Abstract

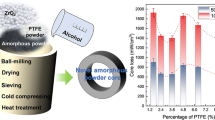

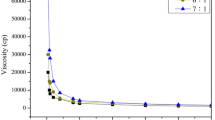

A molded-type coil is prepared by filling and dry pressing granulated alloy magnetic powders directly onto enameled wire. As the molded-type coil is developed toward miniaturization, the granules consisting of magnetic powder and organic binder cannot uniformly fill the small space in the coil center column during molding. This leads to a porous microstructure or cracks. In this study, magnetic alloy powder coils were prepared using a screen-printing process using high-solid-content magnetic pastes. The magnetic powder was surface-modified with titanate coupling agent to improve the magnetic powder and epoxy resin compatibility, thereby improving magnetic powder mixing with epoxy resin and reducing the high solid content magnetic paste viscosity. The experimental results showed that the relative density and magnetic properties (such initial permeability, core loss, and coercivity) can be significantly enhanced using titanate coupling agent surface modification.

Similar content being viewed by others

References

H.I. Hsiang, L.F. Fan, K.T. Ho, J. Magn. Magn. Mater. 444, 1–6 (2017)

H.I. Hsiang, L.F. Fan, K.T. Ho, IEEE Tran. Magn. 54, 2000407 (2018)

Y.P. Wu, H.Y. Chiang, H.I. Hsiang, AIP Adv. 8, 085006 (2018)

Y.P. Wu, H.Y. Chiang, H.I. Hsiang, J. Mater. Sci. Mater. Electron. 30, 8080–8088 (2019)

H.I. Hsiang, L.F. Fan, J.J. Hung, J. Magn. Magn. Mater. 490, 165532 (2019)

H.I. Hsiang, L.F. Fan, J.J. Hung, J. Magn. Magn. Mater. 447, 1–8 (2018)

L.F. Fan, H.I. Hsiang, J.J. Hung, Appl. Surf. Sci. 433, 133–138 (2018)

W.S. Chen, Y.L. Chang, H.I. Hsiang, F.C. Hsu, F.S. Yen, Ceram. Int. 37, 2347–2352 (2011)

A.H. Taghvaei, H. Shokrollahi, A. Ebrahimi, K. Janghorban, Mater. Chem. Phys. 116, 247–253 (2009)

H.I. Hsiang, C.C. Chen, J.Y. Tsai, Appl. Surf. Sci. 245, 252–259 (2005)

H.I. Hsiang, J.Y. Tsai, J. Mater. Sci. 41, 6339–6346 (2006)

Y. Zhang, T. Suga, M. Kawasaki, X.X. Tang, N. Uchida, K. Uematsu, J. Am. Ceram. Soc. 79, 435–440 (1996)

Y. Duan, S. Gu, Z. Zhang, M. Wen, J. Alloys Compd. 542, 90–96 (2012)

T.Y. Byun, S.C. Byeon, K.S. Hong, C.K. Kim, IEEE Trans. Magn. 35, 3445–3447 (1999)

S.U. Jan, C.J. Wang, J. Appl. Phys. 64, 4627–4631 (1988)

H. Shokrollahi, K. Janghorban, J. Mater. Process. Technol. 189, 1–12 (2007)

N.A. Castro, F.J.G. Landgraf, Soft Magn. Mater. Conf. 1, 767–772 (2003)

L.P. Lefebvre, S. Pelletier, C. Gélinas, J. Magn. Magn. Mater. 176, L93–L96 (1977)

H. Su, H. Zhang, X. Tang, B. Liu, Z. Zhong, Phys. B 405, 4006–4009 (2010)

Acknowledgements

This work was supported by the Ministry of Science and Technology, Taiwan [106-2923-E-006 -009 -MY3 and 109-3111-8-006 -001].

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Hsiang, HI., Chuang, KH. & Lee, WH. Titanate coupling agent surface modification effect on the magnetic properties of iron-based alloy powder coil prepared using screen printing. J Mater Sci: Mater Electron 32, 1800–1807 (2021). https://doi.org/10.1007/s10854-020-04948-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-020-04948-6