Abstract

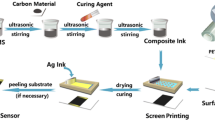

The fabrication of environmentally friendly printed flexible sensors is still an emerging technology, but with vast potential applications. Among the available printing techniques, inkjet printing is considered as a promising technique for flexible electronics because it enables high volume and versatile manufacturing, at low environmental impact. This study demonstrates a simple and facile method of preparing an environmentally benign water-based conductive ink, by dispersing functionalized and non-functionalized multi-walled carbon nanotubes (MWCNTs) in aqueous solution with the help of a biopolymer surfactant. The concentration of CNTs in the ink formulation was varied from 0.25 to 0.75 wt%, and additives such as triton-x 100, polypropylene glycol, and defoamer were added to achieve desirable ink properties. Inkjet printable ink was produced, and it was observed that the conductivity of the printed pattern is dependent on the printing pass. In addition, it was found that as the number of printing layer increases, there is higher synergy between concentration and number of printing pass in F-MWCNTs printed ink to produce higher electrical conductivity, compared to MWCNTs printed ink. Generally, the findings of this study could potentially open opportunities for global economic growth through the applications of printed, low cost and environmentally friendly flexible sensors.

Similar content being viewed by others

References

C. Cano-Raya et al., Chemistry of solid metal-based inks and pastes for printed electronics—a review. Appl. Mater. Today 15, 416–430 (2019)

A.M. Abdelkader et al., Ultraflexible and robust graphene supercapacitors printed on textiles for wearable electronics applications. 2D Mater. 4(3), 035016 (2017)

L. Zhou et al., All-organic active matrix flexible display. 88(8), 083502 (2006)

N. Karim et al., All inkjet-printed graphene-based conductive patterns for wearable e-textile applications. J. Mater. Chem. C 5(44), 11640–11648 (2017)

M.V. Kulkarni et al., Ink-jet printed conducting polyaniline based flexible humidity sensor. Sens. Actuators B 178, 140–143 (2013)

N. Matsuhisa et al., Printable elastic conductors by in situ formation of silver nanoparticles from silver flakes. Nat. Mater. 16(8), 834–840 (2017)

M. Jung et al., All-printed and roll-to-roll-printable 13.56-MHz-operated 1-bit RF tag on plastic foils. IEEE Trans. Electron Devices 57(3), 571–580 (2010)

A. Chauraya et al., Inkjet printed dipole antennas on textiles for wearable communications. IET Microw. Antennas Propag. 7, 760–767 (2013)

G.H. Gelinck et al., Flexible active-matrix displays and shift registers based on solution-processed organic transistors. Nat. Mater. 3(2), 106–110 (2004)

N. Matsuhisa et al., Printable elastic conductors with a high conductivity for electronic textile applications. Nat. Commun. 6(1), 7461 (2015)

H. Menon, R. Aiswarya, K.P. Surendran, Screen printable MWCNT inks for printed electronics. RSC Adv. 7(70), 44076–44081 (2017)

D.J. Finn, M. Lotya, J.N. Coleman, Inkjet printing of silver nanowire networks. ACS Appl. Mater. Interfaces 7(17), 9254–9261 (2015)

E.B. Secor et al., Gravure printing of graphene for large-area flexible electronics. Adv. Mater. 26(26), 4533–4538 (2014)

M.F.L. De Volder et al., Carbon nanotubes: present and future commercial applications. Science 339(6119), 535–539 (2013)

S. Azoubel, S. Shemesh, S. Magdassi, Flexible electroluminescent device with inkjet-printed carbon nanotube electrodes. Nanotechnology 23(34), 344003 (2012)

N. Karim et al., All Inkjet-printed graphene-silver composite ink on textiles for highly conductive wearable electronics applications. Sci. Rep. 9(1), 8035 (2019)

E.B. Secor et al., Inkjet printing of high conductivity, flexible graphene patterns. J. Phys. Chem. Lett. 4(8), 1347–1351 (2013)

M.N. Karim et al., Towards UV-curable inkjet printing of biodegradable poly (lactic acid) fabrics. J. Mater. Sci. 50(13), 4576–4585 (2015)

S. Kholghi Eshkalak et al., A review on inkjet printing of CNT composites for smart applications. Appl. Mater. Today 9, 372–386 (2017)

F. Loghin et al., A facile and efficient protocol for preparing residual-free single-walled carbon nanotube films for stable sensing applications. Nanomaterials 9(3), 471 (2019)

A.N. Omrani et al., Effects of multi walled carbon nanotubes shape and size on thermal conductivity and viscosity of nanofluids. Diam. Relat. Mater. 93, 96–104 (2019)

L. Chen et al., Rheological behaviors of nanofluids containing multi-walled carbon nanotube. J. Dispersion Sci. Technol. 32(4), 550–554 (2011)

L. Maillaud et al., Effect of the rheological properties of carbon nanotube dispersions on the processing and properties of transparent conductive electrodes. Langmuir 31(21), 5928–5934 (2015)

E. Patrice et al., Shear history effect on the viscosity of carbon nanotubes water-based nanofluid. Curr. Nanosci. 9(2), 225–230 (2013)

N.H. Ismail, J.O. Akindoyo, M. Mariatti, Solvent mediated dispersion of carbon nanotubes for glass fibre surface modification—suspensions stability and its effects on mechanical, interlaminar and dynamic mechanical properties of modified glass fibre reinforced epoxy laminates. Compos. Part A: Appl. Sci. Manuf. 139, 106091 (2020)

Z. Xu et al., Efficient dispersion of carbon nanotube by synergistic effects of sisal cellulose nano-fiber and graphene oxide. Compos. Interfaces 24(3), 291–305 (2017)

Y. Liu et al., Aqueous dispersion of carbon fibers and expanded graphite stabilized from the addition of cellulose nanocrystals to produce highly conductive cellulose composites. ACS Sustain. Chem. Eng. 6(3), 3291–3298 (2018)

T.S. Tran, N.K. Dutta, N.R. Choudhury, Graphene inks for printed flexible electronics: graphene dispersions, ink formulations, printing techniques and applications. Adv. Coll. Interface. Sci. 261, 41–61 (2018)

J. Hou et al., Effective dispersion of multi-walled carbon nanotubes in aqueous solution using an ionic-gemini dispersant. J. Colloid Interface Sci. 512, 750–757 (2018)

L. Lin, H. Peng, G. Ding, Dispersion stability of multi-walled carbon nanotubes in refrigerant with addition of surfactant. Appl. Therm. Eng. 91, 163–171 (2015)

L. Yue et al., Epoxy composites with carbon nanotubes and graphene nanoplatelets—dispersion and synergy effects. Carbon 78, 268–278 (2014)

R.P. Tortorich, J.-W. Choi, Inkjet printing of carbon nanotubes. Nanomaterials 3(3), 453–468 (2013)

D. McManus et al., Water-based and biocompatible 2D crystal inks for all-inkjet-printed heterostructures. Nat. Nanotechnol. 12(4), 343–350 (2017)

K.-Y. Shin, J.-Y. Hong, J. Jang, Micropatterning of graphene sheets by inkjet printing and its Wideband Dipole-Antenna Application. Adv. Mater. 23(18), 2113–2118 (2011)

J.N. Israelachvili, Intermolecular and Surface Forces (Academic press, Cambridge, 2011).

V.S. Turkani et al., A highly sensitive printed humidity sensor based on a functionalized MWCNT/HEC composite for flexible electronics application. Nanoscale Adv. 1(6), 2311–2322 (2019)

O.-S. Kwon et al., Fabrication and characterization of inkjet-printed carbon nanotube electrode patterns on paper. Carbon 58, 116–127 (2013)

S. Shengbo et al., Highly sensitive wearable strain sensor based on silver nanowires and nanoparticles. Nanotechnology 29(25), 255202 (2018)

Y.Z.N. Htwe, I.N. Hidayah, M. Mariatti, Performance of inkjet-printed strain sensor based on graphene/silver nanoparticles hybrid conductive inks on polyvinyl alcohol substrate. J. Mater. Sci.: Mater. Electron. 31(18), 15361–15371 (2020)

Acknowledgements

The authors would like to thank the Universiti Sains Malaysia for their contribution to this project through Fundamental Research Grant (MRSA: Grant No.: 6071385).

Funding

The fund used for this study was provided by Universiti Sains Malaysia through Fundamental Research Grant (MRSA: Grant No.: 6071385).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Akindoyo, J.O., Ismail, N.H. & Mariatti, M. Development of environmentally friendly inkjet printable carbon nanotube‐based conductive ink for flexible sensors: effects of concentration and functionalization. J Mater Sci: Mater Electron 32, 12648–12660 (2021). https://doi.org/10.1007/s10854-021-05900-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-021-05900-y