Abstract

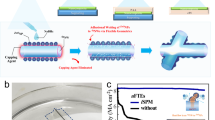

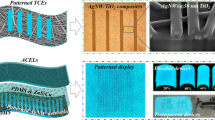

Flexible electronic devices entail highly transparent and conducting electrodes with excellent adherent and mechanically robust properties along with excellent bendability. Here, we report the development of transparent and conducting electrodes comprising silver nanowires (AgNWs) and amorphous-titanium oxide (a-TiOx) nanocomposite thin films. The AgNWs and a-TiOx nanocomposite thin films were deposited by a wire bar coating process, a scalable and high throughput procedure. PXRD analysis confirmed the crystalline and amorphous nature for AgNWs and TiOx thin film, respectively. FE-SEM and HRTEM analyses revealed the core–shell nature of the composite where AgNWs and a-TiOx acted as core and shell, respectively. Even after three-layer coating of AgNWs-a-TiOx nanocomposite thin films, high transparency (~ 77%) in the visible region (400–800 nm) and a sheet resistance of 23 Ω/sq were observed. Furthermore, tape peel off tests were conducted for AgNWs and AgNWs-a-TiOx nanocomposite, which displayed high adherence for the three-layer coated AgNWs-a-TiOx nanocomposite as compared with AgNWs alone. The formation of AgNWs-a-TiOx core–shell structure enhances the intra-particle binding and network formation of AgNWs. The preliminary studies highlight that the developed AgNWs-a-TiOx nanocomposite thin films have great potential as transparent electrodes for realizing scalable cost-effective flexible electronic devices.

Similar content being viewed by others

References

A. Kim, Y. Won, K. Woo, C.H. Kim, J. Moon, ACS Nano 7, 1081–1091 (2013). https://doi.org/10.1021/nn305491x

Y. Wang, P. Liu, H. Wang, B. Zeng, J. Wang, F. Chi, J. Mater. Sci. 54, 2343–2350 (2019). https://doi.org/10.1007/s10853-018-2986-9

S. Chen, Y. Guan, Y. Li, X. Yan, H. Ni, L. Li, J. Mater. Chem. C 5, 2404–2414 (2017). https://doi.org/10.1039/C6TC05000J

S. Cho, S. Kang, A. Pandya, R. Shanker, Z. Khan, Y. Lee, J. Park, S.L. Craig, H. Ko, ACS Nano 11, 4346–4357 (2017). https://doi.org/10.1021/acsnano.7b01714

C. Lee, Y. Oh, I.S. Yoon, S.H. Kim, B.K. Ju, J.M. Hong, Sci. Rep. 8, 2763 (2018). https://doi.org/10.1038/s41598-018-20368-3

H. Gu, C. Guo, S. Zhang, L. Bi, T. Li, T. Sun, S. Liu, ACS Nano 12, 559–567 (2018). https://doi.org/10.1021/acsnano.7b07360

D.J. Lee, Y. Oh, J.M. Hong, Y.W. Park, B.K. Ju, Sci. Rep. 8, 14170 (2018). https://doi.org/10.1038/s41598-018-32590-0

B.H. Bae, S. Jun, M.S. Kwon, Y.W. Park, C.J. Han, S. Kim, B.K. Ju, Opt. Mater. 92, 87–94 (2019). https://doi.org/10.1016/j.optmat.2019.04.007

H. Liu, V. Aurutin, N. Izyumskaya, U. Ozgur, H. Morkoc, Superlattices Microstruct. 48, 458–484 (2010). https://doi.org/10.1016/j.spmi.2010.08.011

M. Loknac, R. Eggert, M. Redlinger, The availability of Indium: the present, medium term, and long term, National Renewable Laboratory (NREL), USA. https://www.nrel.gov/docs/fy16osti/62409.pdf

S.C. Dixon, D.O. Scanlon, C.J. Carmalt, I.P. Parkin, J. Mater. Chem. C 4, 6946 (2016). https://doi.org/10.1039/C6TC01881E

D.P. Tran, H. Lu, C.K. Lin, Coatings 8, 212 (2016). https://doi.org/10.3390/coatings8060212

X. Shen, M. Yang, C. Zhang, Z. Qiao, H. Wang, C. Tang, Superlattices Microstruct. 123, 251–256 (2018). https://doi.org/10.1016/j.spmi.2018.09.001

T. Sannicolo, M. Lagrange, A. Cabos, C. Celle, J.P. Simonato, D. Bellet, Small 12, 6052–6075 (2016). https://doi.org/10.1002/smll.201602581

S. Coskun, E.S. Ates, H.E. Unalan, Nanotechnology 24, 125202 (2013). https://doi.org/10.1088/0957-4484/24/12/125202

B. Zheng, Q. Zhu, Y. Zhao, J. Mater. Sci. 54, 5802–5812 (2019). https://doi.org/10.1007/s10853-018-03235-4

M.X. Jing, M. Li, C.Y. Chen, Z. Wang, X.Q. Shen, J. Mater. Sci. 50, 6437–6443 (2015). https://doi.org/10.1007/s10853-015-9198-3

Y. Tao, D. Pan, Mater. Res. Express 6, 076430 (2019). https://doi.org/10.1088/2053-1591/ab17a4

B.T. Liu, S.X. Huang, RSC Adv. 4, 59226–59232 (2014). https://doi.org/10.1039/C4RA11660G

L. Miao, G. Liu, K. McEleney, J. Wang, J. Mater. Sci. 54, 10355–10370 (2019). https://doi.org/10.1007/s10853-019-03507-7

S. Kim, S.Y. Kim, M.H. Chung, J. Kim, J.H. Kim, J. Mater. Chem. C3, 5859–5868 (2015). https://doi.org/10.1039/C5TC00801H

P. Kumar, F. Shahzad, S.M. Hong, C.M. Koo, RSC Adv. 6, 101283–101287 (2016). https://doi.org/10.1039/C6RA18652A

F. Alotaibi, T.T. Tuang, M.J. Nine, C.J. Coghlan, D. Losic, A.C.S. Appl, Nano Mater. 1, 2249–2260 (2018). https://doi.org/10.1021/acsanm.8b00255

M.C. Han, H.W. He, B. Zhang, X.X. Wang, J. Zhang, M.H. You, S.Y. Yan, Y.Z. Long, Mater. Res. Express 4, 075043 (2017). https://doi.org/10.1088/2053-1591/aa7c13

Y. Huang, Y. Tian, C. Hang, Y. Liu, S. Wang, M. Qi, H. Zhang, Q. Peng, A.C.S. Appl, Nano Mater. 2, 2456–2466 (2019). https://doi.org/10.1021/acsanm.9b00337

X. Zhang, J. Wu, J. Wang, Q. Yang, B. Zhang, Z. Xie, A.C.S. Appl, Mater. Interfaces 8, 34630–34637 (2016). https://doi.org/10.1021/acsami.6b11978

E. Lee, J. Ahn, H.C. Kwon, S. Ma, K. Kim, S. Yun, J. Moon, Adv. Energy Mater. 8, 1702182 (2018). https://doi.org/10.1002/aenm.201702182

A. Kim, Y. Won, K. Woo, S. Jeong, J. Moon. Adv. Funct. Mater. 24, 2462–2471 (2014). https://doi.org/10.1002/adfm.201303518

M. Singh, P. Prasher, J. Kim, Nano-Structured & Nano-Objects 16, 151–155 (2018). https://doi.org/10.1016/j.nanoso.2018.05.009

M.B. Gawande, A. Goswami, T. Asefa, H. Guo, A.V. Biradar, D.L. Peng, R. Zboril, R.S. Varma, Chem. Soc. Rev. 44, 7540–7590 (2015). https://doi.org/10.1039/C5CS00343A

Y. Hou, Y. Liu, R. Gao, Q. Li, H. Guo, A. Goswami, R. Zboril, M.B. Gawande, X. Zou, ACS Catal. 7, 7038–7042 (2017). https://doi.org/10.1021/acscatal.7b02341

A. Goswami, A.K. Rathi, C. Aparicio, O. Tomanec, M. Petr, R. Pocklanova, M.B. Gawande, R.S. Varma, R. Zboril, A.C.S. Appl, Mater. Interfaces 9, 2815–2824 (2017). https://doi.org/10.1021/acsami.6b13138

A.K. Rathi, H. Kmentová, A. Naldoni, A. Goswami, M.B. Gawande, R.S. Varma, S. Kment, R. Zbořil, ACS Appl. Nano Mater. 1, 2526–2535 (2018). https://doi.org/10.1021/acsanm.8b00078

V.C. Anitha, A. Goswami, H. Sopha, D. Nandan, M.B. Gawande, K. Cepe, S. Ng, R. Zboril, J.M. Macak, Appl. Mater. Today 10, 86–92 (2018). https://doi.org/10.1016/j.apmt.2017.12.006

S. Panimalar, R. Uthrakumar, E. TamilSelvi, P. Gomathy, C. Inmozhi, K. Kaviyarasu, J. Kennedy, Surf. Interfaces 20, 100512 (2020). https://doi.org/10.1016/j.surfin.2020.100512

K. Kaviyarasu, C. Maria Magdalane, D. Jayakumar, Y. Samson, A.K.H. Bashir, M. Maaza, D. Letsholathebe, A.H. Mahmoud, J. Kennedy, J. King Saud Uni. Sci. 32, 1516–1522 (2020). https://doi.org/10.1016/j.jksus.2019.12.006

Y. Wang, L.T. Tseng, P.P. Murmu, N. Bao, J. Kennedy, M. Ionesc, J. Ding, K. Suzuki, S. Li, J. Yi, Mater. Des. 121, 77–84 (2017). https://doi.org/10.1016/j.matdes.2017.02.037

K. Kasinathan, J. Kennedy, M. Elayaperumal, M. Henini, M. Malik, Sci. Rep. 6, 38064 (2016). https://doi.org/10.1038/srep38064

M.C. Mbambo, S. Khamlich, T. Khamliche, M.K. Moodley, K. Kaviyarasu, I.G. Madiba, M.J. Madito, M. Khenfouch, J. Kennedy, M. Henini, E. Manikandan, M. Maaza, Sci. Rep. 10, 10982 (2020). https://doi.org/10.1038/s41598-020-67418-3

J. Wang, M. Liang, Y. Fang, T. Qiu, J. Zhang, L. Zhi, Adv. Mater. 24, 2874 (2012). https://doi.org/10.1002/adma.201200055

W.J. Lee, W.T. Park, S. Park, S. Sung, Y.Y. Noh, M.H. Yoon, Adv. Mater. 27, 5043–5048 (2015). https://doi.org/10.1002/adma.201502239

D.J. Kim, H.I. Shin, E.H. Ko, K.H. Kim, T.W. Kim, H.K. Kim, Sci. Rep. 6, 34322 (2016). https://doi.org/10.1038/srep34322

S. Cho, K. Lee, A.J. Heeger, Adv. Mater. 21, 1941 (2009). https://doi.org/10.1002/adma.200803013

P. Divya, S. Arulkumar, S. Parthiban, A. Goswami, T. Ahamad, M.B. Gawande, Molecules 25, 1683 (2020). https://doi.org/10.3390/molecules25071683

S. Arulkumar, S. Parthiban, A. Goswami, R.S. Varma, M. Naushad, M.B. Gawande, Mater. Res. Express 6, 126427 (2019). https://doi.org/10.1088/2053-1591/ab5eed

X. Xia, B. Yang, X. Zhang, C. Zhou, Mater. Res. Express 2, 075009 (2015). https://doi.org/10.1088/2053-1591/2/7/075009

Z. Nengduo, Y. Xuesonga, G. Hao, RSC Adv. 6, 47552–47561 (2016). https://doi.org/10.1039/C6RA05448J

M. Hannula, H. Ali-Löytty, K. Lahtonen, E. Sarlin, J. Saari, M. Valden, Chem. Mater. 30, 1199–1208 (2018). https://doi.org/10.1021/acs.chemmater.7b02938

P. Ramasamy, D.M. Seo, S.H. Kim, J. Kim, J. Mater. Chem. 22, 11651–11657 (2012). https://doi.org/10.1039/C2JM00010E

J.L.G. Fierro, M.A. Peña, L.G. Tejuca, J. Mater. Sci. 23, 1018–1023 (1988). https://doi.org/10.1007/BF01154005

S.J. Yuan, F.J. Xu, S.O. Pehkonen, Y.P. Ting, E.T. Kang, K.G. Neoh, J. Electrochem. Soc. 155, C196–C210 (2008). https://doi.org/10.1149/1.2885073

Acknowledgements

The authors are thankful to the Department of Science and Technology-Science and Engineering Research Board, Government of India for financial support under the early career research award (File No. ECR/2016/000785). The author (SMA) thanks to Researchers Supporting Project number (RSP-2020/29), King Saud University, Riyadh, Saudi Arabia. The author T. S. is thankful to PSG Son’s and Charities Fellowship for providing financial support.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Arulkumar, S., Senthilkumar, T., Parthiban, S. et al. AgNWs-a-TiOx: a scalable wire bar coated core–shell nanocomposite as transparent thin film electrode for flexible electronics applications. J Mater Sci: Mater Electron 32, 6454–6464 (2021). https://doi.org/10.1007/s10854-021-05362-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-021-05362-2