C.X. Zhang, J.S. Shi, X.J. Yang, L.L. De, X. Wang, Mater. Chem. Phys. 123, 551 (2010)

Y.T. Lu, Y.J. Chien, C.F. Liu, T.H. You, C.C. Hu, J. Mater. Chem. 5, 21016 (2017)

I.B. Bersuker, Electronic Structure and Properties of Transition Metal Compounds, 2nd edn. (Wiely, New York, 2010), pp. 238–323

A. López-Ortega, M. Estrader, G. Salazar-Alvarez, A.G. Roca, J. Nogués, Phys. Rep. 553, 1 (2015)

X.G. Liu, D.Y. Geng, Z.D. Zhang, Appl. Phys. Lett. 92, 243110 (2008)

T. Liu, X.B. Xie, Y. Pang, S. Kobayashi, J. Mater. Chem. C 4, 1727 (2016)

Q.H. Liu, Q. Cao, H. Bi, C.Y. Liang, K.P. Yuan, W. She, Y.J. Yang, R.C. Che, Adv. Mater. 28, 486 (2016)

Acknowledgements

The authors are grateful for financial support from the National Science Foundation of China (Grant No. 11274101), National Key R&D Program of China (Grant No. 2019YFF01014400), and The Innovation and Enterprise Team Project of Pearl River Talent Plan (Grant No. 2016ZT06G73)

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest. This article does not contain any studies with human participants or animals performed by any of the authors. Informed consent was obtained from all individual participants included in the study.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ke, M., Liao, T., Jia, Y. et al. The microstructure and magnetic properties of FeCo alloys with different OH ¯ /(Co 2+ , Fe 2+ ) ratio and annealing temperature . J Mater Sci: Mater Electron 32, 14156–14163 (2021). https://doi.org/10.1007/s10854-021-05912-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-021-05912-8