Abstract

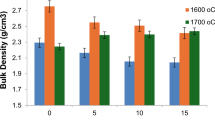

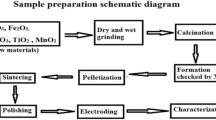

B-site oxide precursor method was utilized to synthesize Ba3MgNb2O9 ceramics. The effects of sintering temperature on phase composition of Ba3MgNb2O9 ceramics was evaluated by the X-ray diffraction. Experimental results indicated that all prepared Ba3MgNb2O9 ceramics exhibited 1:2 ordered hexagonal structure. The second phase Ba5Nb4O15 can emerge in all ceramics due to the decrease of activation energy of reaction, leading to the splitting of Eg(O) vibration mode in the Raman spectra. In addition, lattice parameters of 1:2 ordered phase were obtained from the refinement of XRD patterns. The maximum value of c/a ratio occurred at 1475 °C, meanwhile the ceramics showed the highest 1:2 ordered degree and excellent Q × f. It was also found that the uniform grain-size distribution of Ba3MgNb2O9 powder were important factors for preparing dense Ba3MgNb2O9 ceramics. Moreover, B-site oxide precursor method can not only effectively lower the densification temperature from 1650 to 1475 °C, but also increase the quality factor (Q × f) by about 90.8%, i.e., from 55,277 to 105,467 GHz.

Similar content being viewed by others

References

E. Bjornson, L. Sanguinetti, H. Wymeersch, J. Hoydis, T.L. Marzetta, Digit. Signal. Process. 94, 3–20 (2019)

F. Boccardi, R.W. Heath, A. Lozano, T.L. Marzetta, P. Popovski, IEEE. Commun. Mag. 52, 74–80 (2013)

X. Wang, K.L. Wu, IEEE. T. Microw. Theory. 62, 275–281 (2014)

D. Zhou, L.X. Pang, D.W. Wang, C. Li, B.B. Jin, I.M. Reaney, J. Mater. Chem. C. 5, 10094–10098 (2017)

H.F. Cheng, C.T. Chia, H.L. Liu, M.Y. Chen, Y.T. Tzeng, I.N. Lin, J. Eur. Ceram. Soc. 27, 2893–2897 (2017)

S. Manivannan, A. Joseph, P.K. Sharma, K.C.J. Raju, D. Das, Ceram. Int. 41, 10923–10933 (2015)

Y. Bisht, R. Tomar, P. Abhilash, D.R. Lekshmi, M. Thirumal, B. Mater, Sci. 40, 1165–1170 (2017)

M.S. Fu, X.Q. Liu, X.M. Chen, Y.W. Zeng, J. Am. Ceram. Soc. 93, 787–795 (2010)

C.T. Lee, Y.C. Lin, C.Y. Huang, C.Y. Su, C.L. Hu, J. Am. Ceram. Soc. 90, 483–489 (2007)

A. Dias, R.L. Moreira, J. Appl. Phys. 94, 3414–3421 (2003)

J.B. Lim, J.O. Son, S. Nahm, W.S. Lee, M.J. Yoo, N.G. Gang, H.J. Lee, Y.S. Kim, Jpn. J. Appl. Phys. 43, 5388–5391 (2004)

S.L. Swartz, T.R. Shrout, Mat. Res. Bull. 17, 1245–1250 (1982)

C.C. Tsai, S.Y. Chu, C.K. Liang, J. Alloy. Com. 478, 516–522 (2009)

O. Khamman, R. Yimnirun, S. Ananta, J. Alloy. Com. 465, 522–526 (2008)

G. Robert, M.D. Maeder, D. Damjanovic, N. Setter, J. Am. Ceram. Soc. 84, 2869–2872 (2001)

J. Rodriguez-Carvajal, Int. Union Crystallogr. Newslett. 26, 12–19 (2001)

B.W. Hakki, P.D. Coleman, I.R.E. Trans, Microw. Theory Tech. 8, 402–410 (1960)

W.E. Courtney, IEEE Trans. Microw. Theory Tech. 18, 476–485 (1970)

Y.W. Kim, J.H. Park, J.G. Park, J. Eur. Ceram. Soc. 24, 1775–1779 (2004)

S.B. Desu, H.M. O’Bryan, J. Am. Ceram. Soc. 68, 546–551 (1985)

D.W. Kim, J.R. Kim, S.H. Yoon, K.S. Hong, J. Am. Ceram. Soc. 85, 2759–2762 (2002)

J.X. Liu, Y.M. Kan, G.J. Zhang, J. Am. Ceram. Soc. 93, 370–373 (2010)

P.P. Ma, H. Gu, X.M. Chen, J. Mater. Chem. C. 3, 10755–10760 (2015)

Y.X. Shi, J. Shen, J. Zhou, J. Xu, W. Chen, Y.Y. Qi, L. Jiao, Ceram. Int. 41, 253–257 (2015)

B.K. Kim, H. Hamaguchi, I.T. Kim, K.S. Hong, J. Am. Ceram. Soc. 78, 3117–3120 (1995)

H. Zhang, C.L. Diao, S.L. Liu, S.Z. Jiang, F. Shi, X.P. Jing, J. Alloy. Com. 587, 717–723 (2014)

A. Dias, F.M. Matinaga, R.L. Moreira, Chem. Mater. 19, 2335–2341 (2007)

F. Shi, H. Dong, J. Appl. Phys. 111, 014111 (2012)

T.L. Sun, X.M. Chen, Aip. Adv. 5, 017106 (2015)

I.G. Siny, R.W. Tao, R.S. Katiyar, R.A. Guo, A.S. Bhalla, J. Phys. Chem. Solids. 59, 181–195 (1998)

T. Kolodiazhnyi, J. Padchasri, R. Yimnirum, J. Eur. Ceram. Soc. 38, 1517–1523 (2018)

C.T. Lee, C.Y. Huang, Y.C. Lin, J. Yang, J. Am. Ceram. Soc. 90, 3148–3155 (2007)

H. Zhang, C.L. Diao, S.L. Liu, S.Z. Jiang, X.P. Jing, F. Shi, Ceram. Int. 40, 2427–2434 (2014)

P.F. Ning, L.X. Li, P. Zhang, W.S. Xia, Ceram. Int. 38, 1391–1398 (2012)

M.Y. Chen, C.T. Chia, I.N. Lin, L.J. Lin, C.W. Ahn, S. Nahm, J. Eur. Ceram. Soc. 26, 1965–1968 (2006)

H. Wang, C.E. Huang, Q. Deng, L. Zhao, C.Y. Shen, Ceram. Int. 44, 8700–8705 (2018)

Acknowledgement

This work is supported by the Department of Education’s Production-Study-Research combined innovation Funding-“Blue fire plan (Huizhou)” (No. CXZJHZ201733), and Natural Science Foundation of Shandong Province (ZR2018LE003).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wang, H., Fu, R., Liu, X. et al. Low temperature sintered of Ba3MgNb2O9 ceramics with high quality factor via B-site oxide precursor method. J Mater Sci: Mater Electron 31, 20245–20254 (2020). https://doi.org/10.1007/s10854-020-04544-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-020-04544-8